Hard rock tunnel boring machine

A technology of tunnel boring machine and boring machine, which is applied in the direction of tunnel, mining equipment, earth-moving drilling and mining, etc., can solve the problems of long structure length and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

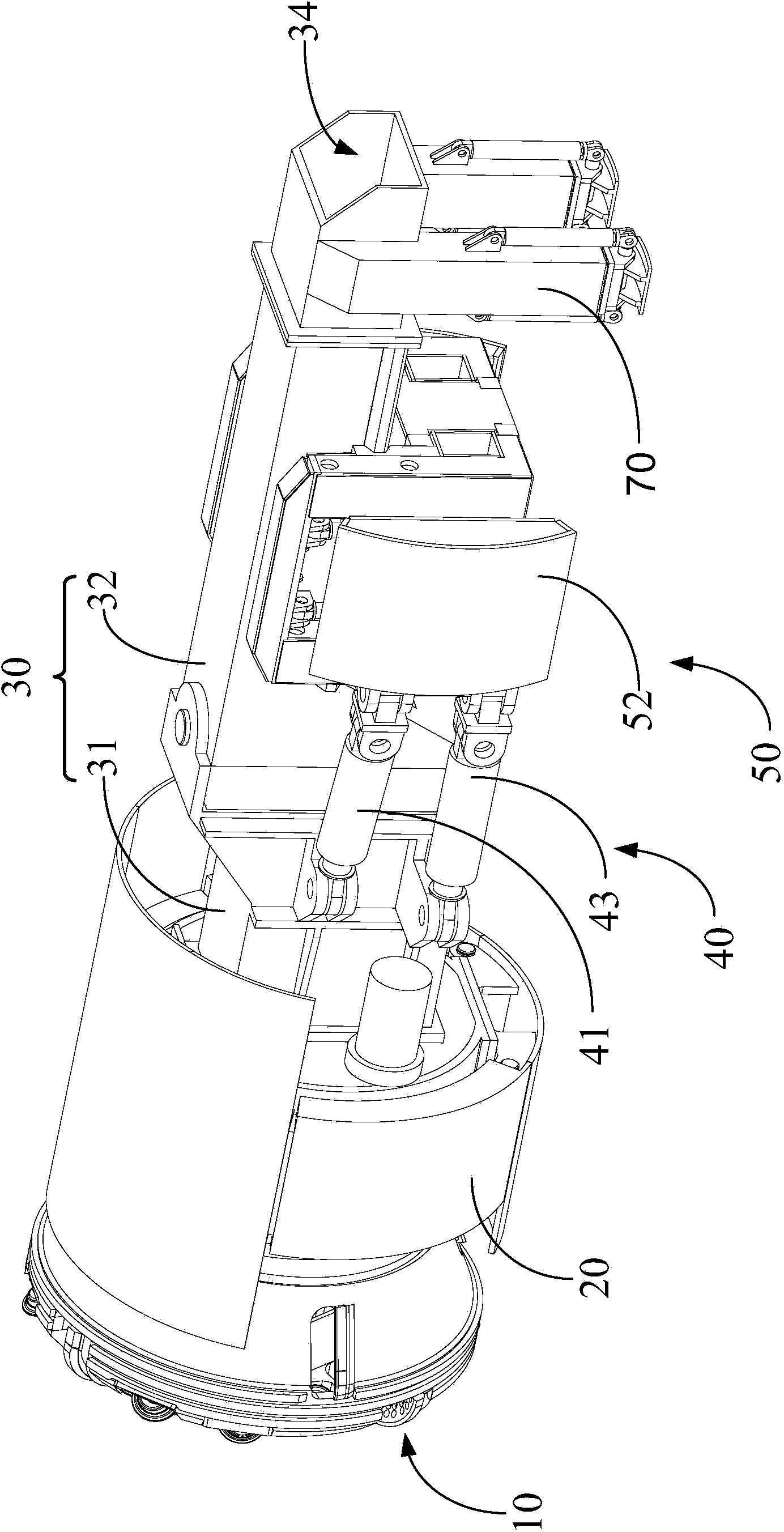

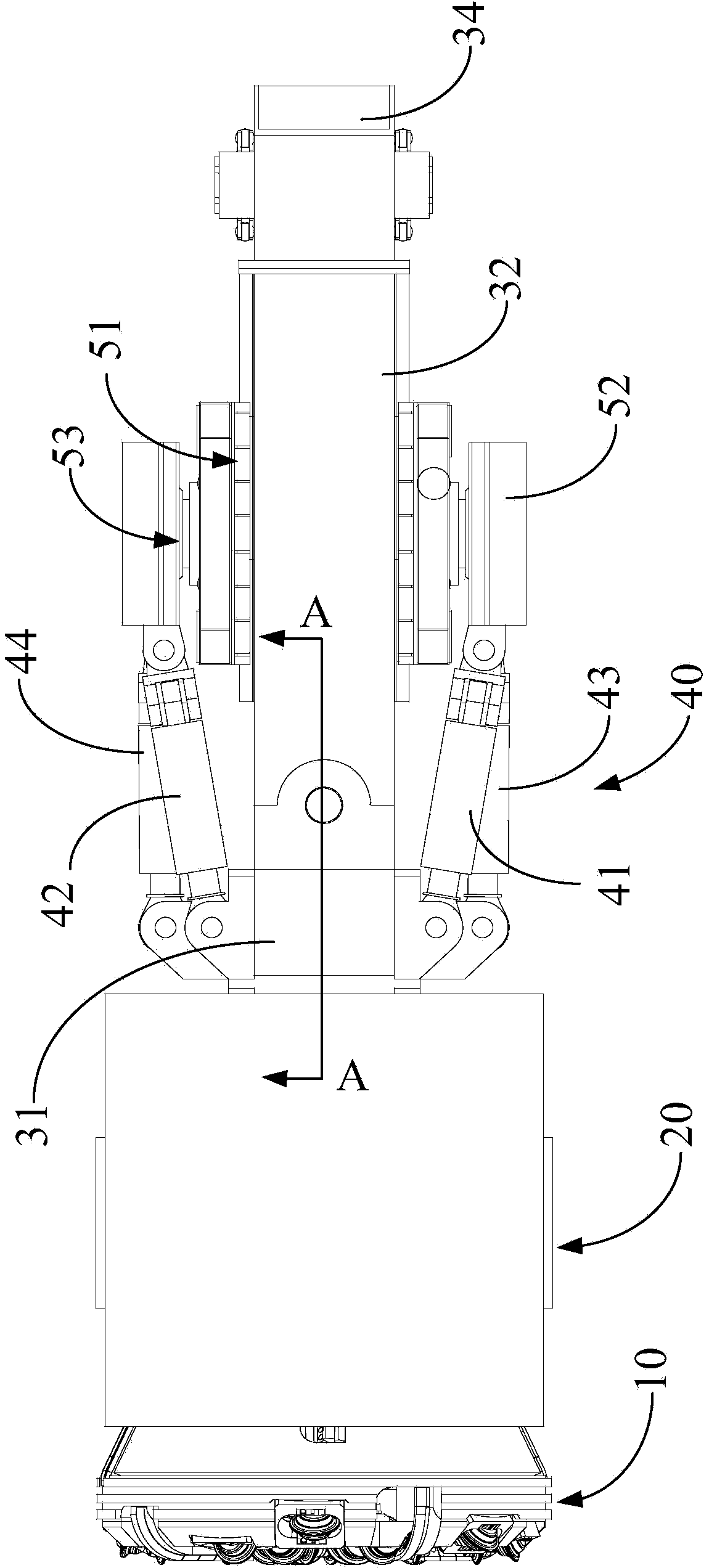

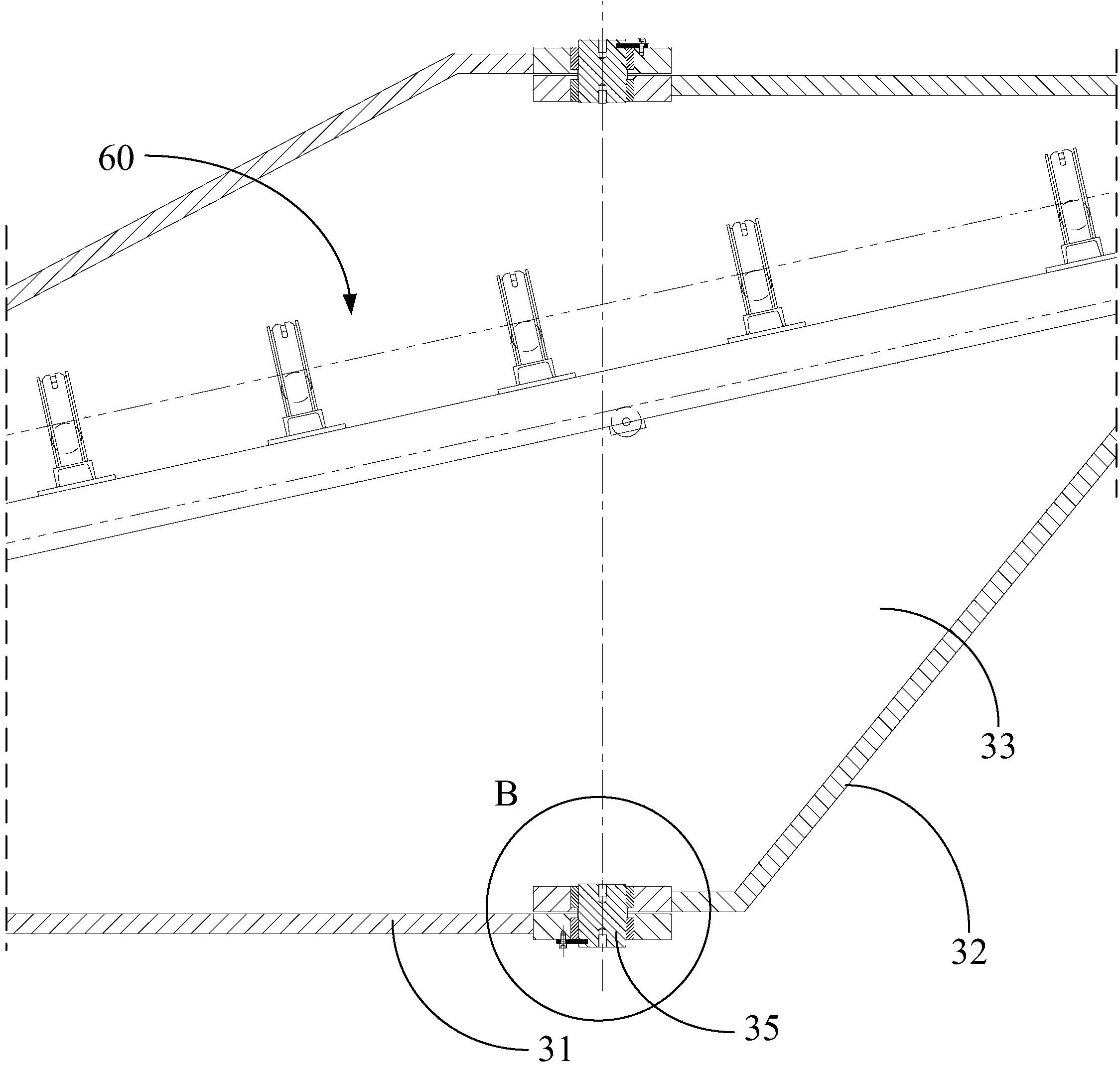

[0023] As shown in the figure, the hard rock tunnel boring machine proposed by the present invention includes a cutter head 10 , a drive system 20 , a main beam 30 and a propulsion support system. The main beam 30 includes a front main beam 31 and a rear main beam 32 . The hard rock tunnel boring machine of the present invention and its individual components will be described in detail below.

[0024] like figure 1 and figure 2 As shown, the cutter head 10 can cut cuttings, and according to the cut rock formation and production capacity, corresponding cutters, such as hobs, can be installed on the cutter head 10 . The cutterhead 10 is mounted to the front end of the drive system 20 via a cutterhead support device.

[0025] The drive system 20 generates a turning moment to drive the cutter head 10 to rotate, thereby realizing rock breaking by the hob. As shown in the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap