Novel manual compressor for binding inflatable dumper

An inflatable, shock absorber technology, applied in the field of shock-absorbing spring compression, can solve the problems of not popularizing, time-consuming, labor-intensive, and labor-intensive, and achieve the effects of reducing labor, simple operation, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

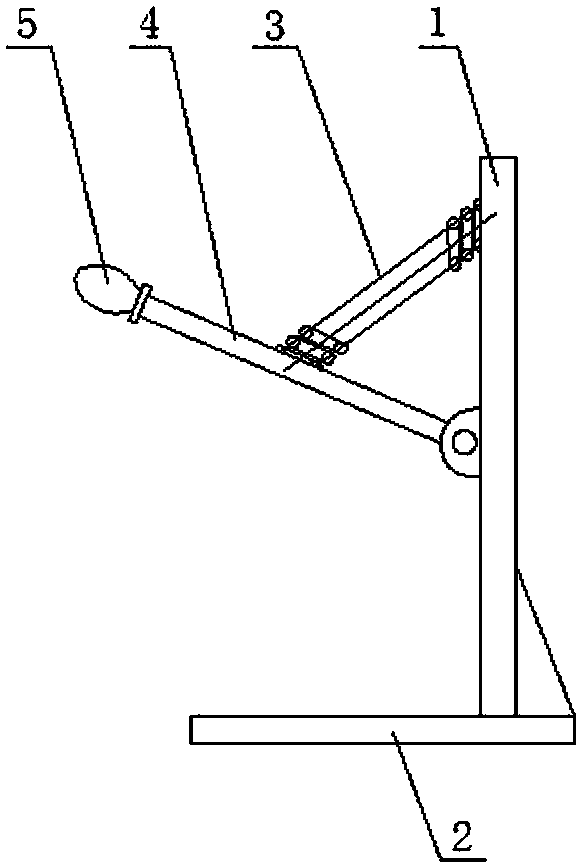

[0011] Such as figure 1 As shown, a new type of manual compressor for binding pneumatic shock absorbers includes a column 1, a workbench 2, a tension spring 3 and a pressure plate 4. The column 1 is perpendicular to the workbench 2 and is fixedly installed on the workbench 2, one end of the pressing plate 4 is hinged on the column 1, and the other end of the pressing plate 4 is provided with a handle 5, and the handle 5 is in an oval shape. Such as figure 1 As shown, one end of the tension spring 3 is fixedly installed on the pressure plate 4, and the other end of the tension spring 3 is fixedly installed on the column 1, and the connection between the tension spring 3 and the column 1 is higher than the height of the workbench 2 than the pressure plate 4 At the hinge with the column 1, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com