Anchor rod reinforcing steel bar in 400-MPa level and production method thereof

A production method and steel bar technology, applied in the direction of metal rolling, etc., can solve the problems of base circle size and deviation, transverse rib size requirement and transverse rib spacing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

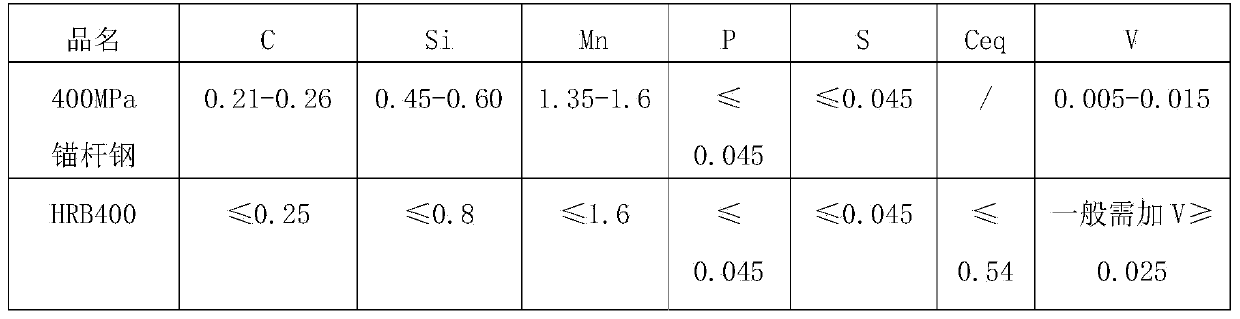

[0032] 1. Design reasonable process control parameters and compare with HRB400, see Table 1 and 2.

[0033] 1) Composition is designed by mass percentage:

[0034] Table 1 Ingredient Requirements%

[0035]

[0036] According to the data in the above table: (1) The carbon content of the 400MPa anchor bar is higher than the requirement of HRB400; (2) Adding V and lowering does not require controlled cold rolling. If HRB400 does not add V, Nb, Ti or controlled cold rolling, the strength cannot be achieved. fulfil requirements.

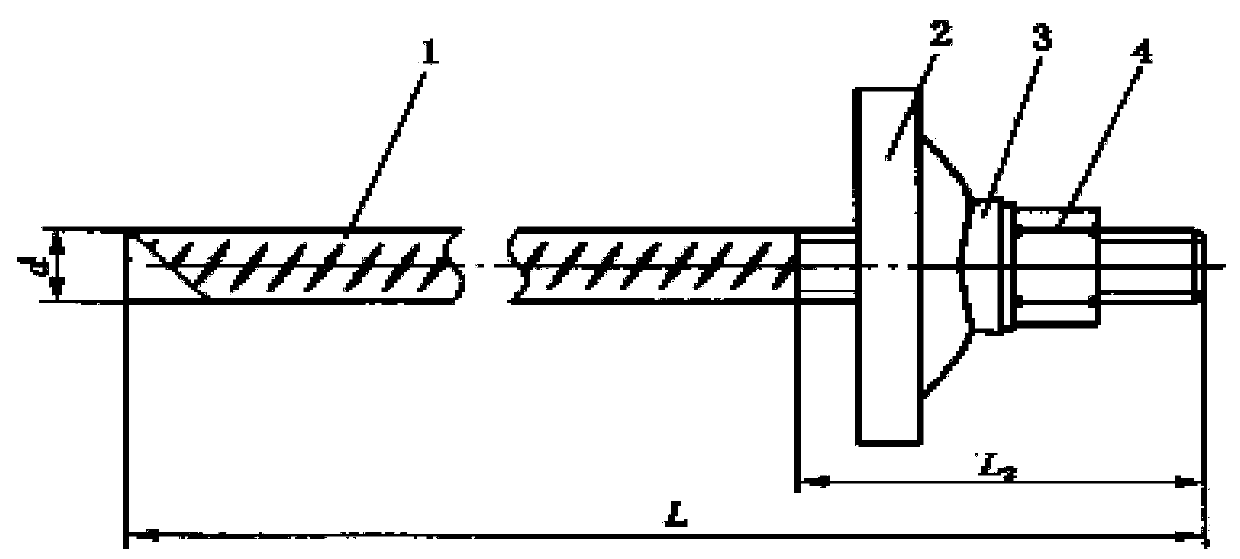

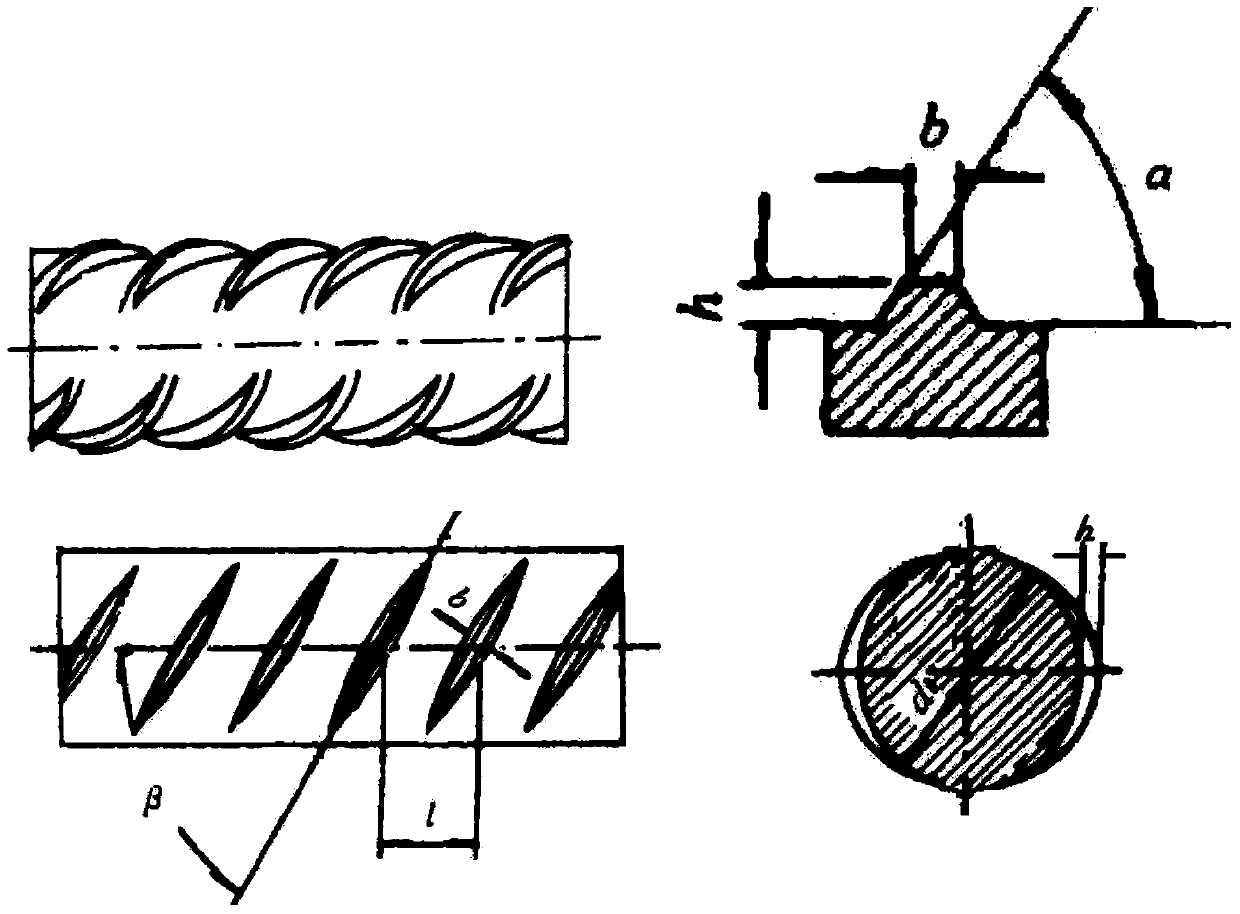

[0037] 2) Appearance size design

[0038] Crescent ribs are used, the angle α between the side of the transverse rib and the surface of the steel bar is designed to be 51°, and the angle β between the transverse rib and the axis of the steel bar is designed to be 55°. The shape is shown in figure 2 , size and allowable deviation, see Table 2.

[0039] Table 2 Dimensions and allowable deviation

[0040]

[0041] According to the data in the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com