Mask plate and substrate marker manufacturing method

A mask and marking technology, which is applied to the photoengraving process of the pattern surface, the exposure device of the photoengraving process, the instrument, etc., can solve the problems of economic loss, small test marks, unfavorable product monitoring, etc., so as to reduce the production cost and improve the Accuracy and the effect of reducing the difficulty of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

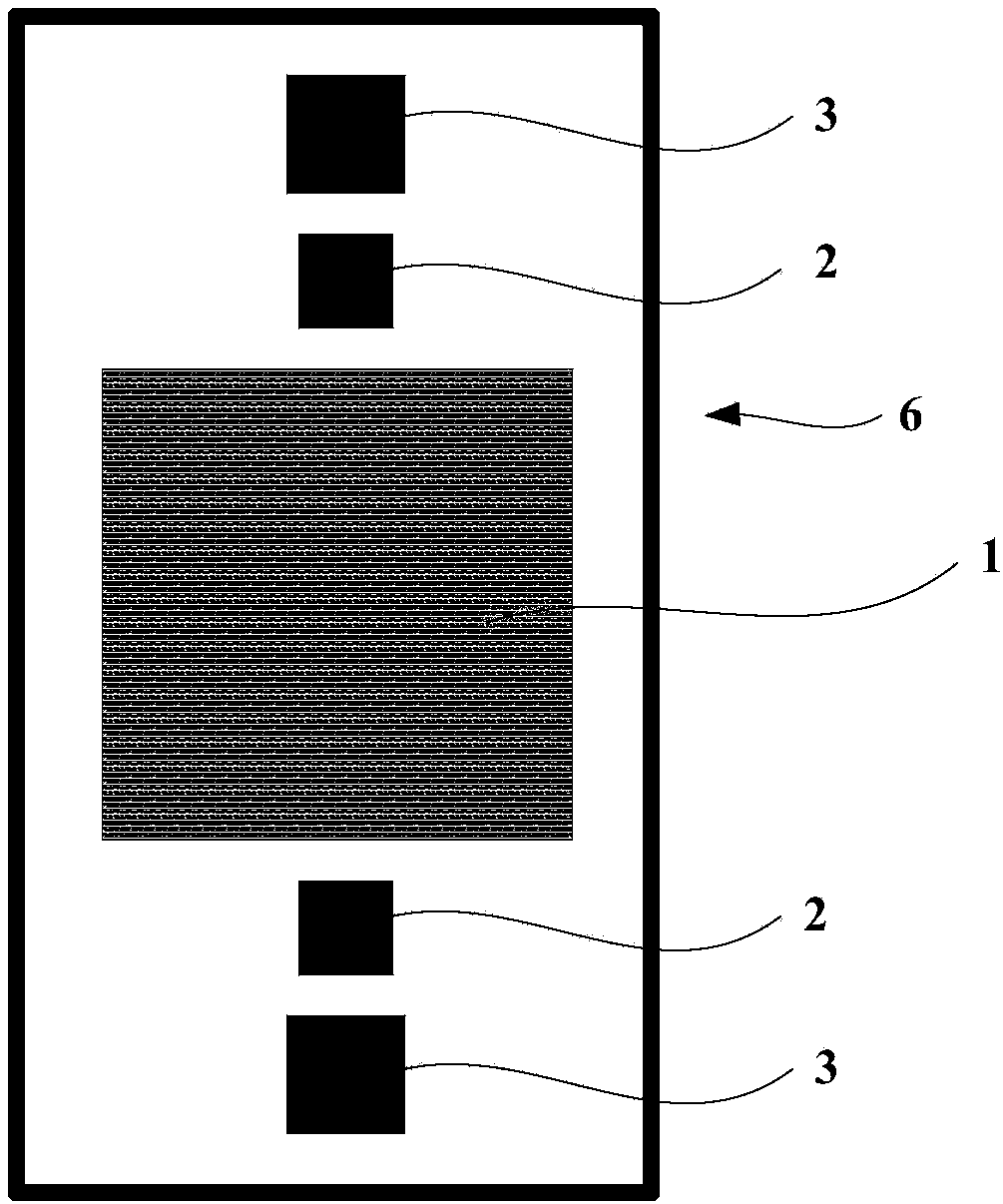

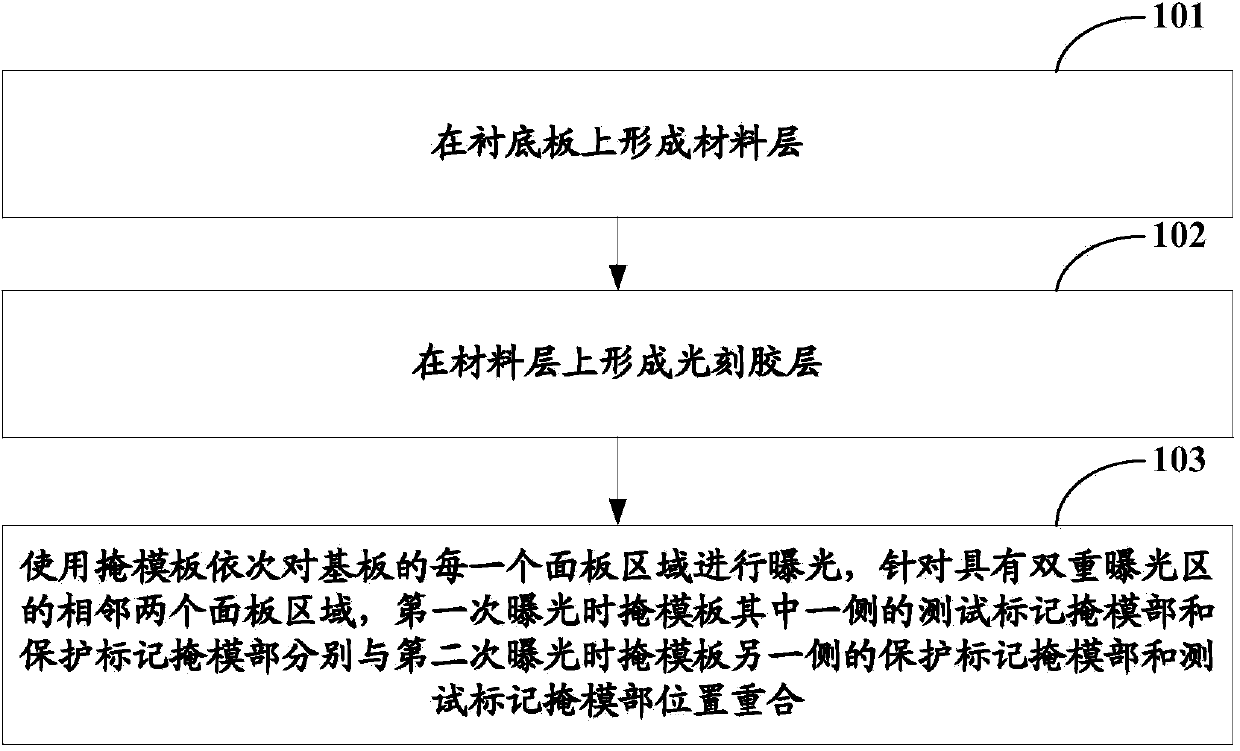

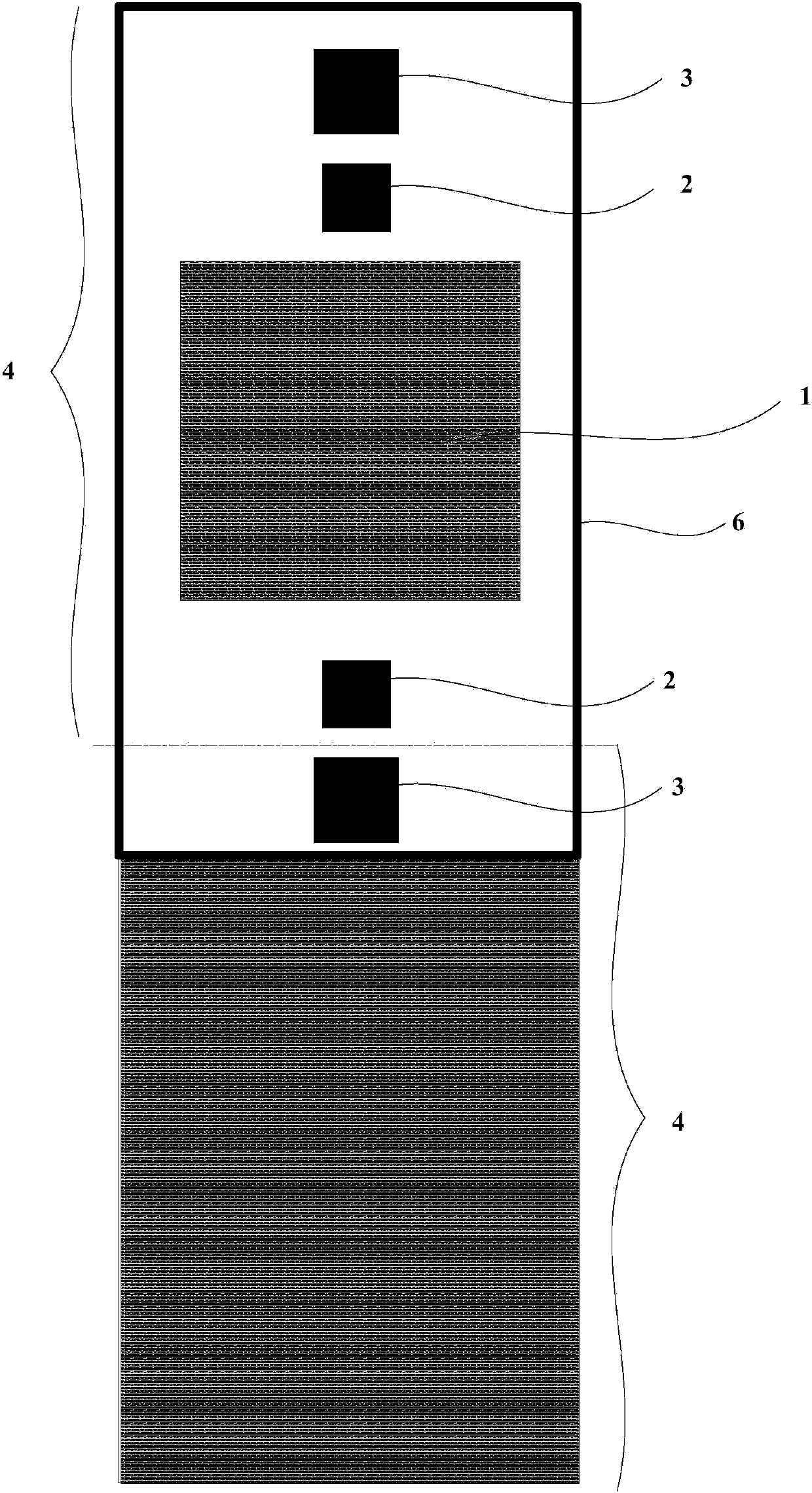

[0020] In order to improve the accuracy of making substrate marks, reduce the difficulty of product monitoring, and reduce production costs, embodiments of the present invention provide a mask and a method for making substrate marks. In the technical solution of the present invention, the graphic outline of the protective mark mask portion of the mask is larger than the graphic outline of the test mark mask portion, and when the mask is used to expose two adjacent panel areas with double exposure areas, even the first There is a positional deviation between the first exposure and the second exposure, and it can also ensure that the graphic outline size of the test mark is consistent with the theoretical design. Therefore, using this substrate marking method can improve the accuracy of substrate marking, reduce the difficulty of product monitoring, and reduce Cost of production.

[0021] In order to make the purpose, technical solution and advantages of the present invention cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com