Joint suitable for connection between string truss stay bar and multiple cables

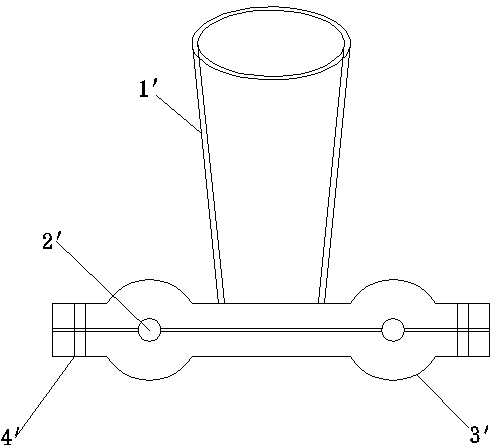

A string truss and node technology is applied to the node field where the string truss struts are connected with multiple cables to avoid uncertainty and excessive residual stress, clear force transmission paths, and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

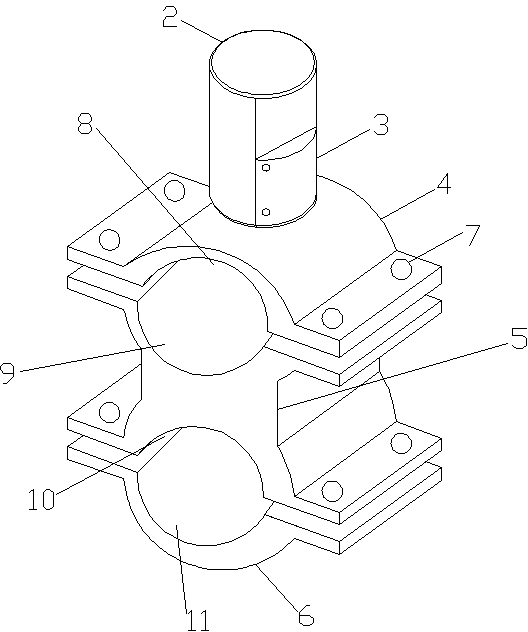

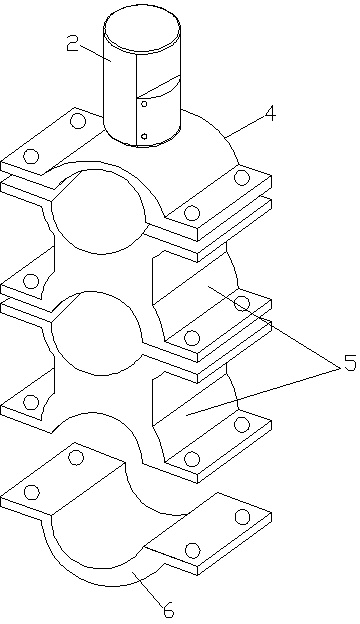

[0016] Reference attached figure 2 , a node suitable for connecting string truss struts with multiple cables, comprising a cable connector, a vertically arranged strut connector is arranged on the top of the cable connector, and the cable connector includes an upper connector 4 and the lower connecting piece 6, at least one middle connecting piece 5 is installed between the upper connecting piece 4 and the lower connecting piece 6. The top of the middle connector 5 is provided with a downwardly concave upper arc groove 9, the bottom of the middle connector 5 is provided with an upwardly concave lower arc groove 10, and the upper connector 4 is provided with an upward protrusion and an upper circle. The arc groove 9 cooperates and butts to form the upper arc groove 8 of the upper cable hole, and the lower connector 6 is provided with a lower arc groove 11 that protrudes downward and cooperates with the lower arc groove 10 to form the lower cable hole; the upper arc groove 9 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com