A diode immersion tin device and its use method

A diode and immersion tin technology, which is applied in the field of diode immersion tin devices, can solve the problems of low work efficiency, uneven tin plating, and affecting the mass production of diodes, etc., and achieve the effect of simple structure, uniform immersion tin, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

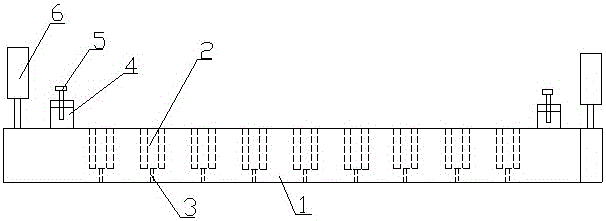

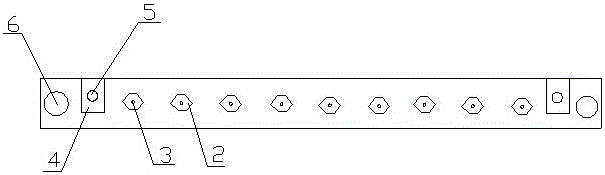

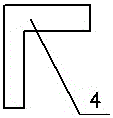

[0024] refer to Figure 1 to Figure 4 , the diode immersion tin device of the present invention comprises a tin immersion plate 1 and a fixing plate 7 with 9 tin immersion holes, the upper part of the immersion tin hole is made as a hexagonal hole 2 matching the diode head, and the lower part of the immersion tin hole is made as a The lead hole 3 matched with the diode lead wire is used to put the diode into the tin dipping hole, and a clamping device is installed on both sides of the dipping tin plate 1, and the clamping device includes an inverted tin plate fixed on the tin dipping plate 1 The buckle block 4 and the bolt 5 located on the undercut plate 4, the bolt 5 cooperates with the screw hole on the undercut block 4, the bolt 5 can spiral down to fix the fixed plate 7, and the fixed plate 7 has a U-shaped Mouth 8.

[0025] Among the present invention, the material of the dipped tin plate 1 and the fixed plate 7 is steel, and the surfaces of the dipped tin plate 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com