A kind of agricultural tire sidewall rubber filled with tire reclaimed rubber

A technology of reclaimed rubber and sidewall rubber, applied in the field of tire manufacturing, can solve the problems of poor wetting ability of compounding agents, narrow relative molecular chain distribution, large expansion rate of semi-finished products, etc. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

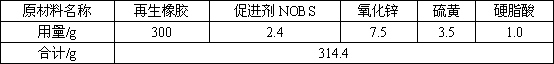

Method used

Image

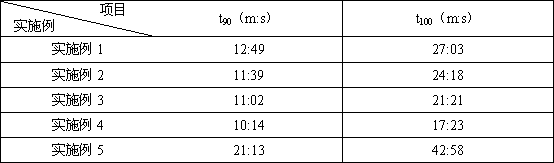

Examples

Embodiment 1

[0017] An agricultural tire sidewall rubber filled with tire reclaimed rubber, which includes the following raw materials and their parts by mass:

[0018] 20# standard rubber, 20 parts; butadiene rubber 9000, 20 parts; styrene-butadiene rubber 1502, 30 parts; tire reclaimed rubber (TRR), 30 parts; zinc oxide, 4.0 parts; stearic acid, 3.0 parts; antioxidant 4020 , 2.0 parts; antioxidant RD, 1.0 parts; protective wax, 2.5 parts; high wear-resistant carbon black N330, 25 parts; general carbon black, 35 parts; aromatic oil, 4.0 parts; pine tar, 3.0 parts; Coumarone, 3.0 parts; sulfur, 1.6 parts; accelerator NOBS, 0.8 parts; uniform dispersant MS, 0.8 parts.

[0019] The sum of the mass parts of styrene-butadiene rubber 1502 and tire reclaimed rubber is 60 parts.

[0020] The sum of the mass parts of 20# standard rubber and butadiene rubber 9000 is 40 parts.

[0021] Preparation method: Adopt one-stage mixing method: first mix NR, BR, SBR, TRR normally, then add 35 parts of gene...

Embodiment 2

[0024] An agricultural tire sidewall rubber filled with tire reclaimed rubber, which includes the following raw materials and their parts by mass:

[0025] 20# standard rubber, 20 parts; butadiene rubber 9000, 20 parts; styrene-butadiene rubber 1502, 20 parts; tire reclaimed rubber (TRR), 40 parts; zinc oxide, 4.0 parts; stearic acid, 3.0 parts; antioxidant 4020 , 2.0 parts; antioxidant RD, 1.0 parts; protective wax, 2.5 parts; high wear-resistant carbon black N330, 25 parts; general carbon black, 35 parts; aromatic oil, 4.0 parts; pine tar, 3.0 parts; Coumarone, 3.0 parts; sulfur, 1.6 parts; accelerator NOBS, 0.8 parts; uniform dispersant MS, 0.8 parts.

[0026] The sum of the mass parts of styrene-butadiene rubber 1502 and tire reclaimed rubber is 60 parts.

[0027] The sum of the mass parts of 20# standard rubber and butadiene rubber 9000 is 40 parts.

[0028] Its preparation method is with embodiment 1.

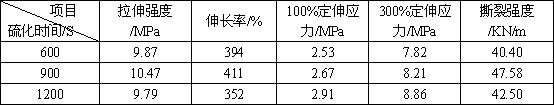

[0029] The vulcanization characteristics of the agricultural tire...

Embodiment 3

[0031] An agricultural tire sidewall rubber filled with tire reclaimed rubber, which includes the following raw materials and their parts by mass:

[0032] 20# standard rubber, 20 parts; butadiene rubber 9000, 20 parts; styrene-butadiene rubber 1502, 10 parts; tire reclaimed rubber (TRR), 50 parts; zinc oxide, 4.0 parts; stearic acid, 3.0 parts; antioxidant 4020 , 2.0 parts; antioxidant RD, 1.0 parts; protective wax, 2.5 parts; high wear-resistant carbon black N330, 25 parts; general carbon black, 35 parts; aromatic oil, 4.0 parts; pine tar, 3.0 parts; Coumarone, 3.0 parts; sulfur, 1.6 parts; accelerator NOBS, 0.8 parts; uniform dispersant MS, 0.8 parts.

[0033] The sum of the mass parts of styrene-butadiene rubber 1502 and tire reclaimed rubber is 60 parts.

[0034] The sum of the mass parts of 20# standard rubber and butadiene rubber 9000 is 40 parts.

[0035] Its preparation method is with embodiment 1.

[0036] The vulcanization characteristics of the agricultural tire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com