Array substrate, manufacturing method thereof, liquid crystal display panel and liquid crystal display device

A technology of an array substrate and a manufacturing method, applied in the field of liquid crystal display, can solve the problem of large viewing angle deviation of liquid crystal displays, and achieve the effect of improving the large viewing angle deviation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

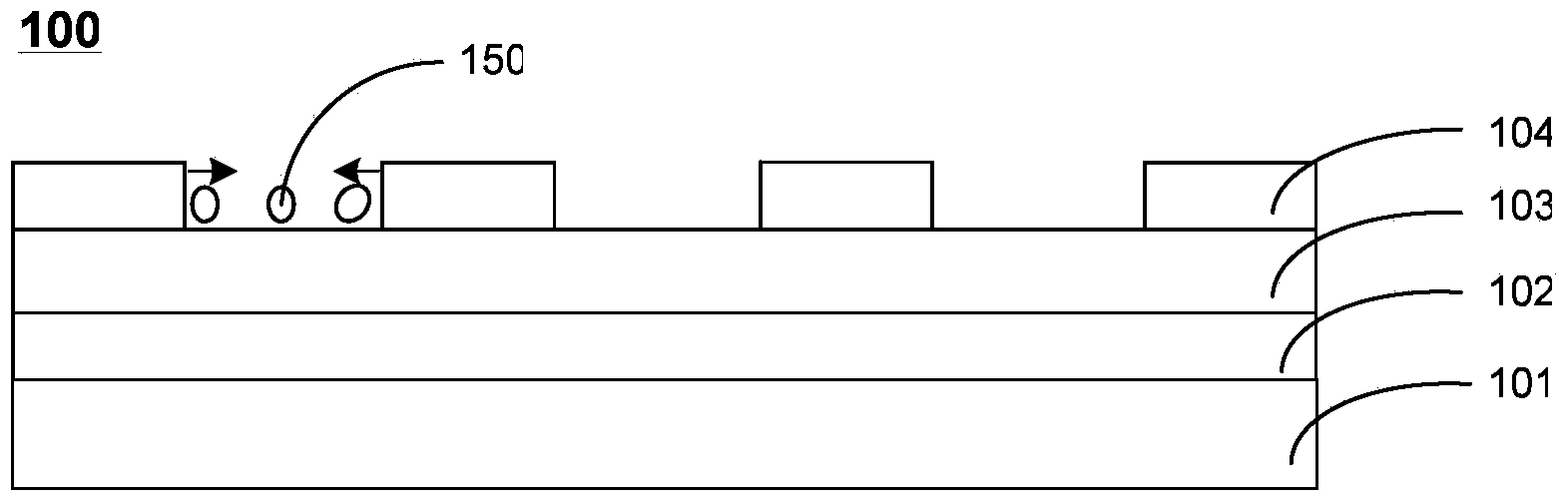

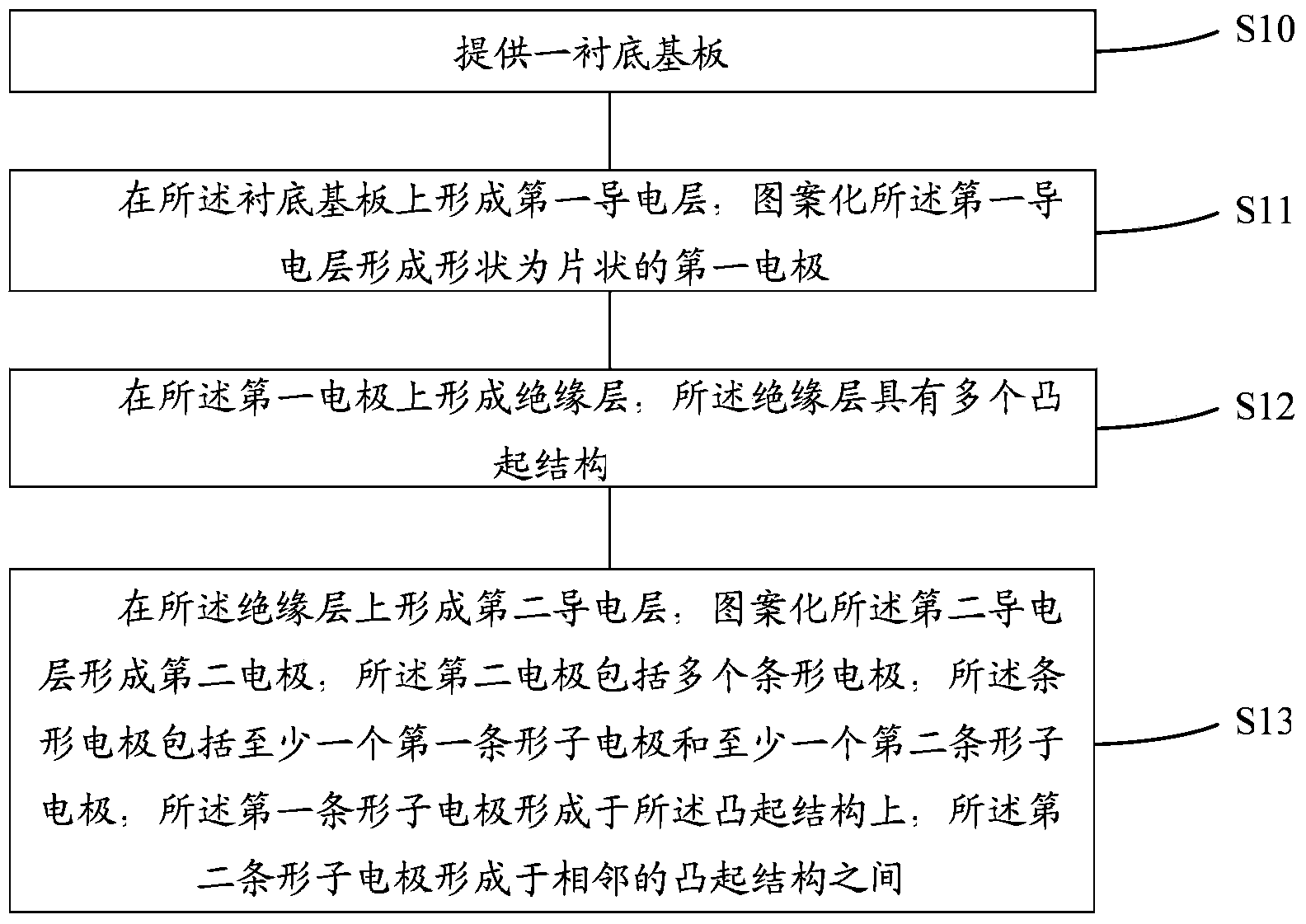

[0031] Please refer to Figure 3d , which is a partial structural diagram of the array substrate of the embodiment of the present invention. Such as Figure 3d As shown, the array substrate 200 includes: a base substrate 201 and a plurality of pixel units located on the base substrate 201, each pixel unit includes a first electrode 202, an insulating layer 203 and a second electrode stacked in sequence 204, a fringe field is formed between the first electrode 202 and the second electrode 202; wherein, the shape of the first electrode 202 is a sheet, and the second electrode 204 includes a plurality of strip electrodes, the The strip-shaped electrodes include at least one first strip-shaped sub-electrode 205 and at least one second strip-shaped sub-electrode 206, and the distance between the first strip-shaped sub-electrode 205 and the base substrate 201 is the same as that of the second strip-shaped sub-electrode 205. The distances between the electrodes 206 and the base sub...

Embodiment 2

[0053] Please refer to Figure 5d , which is a partial structural diagram of the array substrate of the embodiment of the present invention. Such as Figure 5d As shown, the array substrate 300 includes: a base substrate 301 and a plurality of pixel units located on the base substrate 301, each pixel unit includes a first electrode 302, an insulating layer 303 and a second electrode stacked in sequence 304, forming a fringe field between the first electrode 302 and the second electrode 302; wherein, the shape of the first electrode 302 is a sheet, and the second electrode 304 includes a plurality of strip electrodes, the The strip electrode includes at least one first strip sub-electrode 305 and at least one second strip sub-electrode 306, the distance between the first strip sub-electrode 305 and the base substrate 301 is the same as that of the second strip sub-electrode 305. The distances between the electrodes 306 and the base substrate 301 are not equal.

[0054] The d...

Embodiment 3

[0065] Please refer to Figure 7d , which is a partial structural diagram of the array substrate of the embodiment of the present invention. Such as Figure 7d As shown, the array substrate 400 includes: a base substrate 401 and a plurality of pixel units located on the base substrate 401, each pixel unit includes a first electrode 402, an insulating layer 403 and a second electrode stacked in sequence 404, a fringe field is formed between the first electrode 402 and the second electrode 402; wherein, the shape of the first electrode 402 is a sheet, and the second electrode 404 includes a plurality of strip electrodes, the The strip-shaped electrodes include at least one first strip-shaped sub-electrode 405 and at least one second strip-shaped sub-electrode 406, and the distance between the first strip-shaped sub-electrode 405 and the base substrate 401 is the same as that of the second strip-shaped sub-electrode 405. The distances between the electrodes 406 and the base sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com