Drive device for the road wheels of a vehicle

A driving mechanism and wheel technology, applied in the direction of transmission, mechanical equipment, transmission parts, etc., can solve the problem of large agitation loss and achieve good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

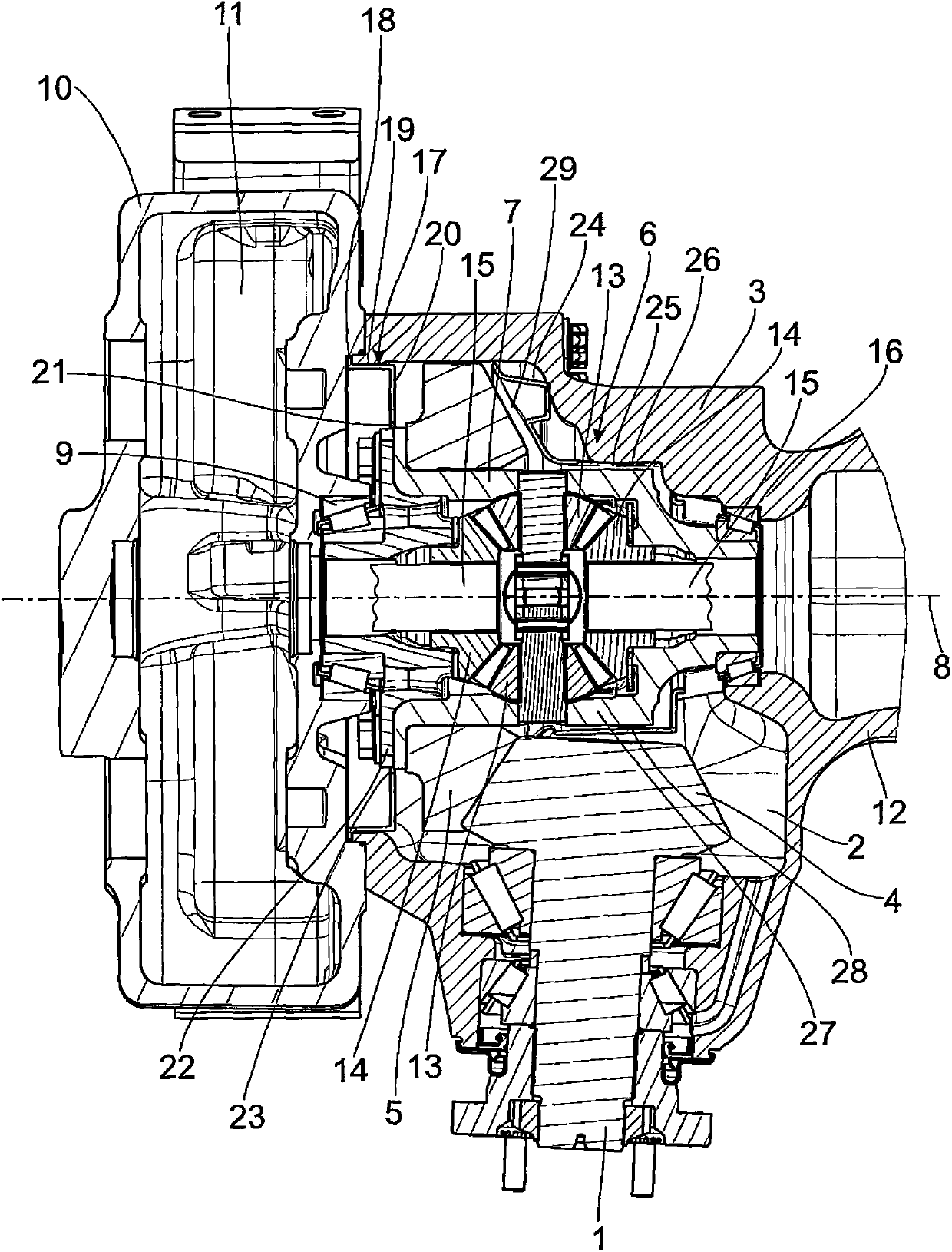

[0052] A drive shaft 1 , which is rotatable by an engine of the vehicle, is inserted approximately horizontally into a housing interior 2 of a housing 3 .

[0053] At its end protruding into the housing 3 , the drive shaft 1 has a drive gear 4 designed as a bevel gear, which meshes with a ring gear 5 of the differential unit 6 , which is also designed as a bevel gear.

[0054] The ring gear 5 is fixedly connected to the differential housing 7 and is rotatably mounted by means of the differential housing on two differential bearings 9 , 16 about an axis of rotation 8 extending at right angles to the axis of rotation of the drive shaft 1 superior.

[0055] The first differential bearing 9 is arranged on a carrier housing 10 which is connected to the housing 3 by means of a screw connection. Here too, the housing interior 2 is connected to the carrier housing interior 11 .

[0056] The housing 3 forms an axial end region of a tubular axle 12 axially relative to the axis of rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com