Evaporated liquor flooded type phase-change heat transfer device for oil-immersed transformer

An oil-immersed transformer and phase-inversion heat technology, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of lowering the working temperature of the transformer, reducing the heat exchange effect, and increasing the difficulty of manufacturing, so as to ensure the service life and reduce the working temperature. The effect of rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

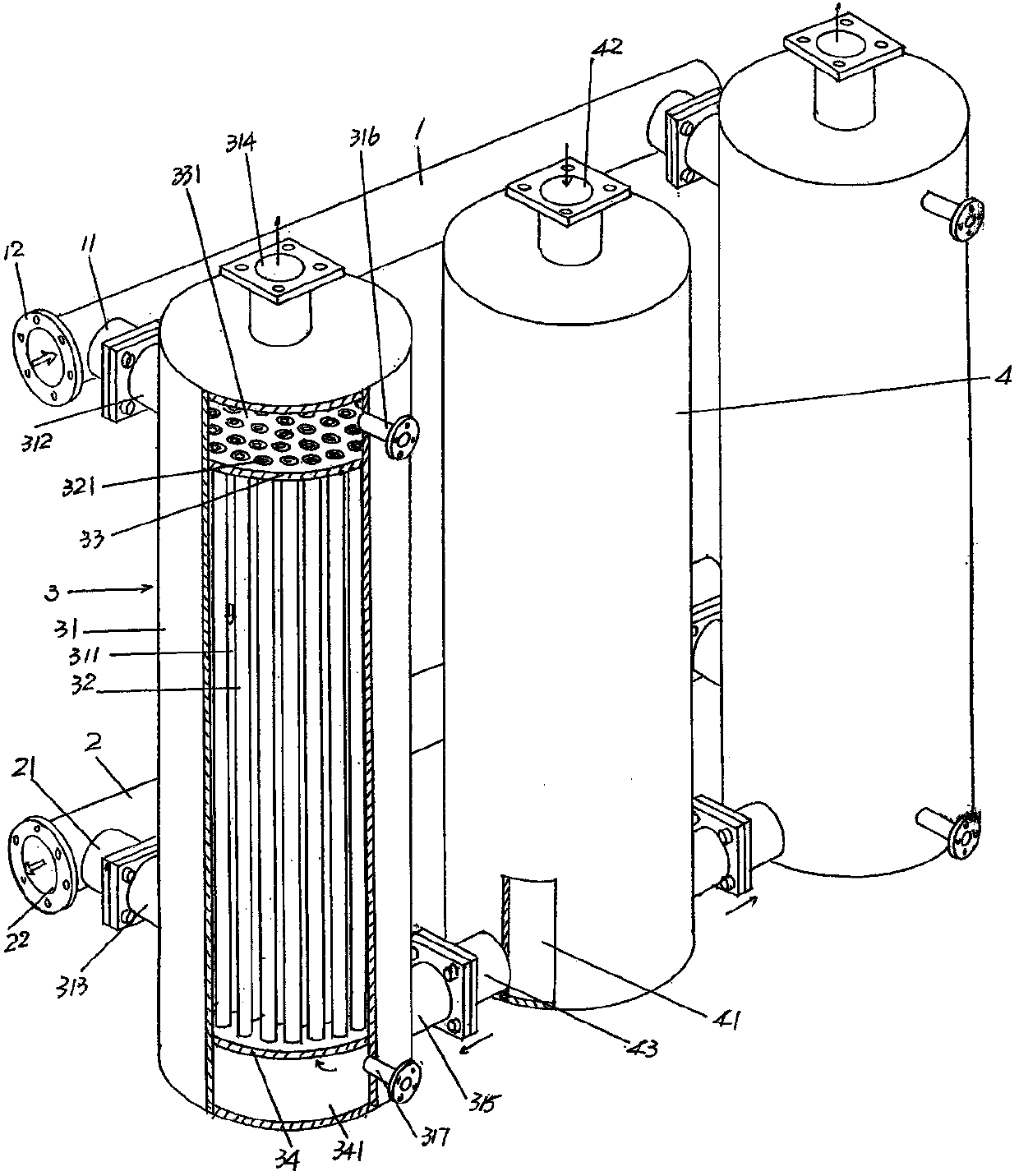

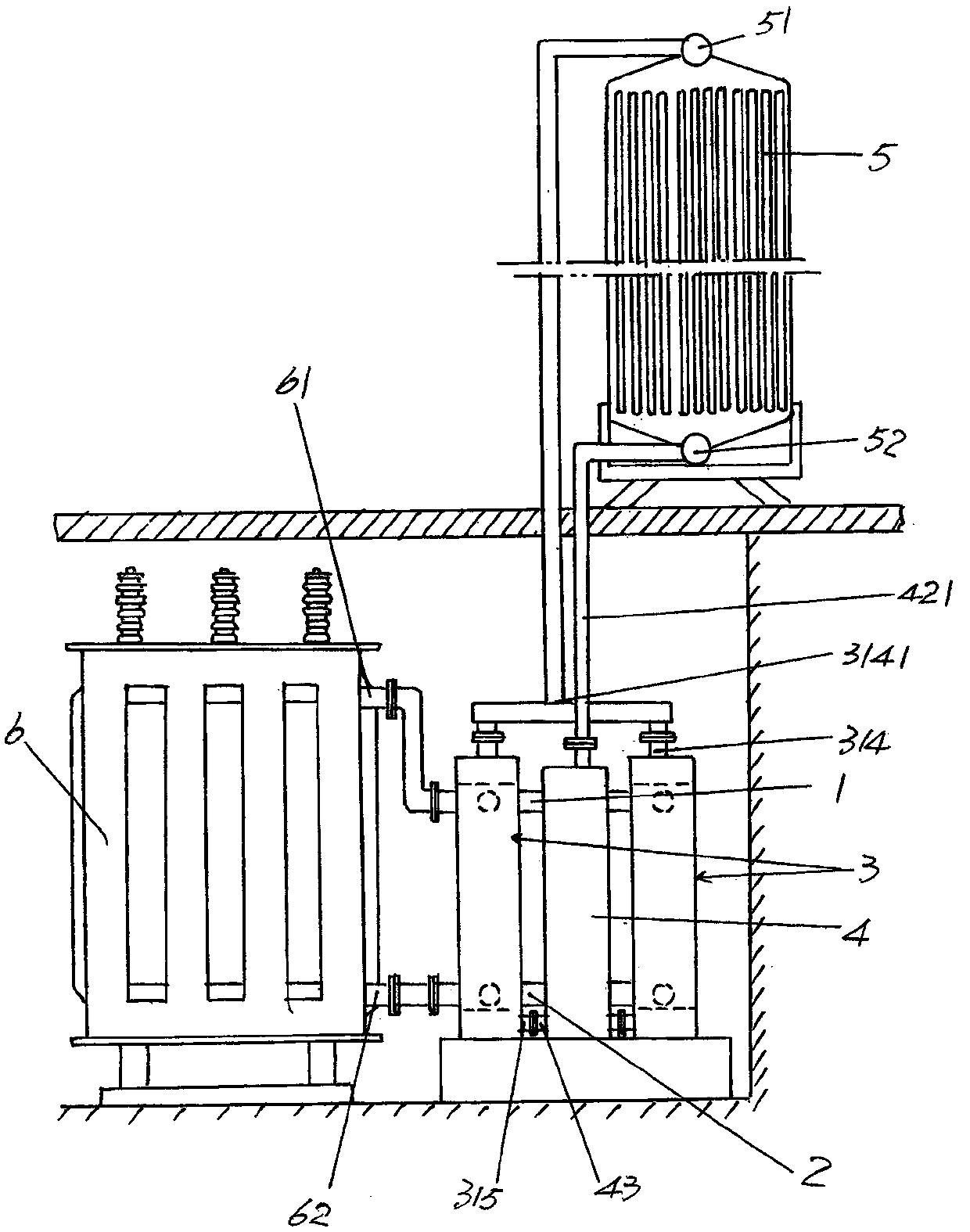

[0020] See figure 1 , an oil inlet manifold 1, an oil return manifold 2 and two evaporators 3 are given. figure 1 The position state shown is an example, an oil inlet manifold fitting flange 12 is formed at the left end of the oil inlet manifold 1, and the oil inlet manifold fitting flange 12 is used for matching with the image 3 The transformer high-temperature oil outlet interface 61 of the shown oil-immersed transformer 6 is connected. An oil return main pipe fitting flange 22 is formed at the left end of the oil return main pipe 2, and the oil return main pipe fitting flange 22 is matched with the transformer low-temperature oil outlet interface 62 of the oil-immersed transformer 6 in use. Since the structures of the two evaporators 3 and the way of connection with the oil inlet main pipe 1 and the oil return main pipe 2 are the same, the applicant will choose one of them in detail below.

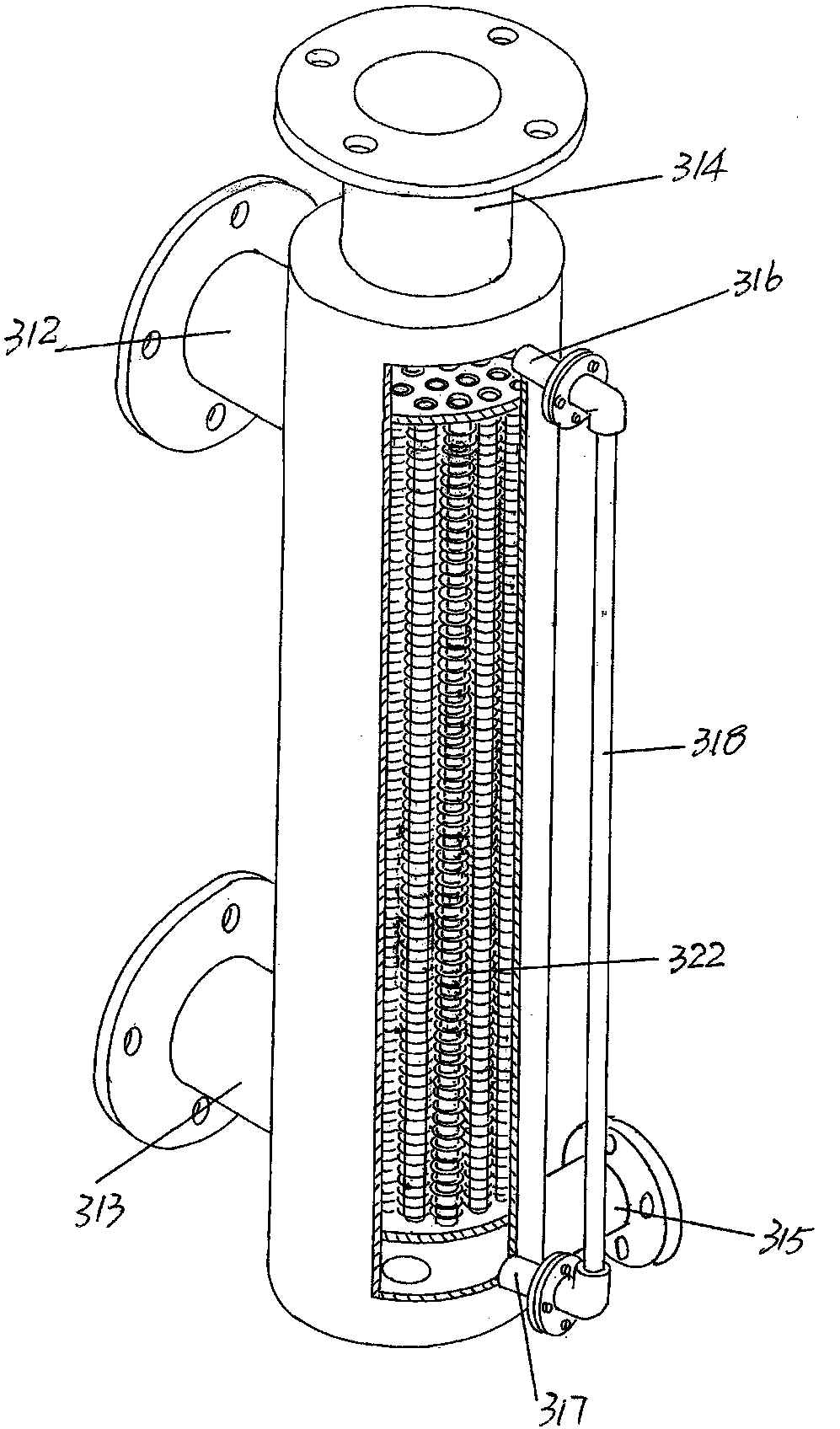

[0021] Aforesaid evaporator 3 comprises tank body 31, the evaporation tube 32 th...

Embodiment 2

[0030] Only the inner diameter and wall thickness of the steel pipe are set to 10 mm and 0.75 mm respectively, and the rest are the same as those described in Embodiment 1.

Embodiment 3

[0032] Only the inner diameter and wall thickness of the steel pipe are set to 14 mm and 0.85 mm respectively, and the rest are the same as those described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com