Device group for replacing malfunctioning motor part of aerial work tower crane

It is a technology for failures and high-altitude operations. It is applied to cranes and other directions. It can solve the problems of wire ropes falling off at high altitudes, easy tripping of wire ropes, and low safety factor, and achieves the effects of stable operation, improved work efficiency, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

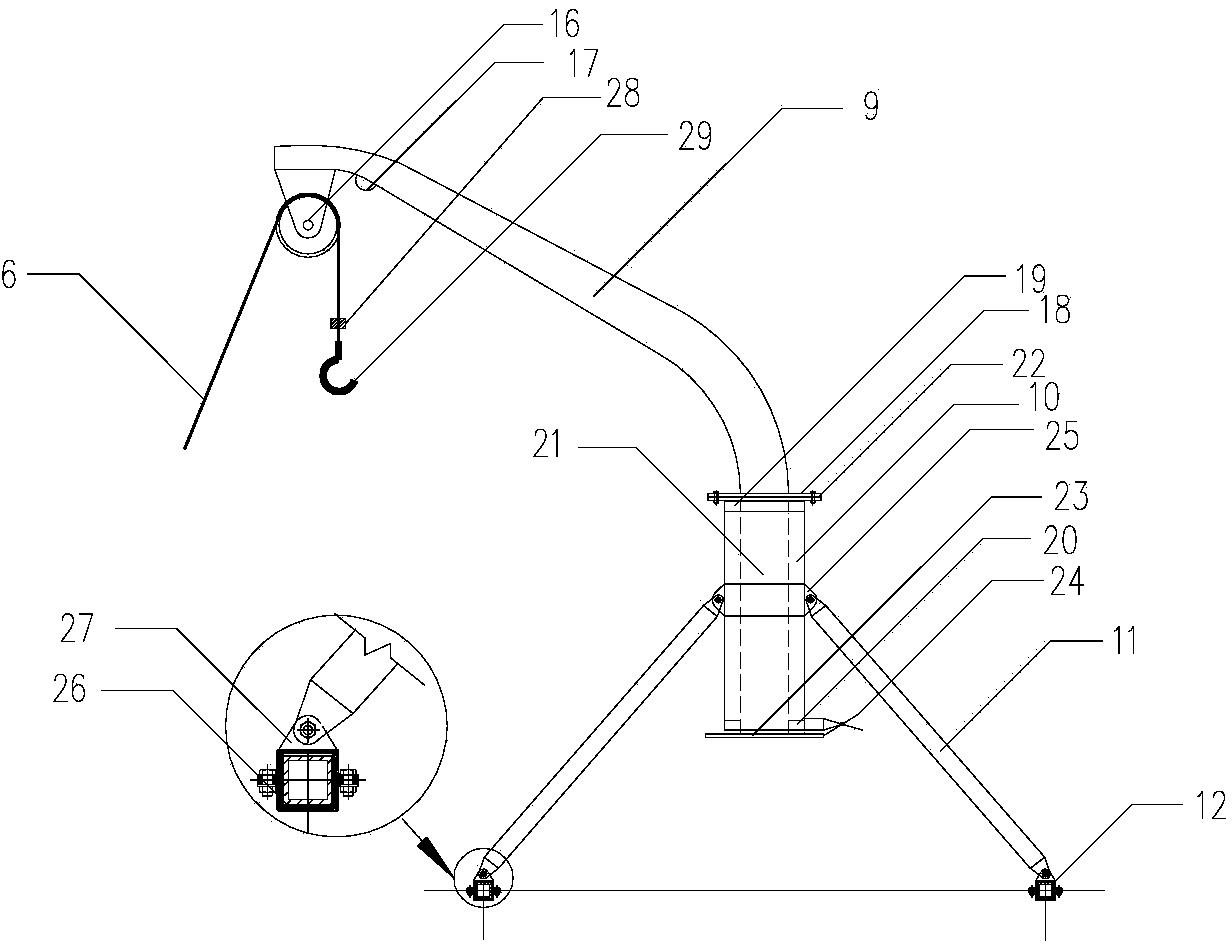

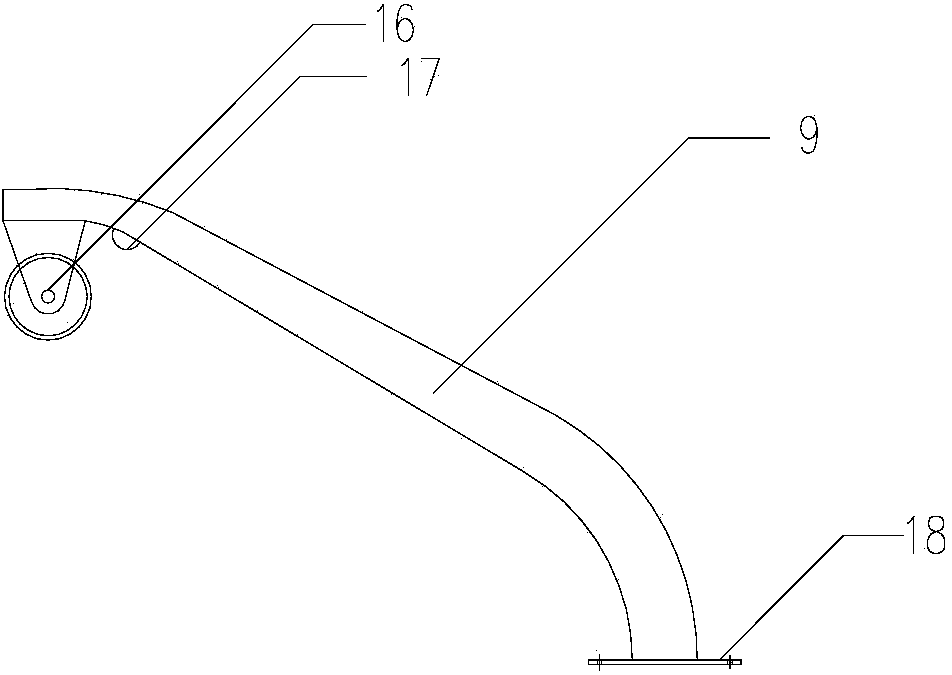

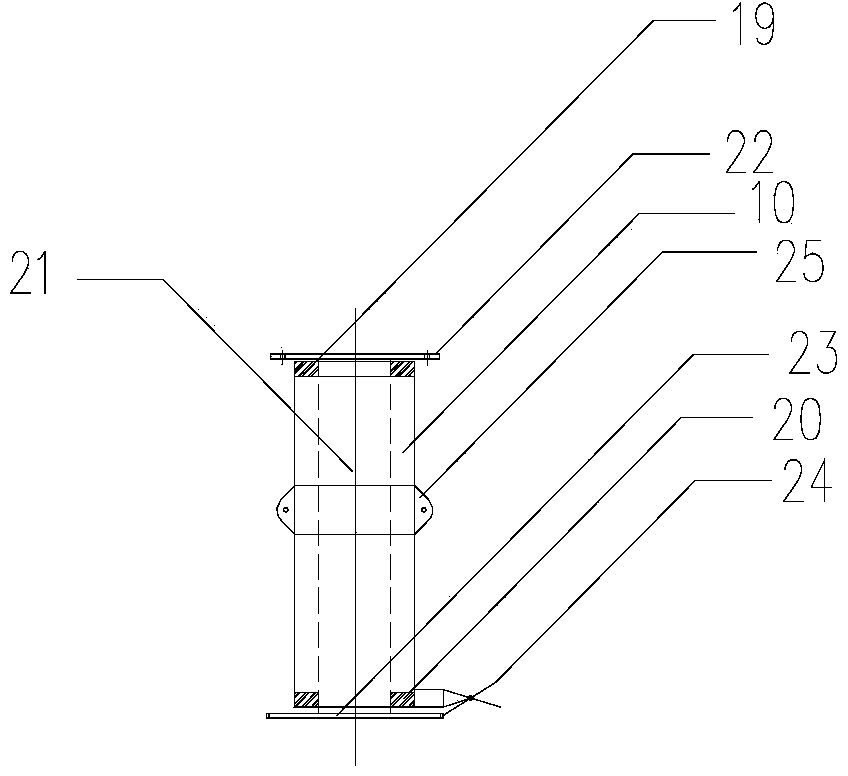

[0022] The structure of the equipment group for replacing the faulty motor parts of the high-altitude operation tower crane according to the present invention will be described in conjunction with the accompanying drawings.

[0023] 1. Description of the components that make up the equipment group

[0024] Such as figure 1 , 2 , 3, the present invention is used to replace the equipment set of the faulty motor parts of the aerial work tower crane, the equipment set includes a triangular bracket 2, and the triangular bracket 2 is fixed on the balance arm of the tower crane. One side of the tower crane is fixed with a hoist 1, and the hoist 1 includes a motor 3, a reducer 4, a rope winding part 5, a steel wire rope 6, a base 7, and a counterweight 8, and the hoist is fixed on the ground through the counterweight 8. The hoist 1 provides power, and the triangular support 2 is used as an auxiliary support facility, which can realize hoisting the motor of the tower crane to the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com