Method for building SMT welding spot IMC thermal fatigue probability failure physical model

A technology of probabilistic fault physics and physical models, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

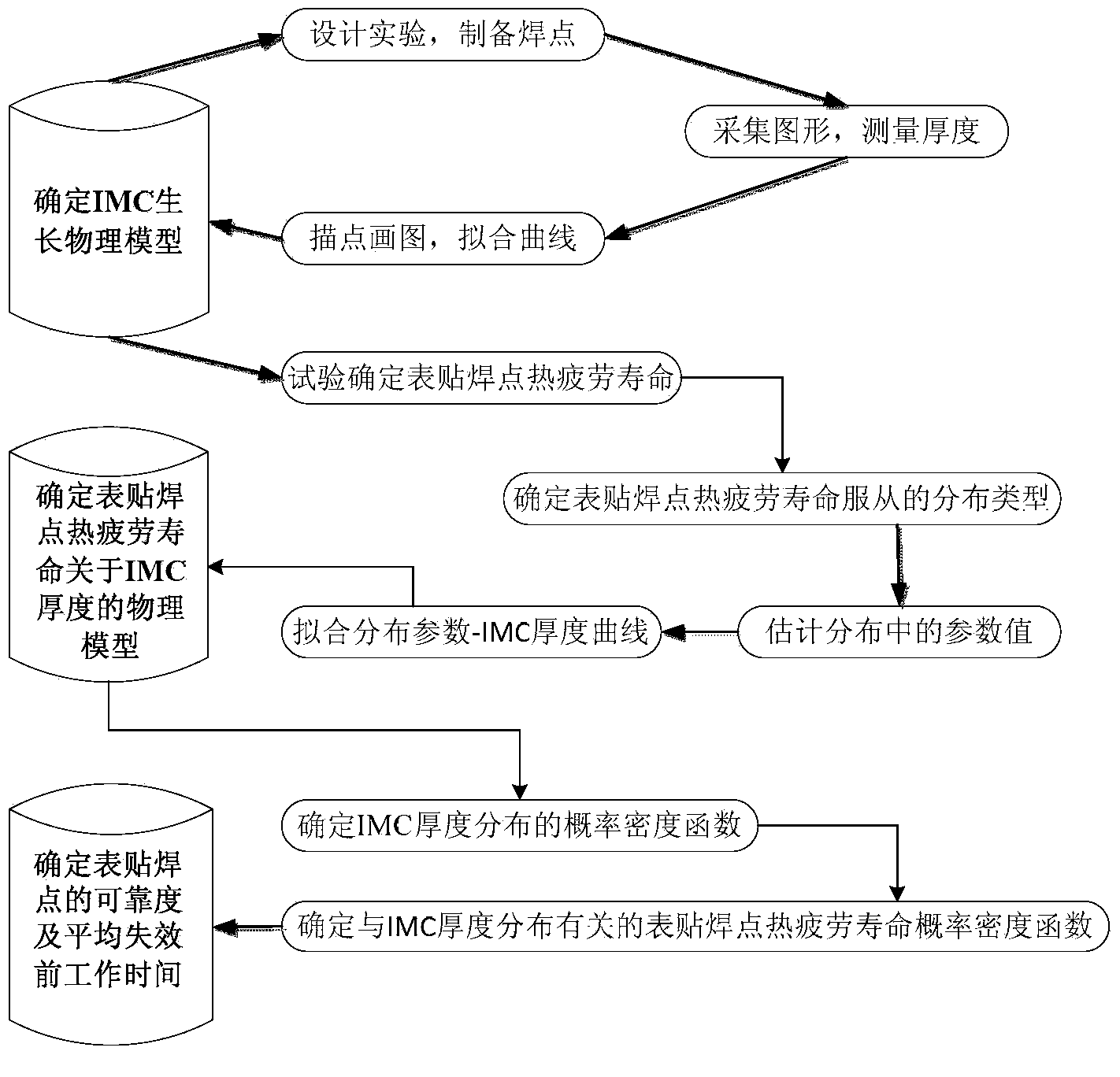

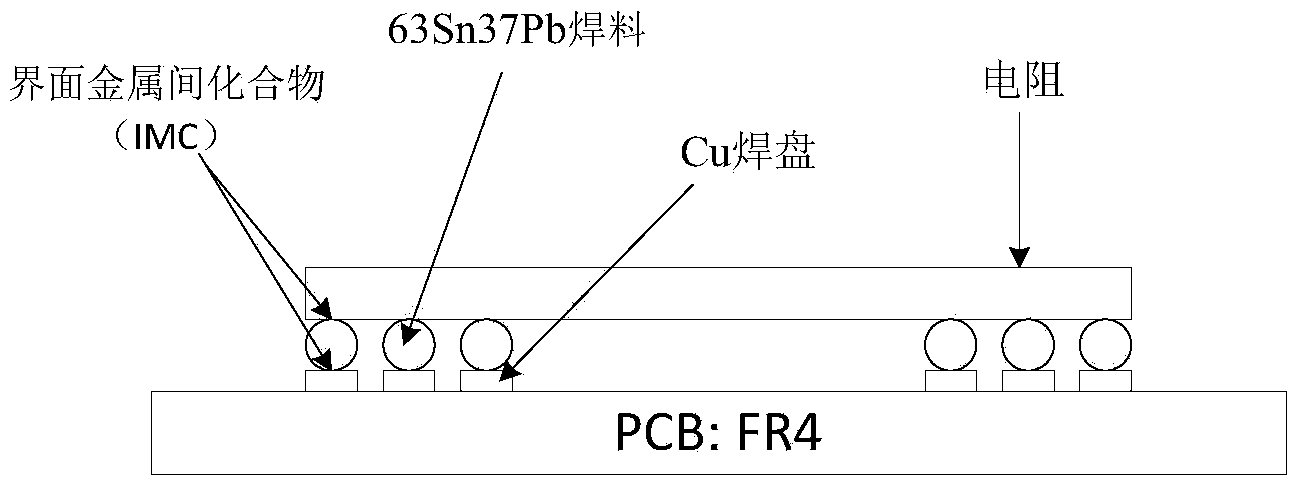

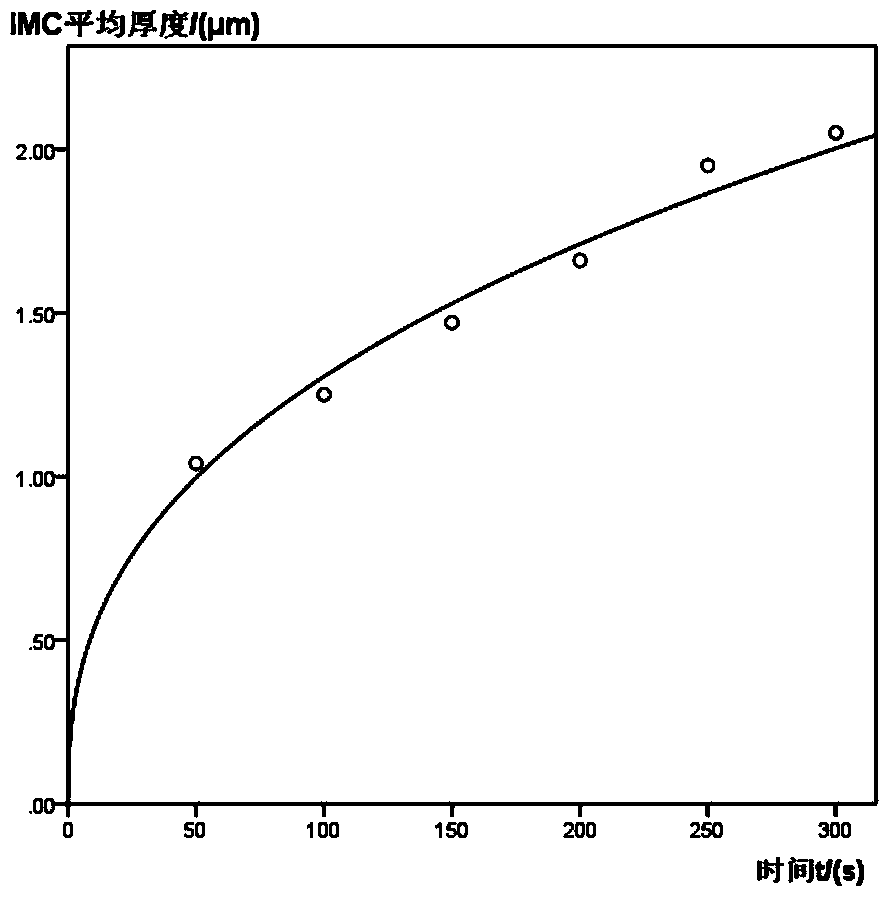

[0053] The following example is a probabilistic analysis of the thermal fatigue failure mechanism of the surface-mounted solder joints of the chip component 1206, mainly including establishing the IMC growth model, determining the functional relationship between the thickness of the IMC and the thermal fatigue life of the surface-mounted solder joints, and obtaining the welding process, The probabilistic failure physical model between the working conditions of surface-mount solder joints and the thermal fatigue life of surface-mount solder joints determines the reliability and average working time before failure of surface-mount solder joints.

[0054] A method for establishing a surface-mounted solder joint IMC thermal fatigue probability failure physical model of the present invention, such as figure 1 As shown, the specific steps are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com