Black smoke catcher used for diesel engine

A technology of black smoke traps and traps, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor regeneration reliability, high regeneration costs, and complicated devices, and achieve compact structure and reduce exhaust Back pressure, easy cropping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

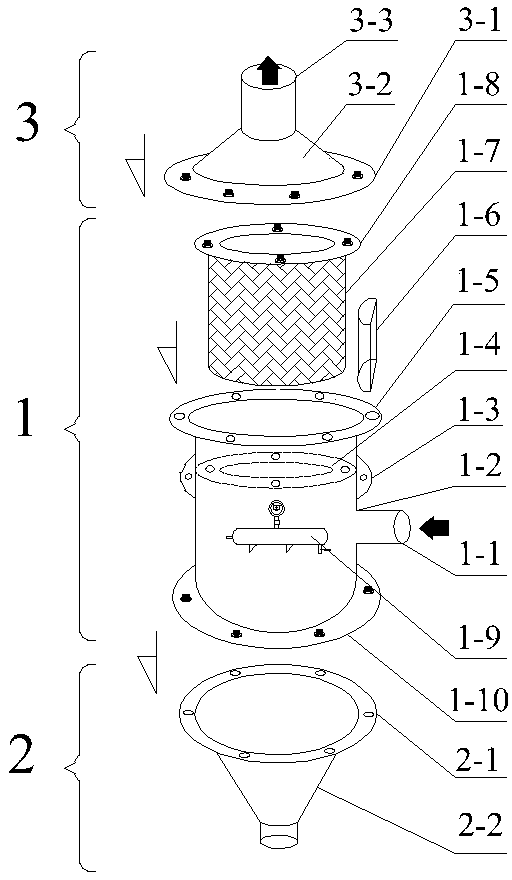

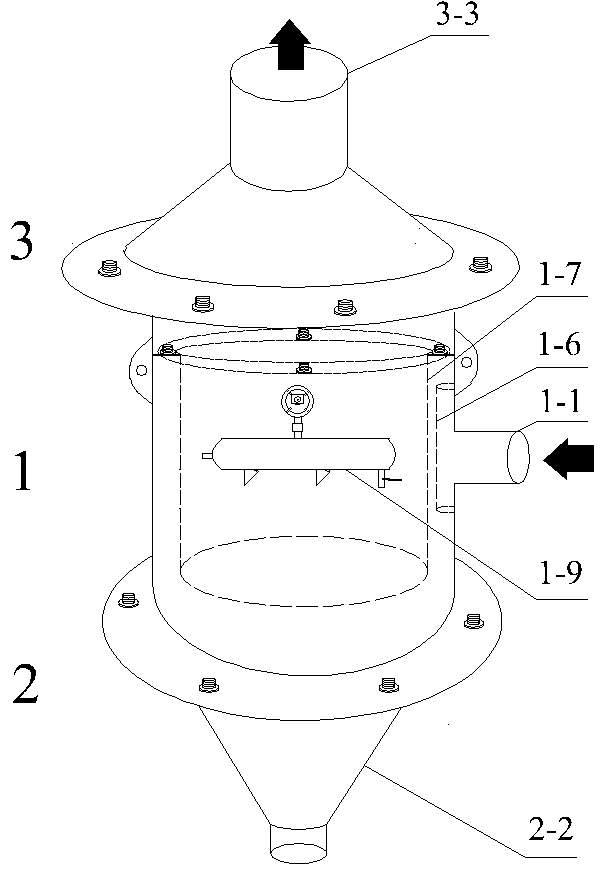

[0015] As above figure 1 , figure 2 As shown, the present invention provides a diesel engine black smoke trap, which consists of a trap cylinder body 1 , black smoke collection end 2 and trap outlet 3 It consists of three parts. Among them, the main body of the collector cylinder 1 Including: air inlet 1-1, cylinder 1-2, fixed ear 1-3, cylinder inner wall flange 1-4, cylinder upper edge flange 1-5, air inlet baffle 1-6, filter element 1-7, filter element flange 1-8, electromagnetic pulse pneumatic control valve 1-9 and cylinder lower edge flange 1-10, wherein electromagnetic pulse pneumatic control valve 1-9 is a collection of electromagnetic valve, gas box, gas The assembly of the valve and the open-hole bomb gas pipe is commercially available; the black smoke collection end 2 Including: base flange 2-1 and black smoke collection port 2-2; collector gas outlet 3 Including: air outlet flange 3-1, air outlet end cover 3-2 and air outlet connecting pipe 3-3.

[0016] Th...

Embodiment 2

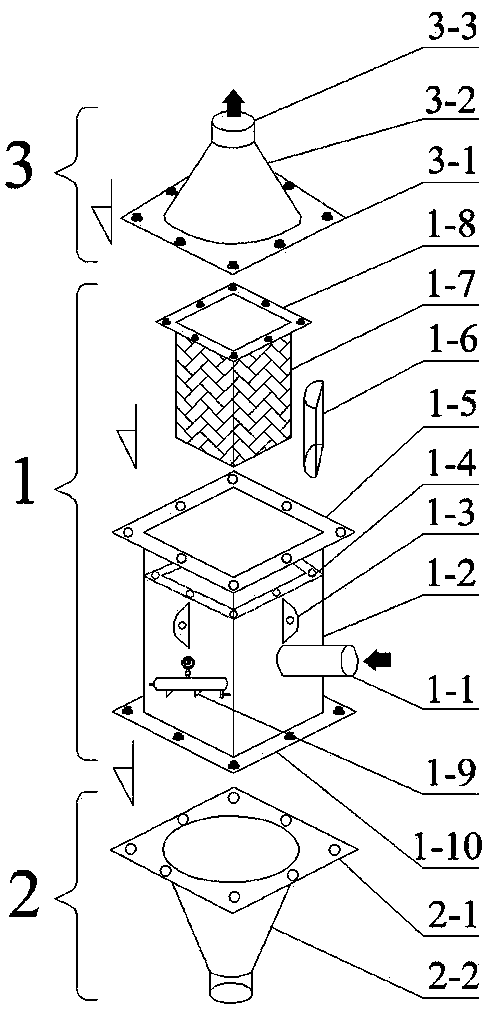

[0019] image 3 , Figure 4 It is a structural schematic diagram of Embodiment 2 of the present invention. Except adopting square filter element 1-7 and square casing, its implementation method is basically consistent with embodiment 1. The square shell is used to facilitate the installation and replacement of the black smoke trap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com