An automatic manipulator

An automatic operation and manipulator technology, applied in manipulators, program-controlled manipulators, tin feeding devices, etc., can solve the problems of high physical hazards, low production efficiency, and high labor intensity, and achieve low pass rate, heavy workload, and high welding quality. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

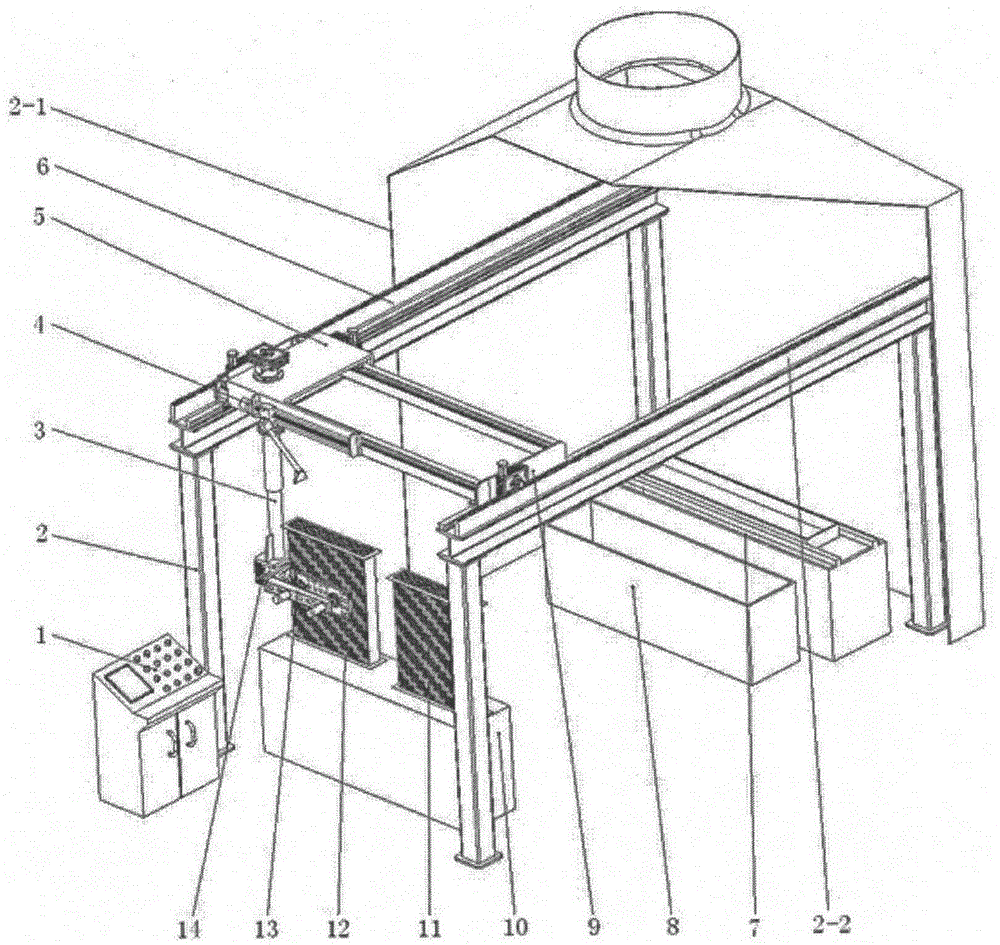

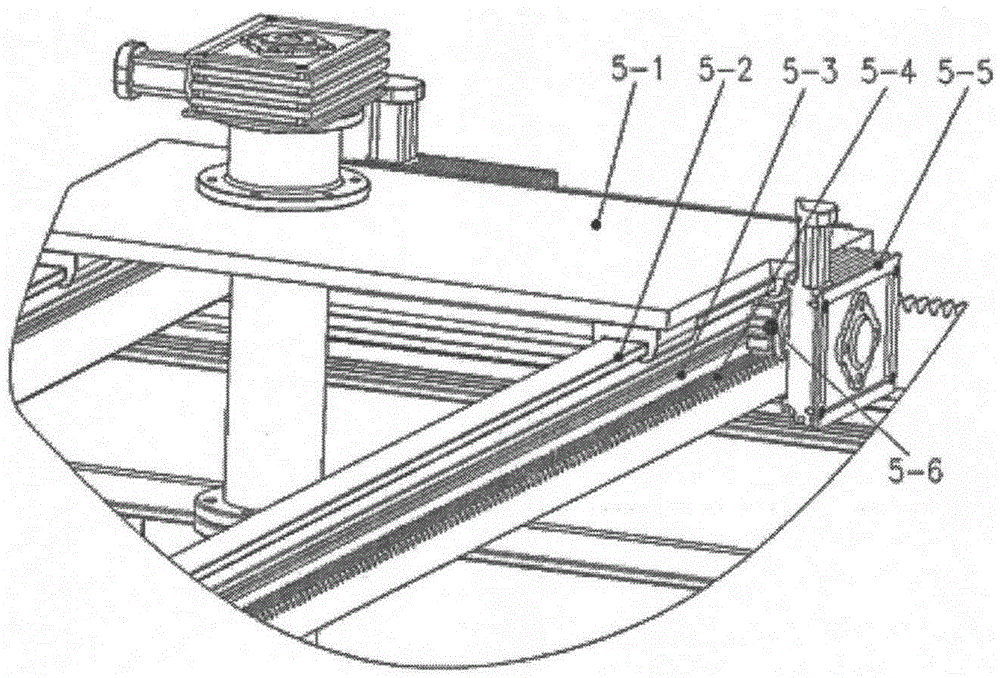

[0033] like Figure 1-8 Shown, for a kind of automatic operation manipulator provided by the present invention, comprise the main door frame 2 that the door frame one 2-1 of parallel arrangement, door frame two 2-2 constitute, the main door frame 2 is provided with can be installed on the door frame one 2-1, the Y-axis moving mechanism 9 that moves in the direction of the door frame two 2-2, the Y-axis moving mechanism 9 is connected with the door frame one 2-1 and the door frame two 2-2; the Y-axis moving mechanism 9 is provided with a movable The X-axis moving mechanism 5 that moves on the Y-axis moving mechanism 9 is connected to the turning mechanism 14 through the lifting shaft mechanism 3 , and the turning mechanism 14 is provided with a clamping arm 13 .

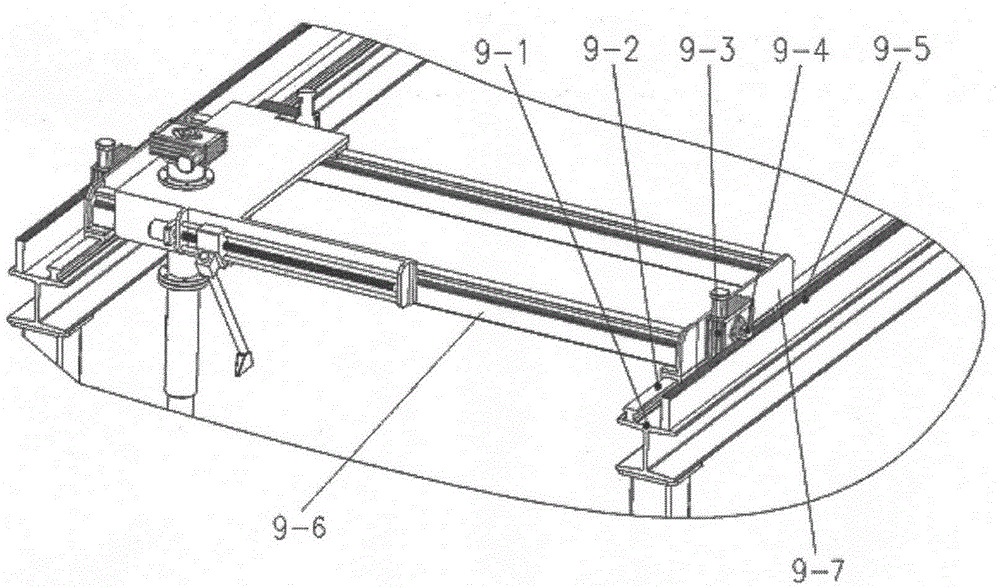

[0034] like figure 2 As shown, the Y-axis moving mechanism 9 includes two Y-axis moving beams 9-1 respectively arranged on the tops of the first door frame 2-1 and the second door frame 2-2, and a pair of Y-axis mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com