Water cover skirt cage type rapid heat storage heat preservation heating boiler

A technology for heating boilers and boilers, which is used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of overheating of multi-burning fuel kang surfaces, high pollution emissions, and inability to provide stable heating for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

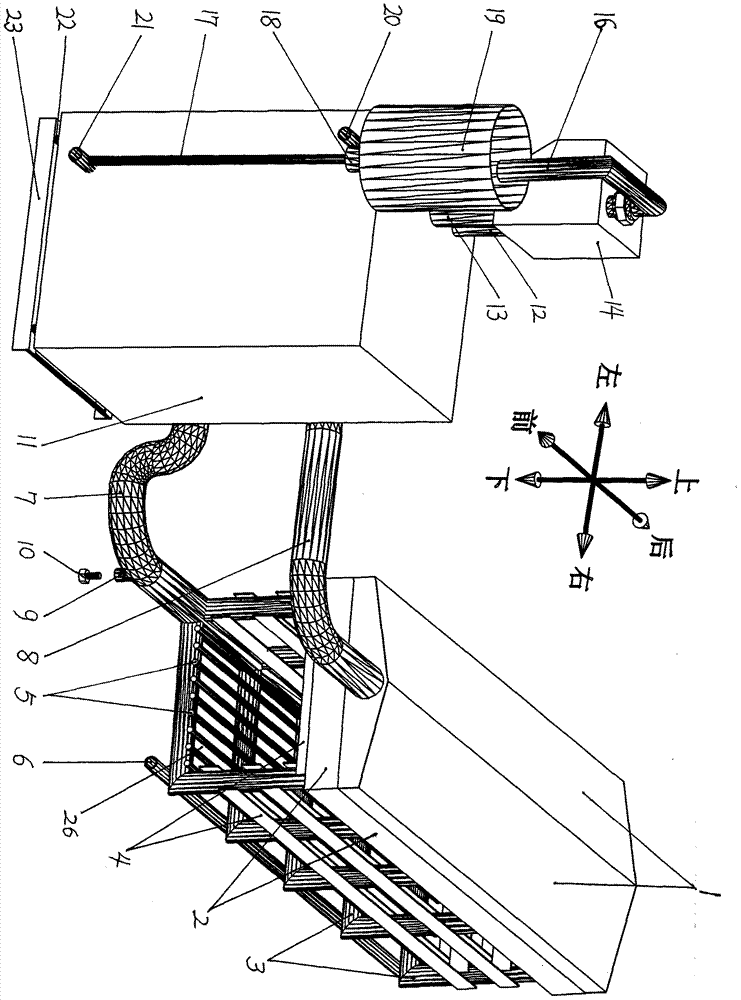

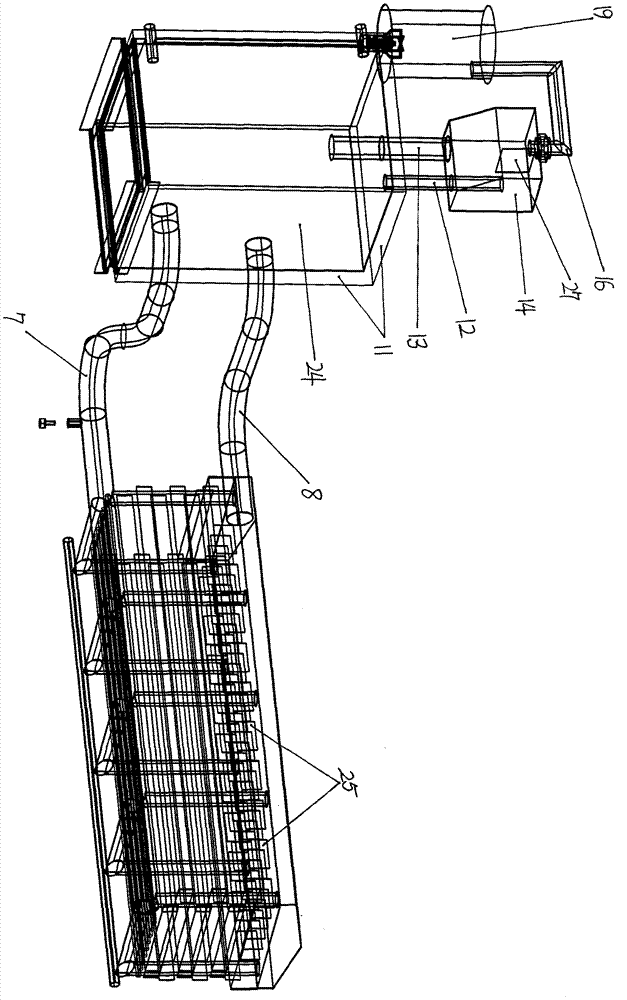

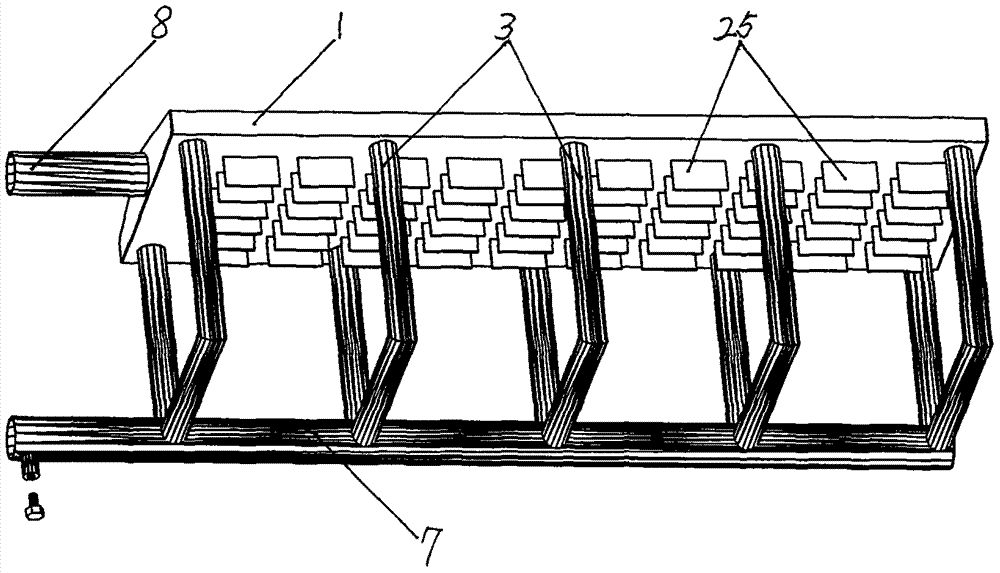

[0020] The standard installation of the water cover skirt cage type fast heat storage and heat preservation heating boiler is installation method 1. After choosing the actual installation method 1, 2 and 3, the positional relationship between the boiler and the heated kang is basically unchanged, and the technical problems to be solved Same as the beneficial effect, the installation methods 1 and 3 are covered by the walls of the house. Therefore, in order to express the positional relationship between the boiler and the kang stove more intuitively and clearly, the preferred embodiment of the boiler installation focuses on the installation method 2. On this basis, it is easy to Understand installation methods one and three. According to the order of overall connection, disassembly and display, and specific installation, the accompanying drawings of the invention take into account the water cover skirt cage boiler, boiler upper water pipe and boiler return pipe, heat storage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com