Lifting welding spattering falling preventing device

A technology of anti-falling and cylindrical barrels, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large welding sparks, etc., and achieve good practical application value and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

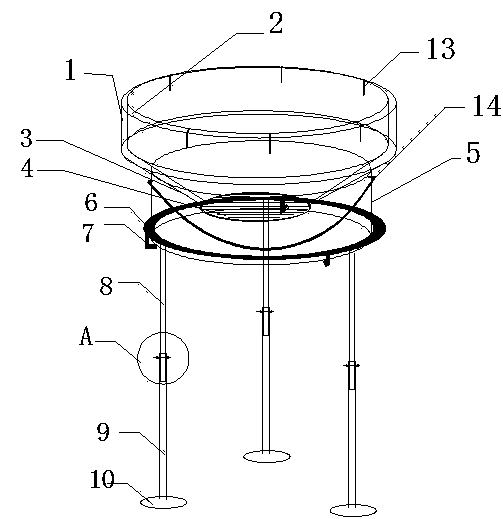

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

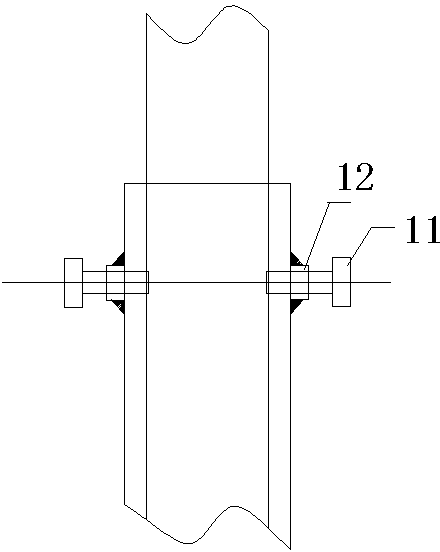

[0021] Such as figure 1 , figure 2 As shown, the anti-falling device for welding spatter can be raised and lowered, including:

[0022] The upper anti-falling device comprises an upper hollow cylinder 1, a hollow cone 3 connected to the upper hollow cylinder 1 and a lower cylindrical barrel 5, the bottom of the hollow cone 3 is provided with a strip net 4, and the hollow cone 3 The lower part is inserted into the lower cylinder barrel 5, and an asbestos layer 2 is laid in the upper hollow cylinder 1 and the hollow cone 3, and the asbestos layer 2 is fixed on the upper hollow cylinder 1 by wire clips 13 to prevent the asbestos layer 2 from Complete laying can ensure that all spatter can fall on the asbestos layer 2. In addition, the asbestos layer 2 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com