A device for pasture high-density compression molding and a method for adjusting weight during compression

A compression molding, high-density technology, used in electrical program control, program control in sequence/logic controllers, packaging, etc., can solve the problem of difficult to control the weight of large straw bales, achieve convenient weight adjustment, avoid bulging, Inconvenience prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

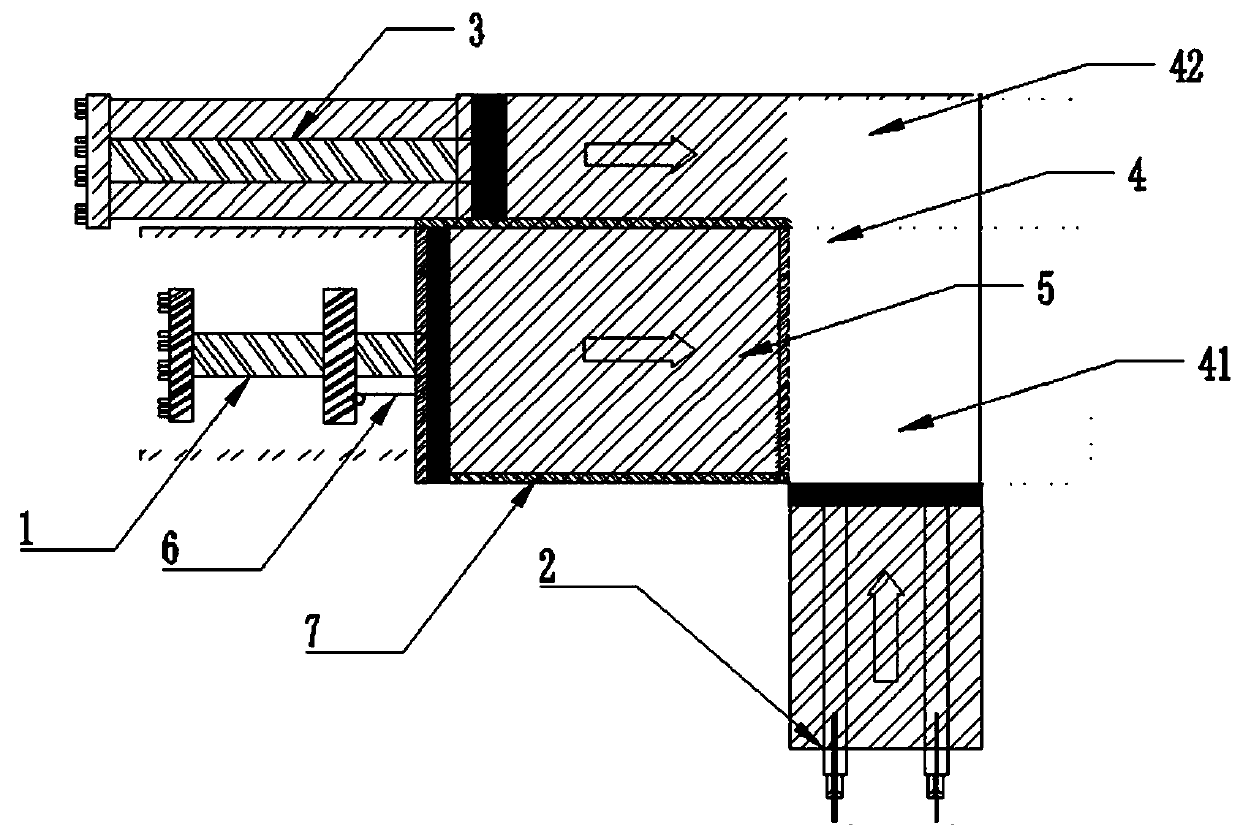

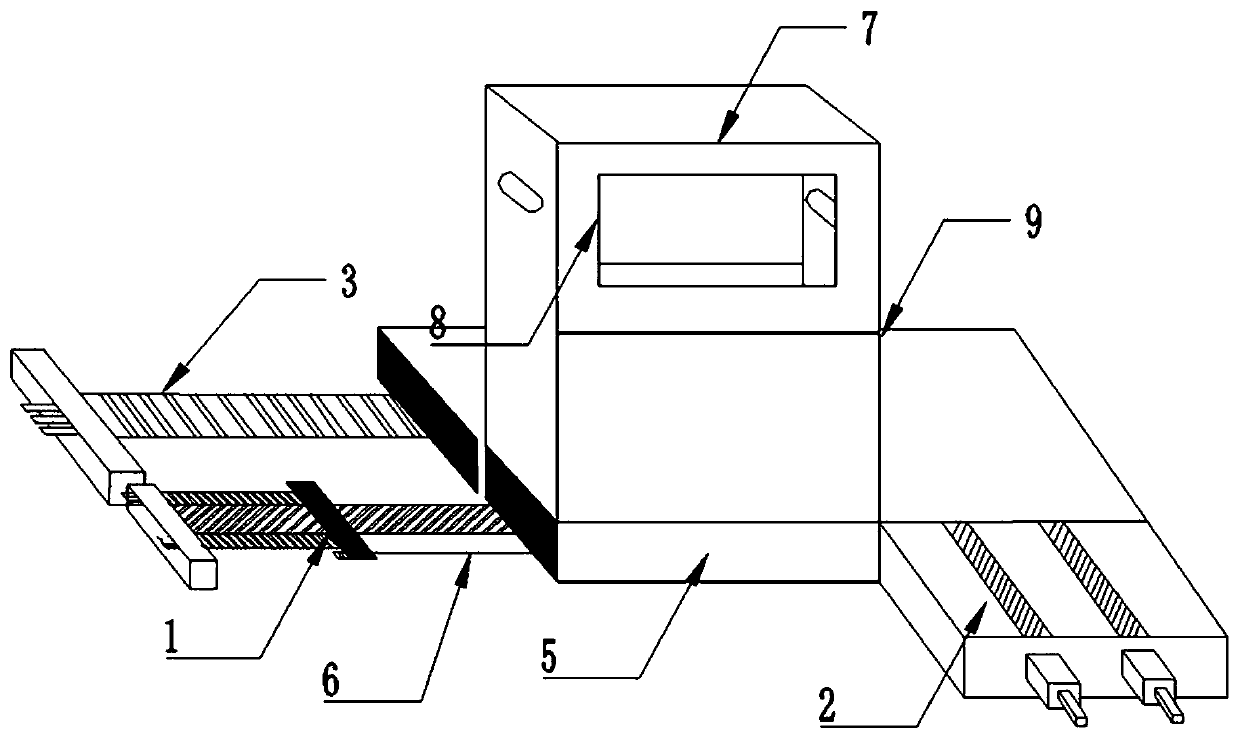

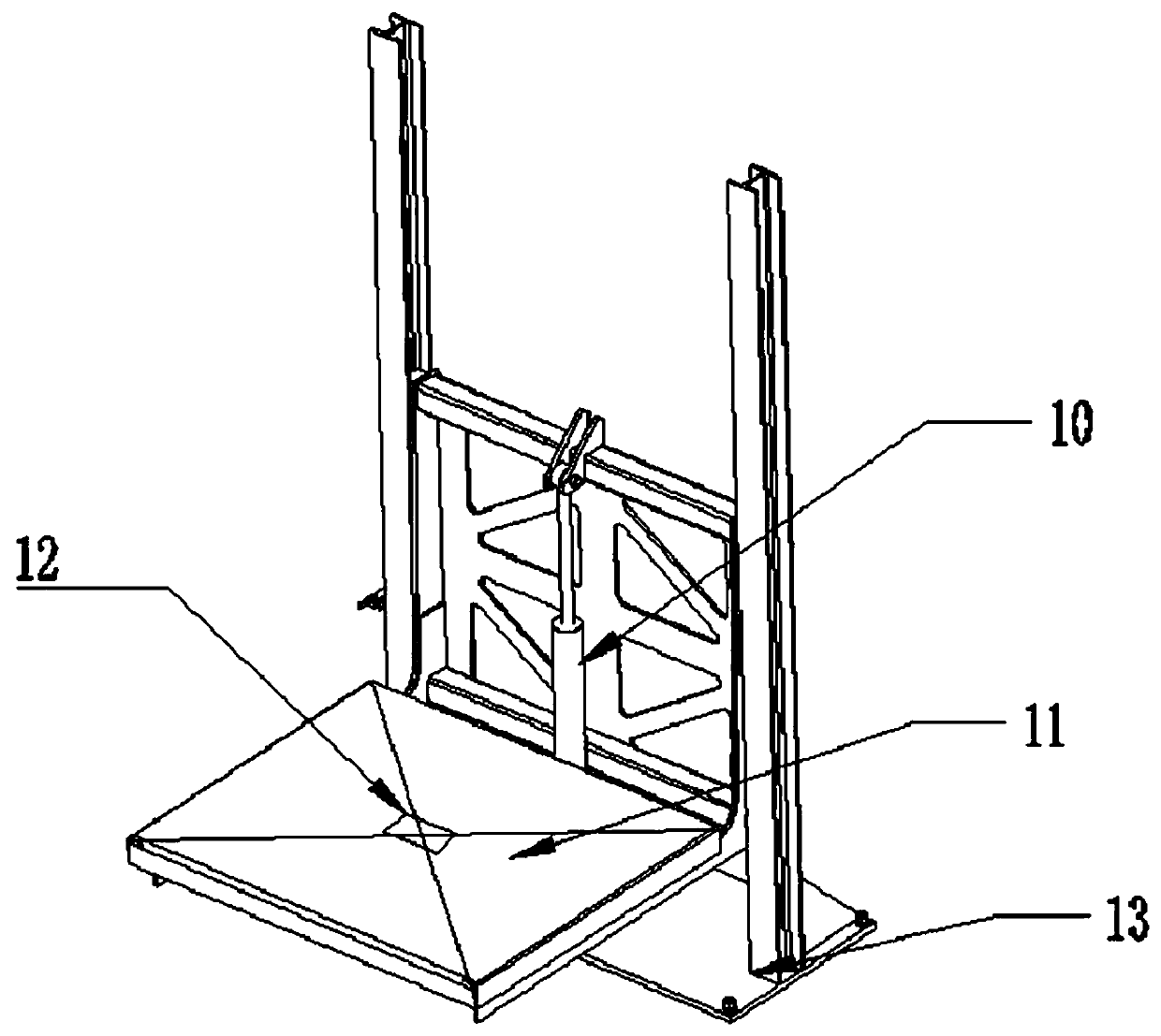

[0035] like Figure 5 As shown, the forage pre-compression chamber 5 is generally the first-stage compression type chamber in the multi-stage compression process, after multiple pushes by the first-stage compression cylinder 1 (the forage material volume pushed each time is the same, and the stroke is a ), push the pasture material to the second compression molding bin 41, such as figure 1 As shown, the second-stage compression cylinder 2 then performs the second-stage compression process, and after the forage material is compressed to the third compression molding chamber 42 corresponding to the third-stage compression cylinder 3, the third-stage compression cylinder 3 starts to perform the third-stage compression process. Compression process. After the three compressions are completed, the formed large bales are pushed out to complete a compression cycle. During the first-stage compression process, the first-stage compression cylinder 1 is equipped with a rope displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com