Double-laser head dust detection method and sensor

A detection sensor and detection method technology, which is used in measurement devices, scientific instruments, suspension and porous material analysis, etc. Reduce the probability of equipment life and the effect of average working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

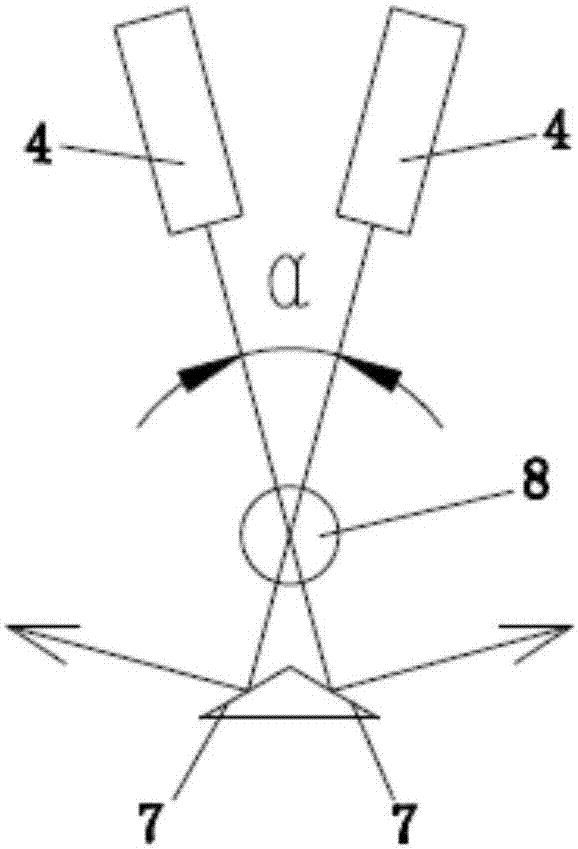

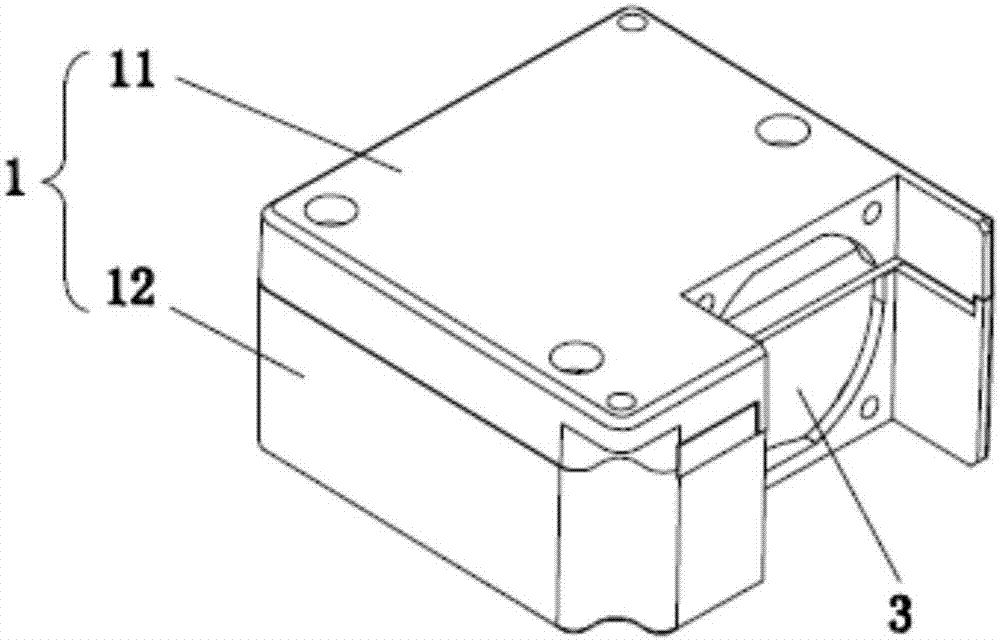

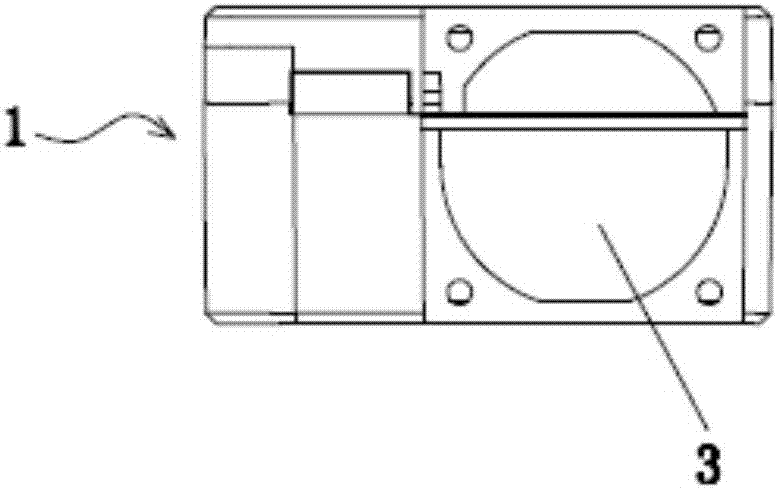

[0040] The specific embodiment of the present invention is as Figure 1 to Figure 11 As shown, a double laser head dust detection method, when using the light scattering method to detect the dust mass concentration in the air, two laser heads 4 are used to alternately emit laser light to the air in the same detection area, and the laser light is shot into the detection area Scattering occurs on the dust, the scattered laser light is captured by the photoelectric receiver 8 located on one side of the detection area, and the laser light passing through the detection area is reflected to other directions except the detection area by the reflective surface 7.

[0041] Such as figure 1 As shown, the angle between the laser emitting directions of the two laser heads 1 is α, and the range of α is 30-45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com