Engine noise test method

A technology for noise testing and engines, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of a large number of sensors, unintuitive results, and increased test costs, so as to reduce the number of drives, accurate data, and save energy The effect of testing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of this method is as follows:

[0026] 1) Using the CFD numerical analysis method, the engine noise field is simulated to obtain the approximate distribution of the noise field;

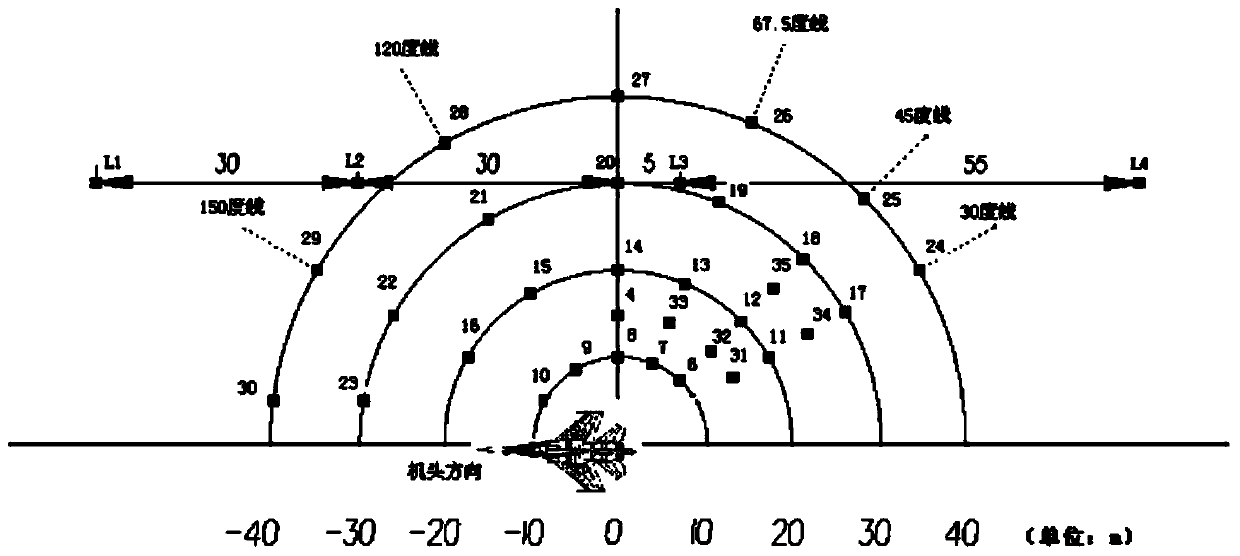

[0027] 2) Determine the location and quantity of sensors. According to the numerical analysis results, the gradient of the noise field behind the aircraft side changes greatly, so more microphones need to be arranged in this area, a total of 23 microphones are arranged; the noise field gradient changes little behind the aircraft side, therefore, the microphones in this area It can be arranged sparsely, with a total of 12 microphones arranged, such as figure 1 shown;

[0028] 3) Select a data acquisition system and data acquisition software that is reliable and suitable for field testing, connect each microphone to the data acquisition system with a test cable, modify the sensitivity of each microphone in the data acquisition software, and use a standard sound sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com