Method for preparing medicine taste-masking preparation from acrylic resin mixed aqueous dispersion

A technology of acrylic resin and water mixing, which is applied in the direction of pharmaceutical formulation, drug delivery, and medical preparations of non-active ingredients, etc. It can solve the problems of high coating weight gain, pollution of the environment, and insufficient flexibility to achieve good resistance to external forces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

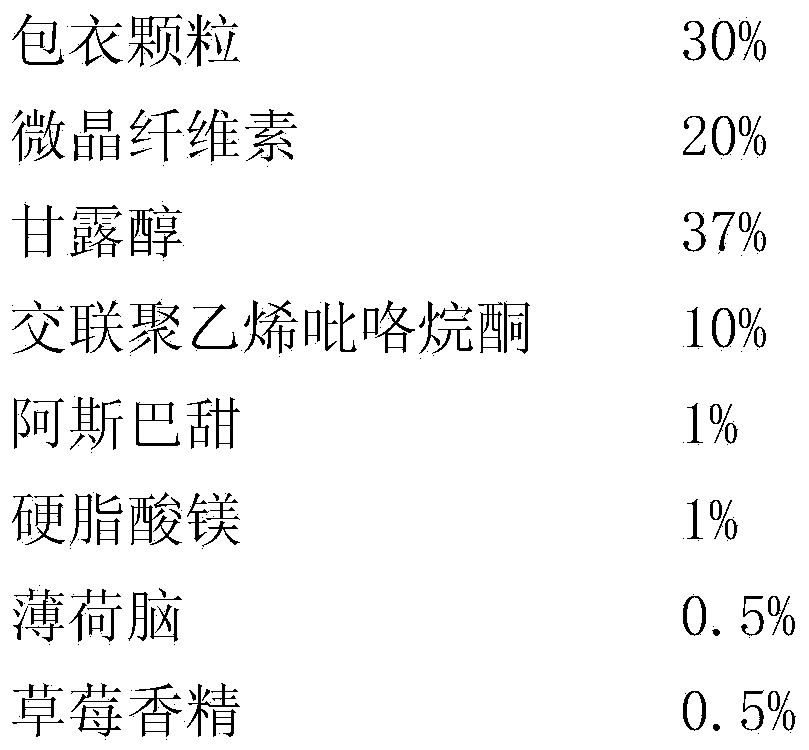

[0031] Mix fluoxetine hydrochloride (mass ratio, the same as 30% in the following examples), microcrystalline cellulose (60%), and low-substituted hydroxypropyl cellulose (10%), add wetting agent purified water to make a soft material, Pass through a 0.5mm aperture sieve, extrude through a screw extruder to make strips, set rounding equipment to spheronize to obtain pellets, and dry at 55°C to obtain drug-containing pellet cores.

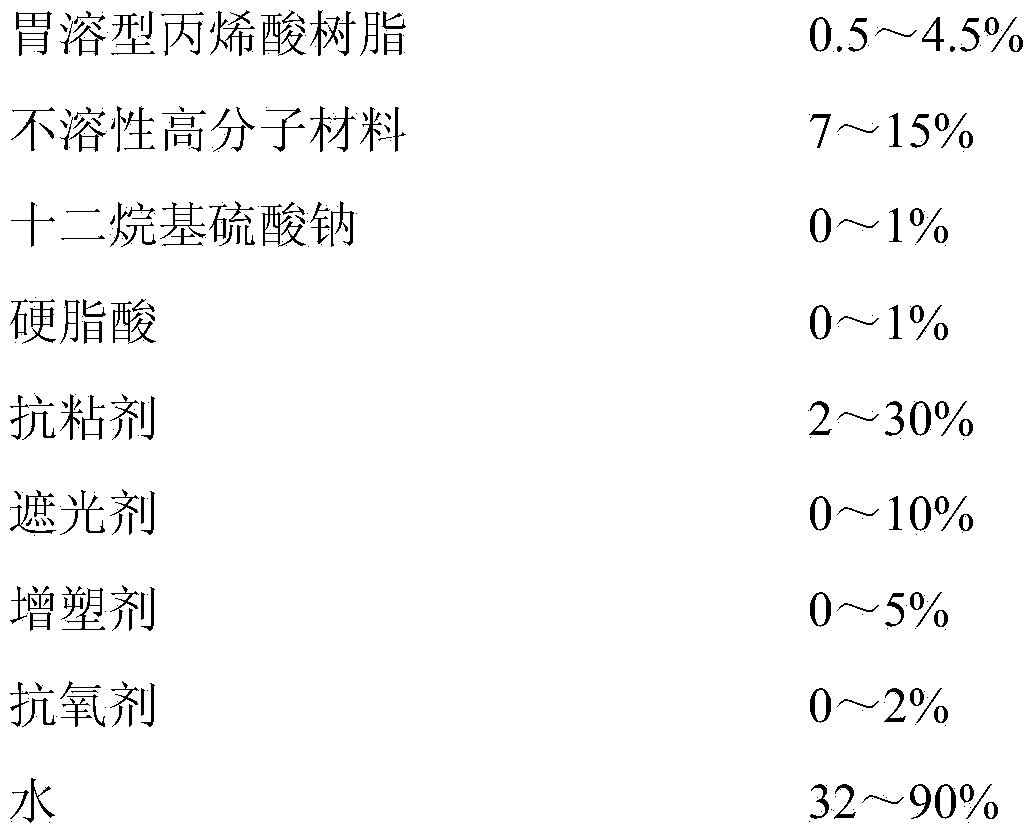

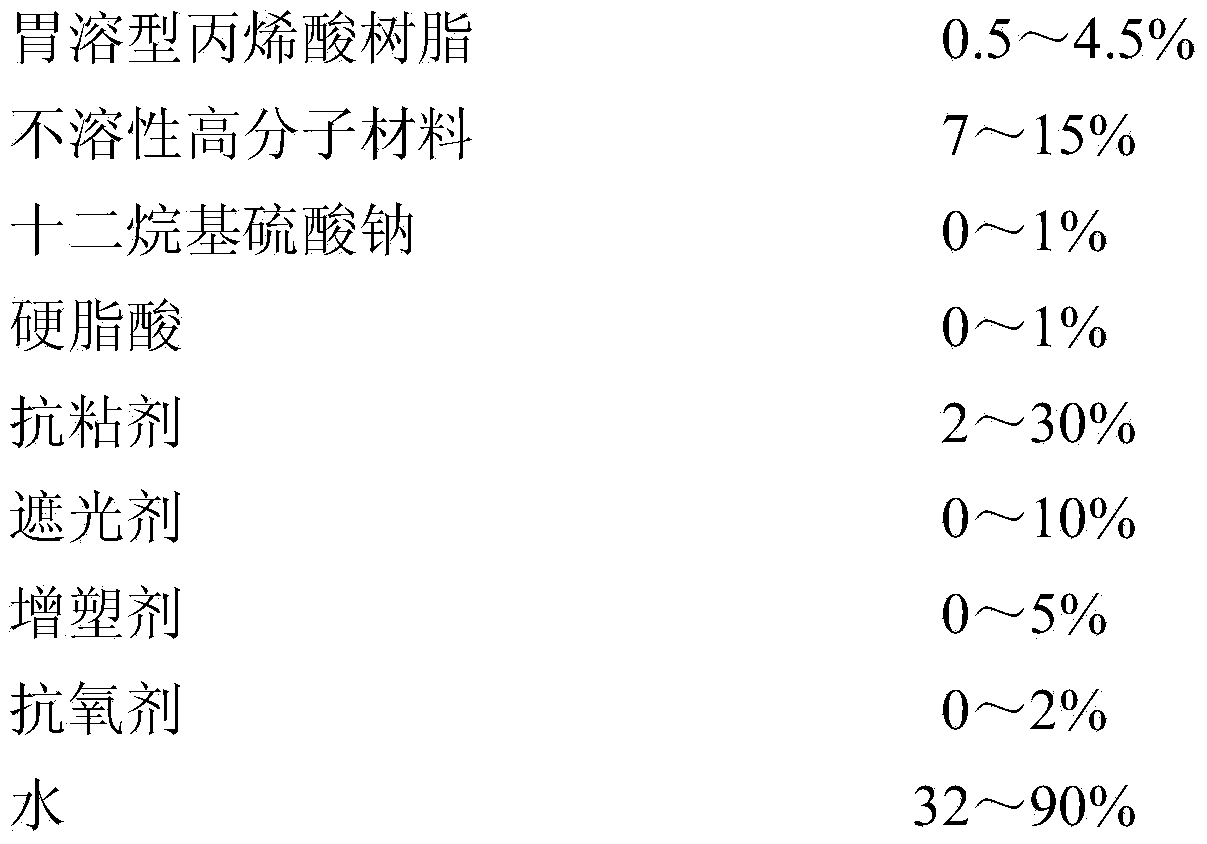

[0032] Prepare a mixed aqueous dispersion coating solution containing stomach-soluble and insoluble materials: Sodium lauryl sulfate (1.5g) is dissolved in 300g pure water, add stearic acid (2.25g) to fully disperse, then add Eudragit EPO (15g ) continuously stirred to make a translucent colloidal solution; mix evenly with Eudragit NE30D (283.3g, solid content 85g) water dispersion, then add triethyl citrate (2.25g), talcum powder (85g), add pure water To 1000g, homogenize at 10000rpm high-speed shearing, fully stir and mix evenly. Stir continuousl...

Embodiment 2

[0037] Get 40-50 order microcrystalline cellulose blank ball core, take 3% hypromellose aqueous solution as binding agent, fluoxetine hydrochloride (60%), microcrystalline cellulose (38.5%) and micropowder silica gel ( 1.5%) of the mixture is powder-layered and drug-coated to obtain 40% drug-containing pellets.

[0038] Adjust the ratio of Eudragit EPO and NE30D to 1:9, prepare the aqueous dispersion coating solution containing stomach-soluble and insoluble materials according to Example 1, and perform bottom-spray fluidized coating on the core containing pills.

[0039] When the coating weight increased by 5%, the drug dissolution of the coated pellets in water in 5 minutes was 3.4%; the dissolution in 0.1mol / L hydrochloric acid aqueous solution was 55%, and the dissolution was complete in 45 minutes.

[0040] When the coating weight increased by 8%, the drug dissolution of the coated pellets in water was 1.7% in 10 minutes; the dissolution in 0.1mol / L hydrochloric acid aqueo...

Embodiment 3

[0042] Get micronized fexofenadine hydrochloride (60%), microcrystalline cellulose (28%) and micronized silica gel (2%) to put in fluidized bed, use 10% Eudragit EPO aqueous dispersion as binder system granules to obtain granules containing 60% of the drug.

[0043] Prepare a mixed aqueous dispersion coating liquid containing stomach-soluble and insoluble materials: Sodium lauryl sulfate (2g) is dissolved in 300g pure water, add stearic acid (3g) to fully disperse, then add Eudragit EPO (20g) to continue Stir to make a translucent colloidal solution; add talcum powder (80g), titanium dioxide (30g), antioxidant BHT (0.3g), triethyl citrate (4g), and mix with Mix the colloidal solution of stomach-soluble materials, then mix with Eudragit NE30D (267g, solid content 80g) aqueous dispersion, and finally add pure water to 1000g, mix well and get ready. Stir continuously during the coating process.

[0044] The drug-containing granules are subjected to bottom spray fluidized coatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap