Ldmos device with double-sloped field plate

A field plate and slope technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of unusable transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

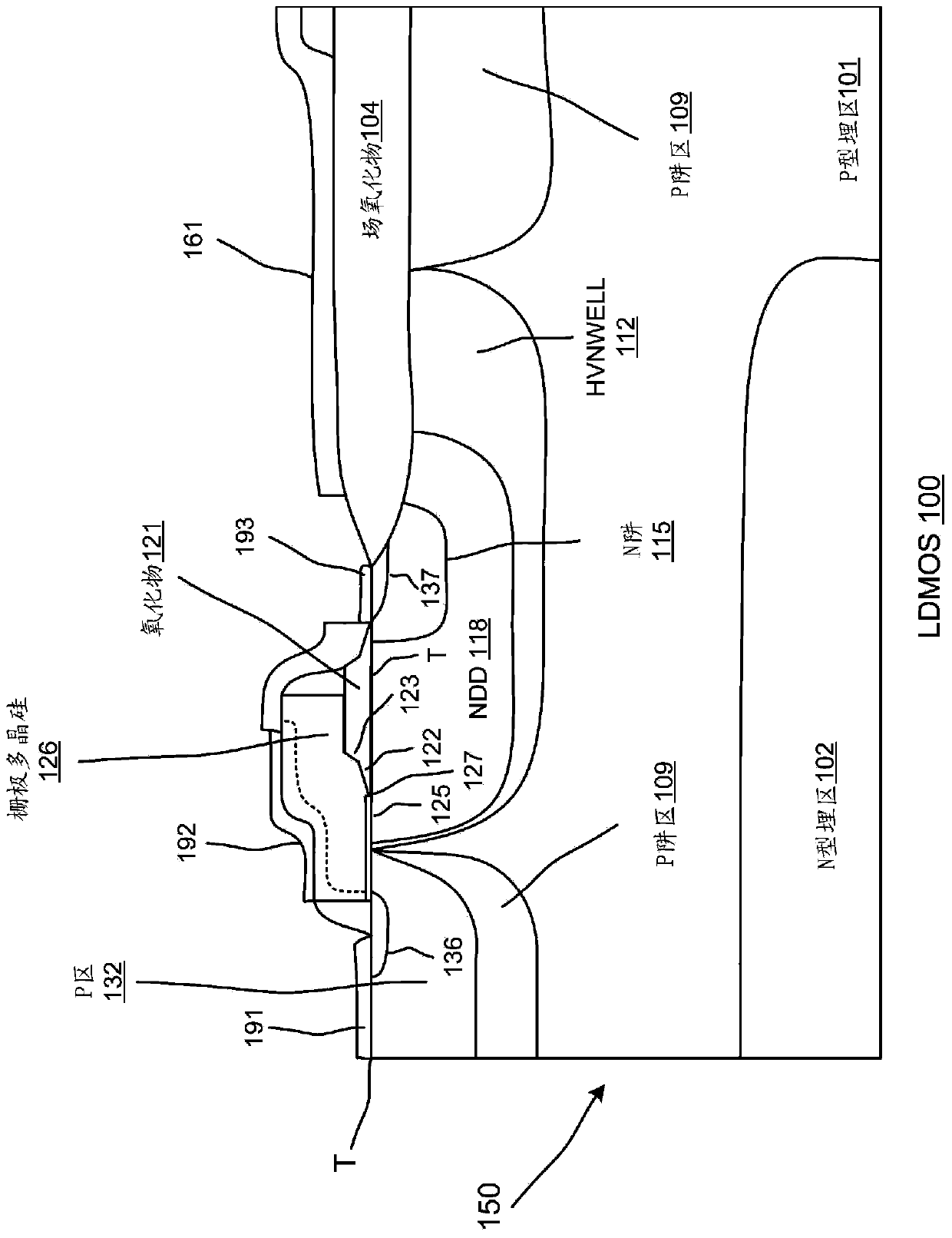

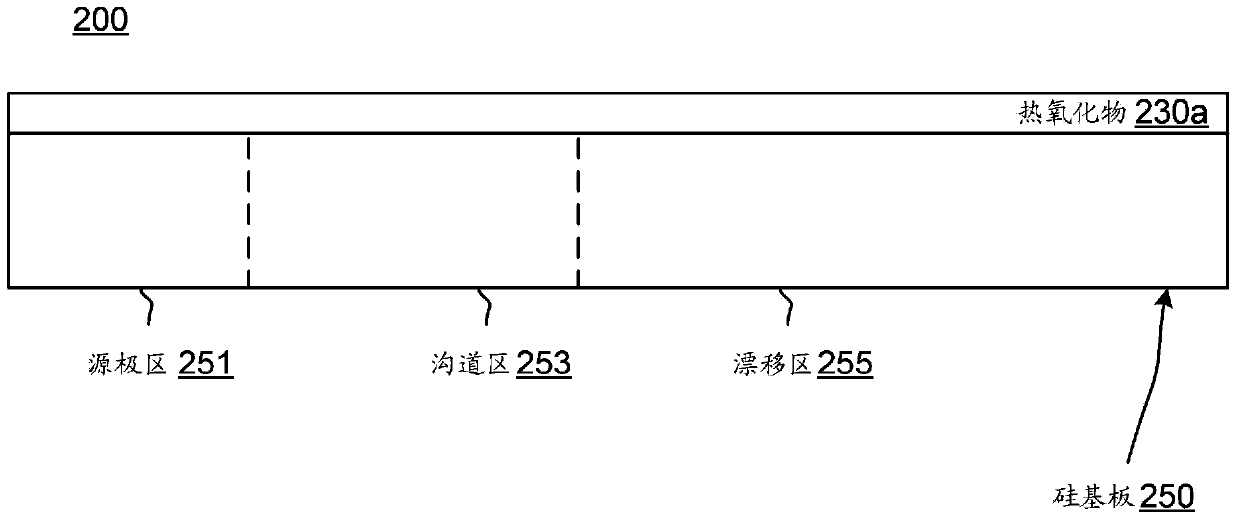

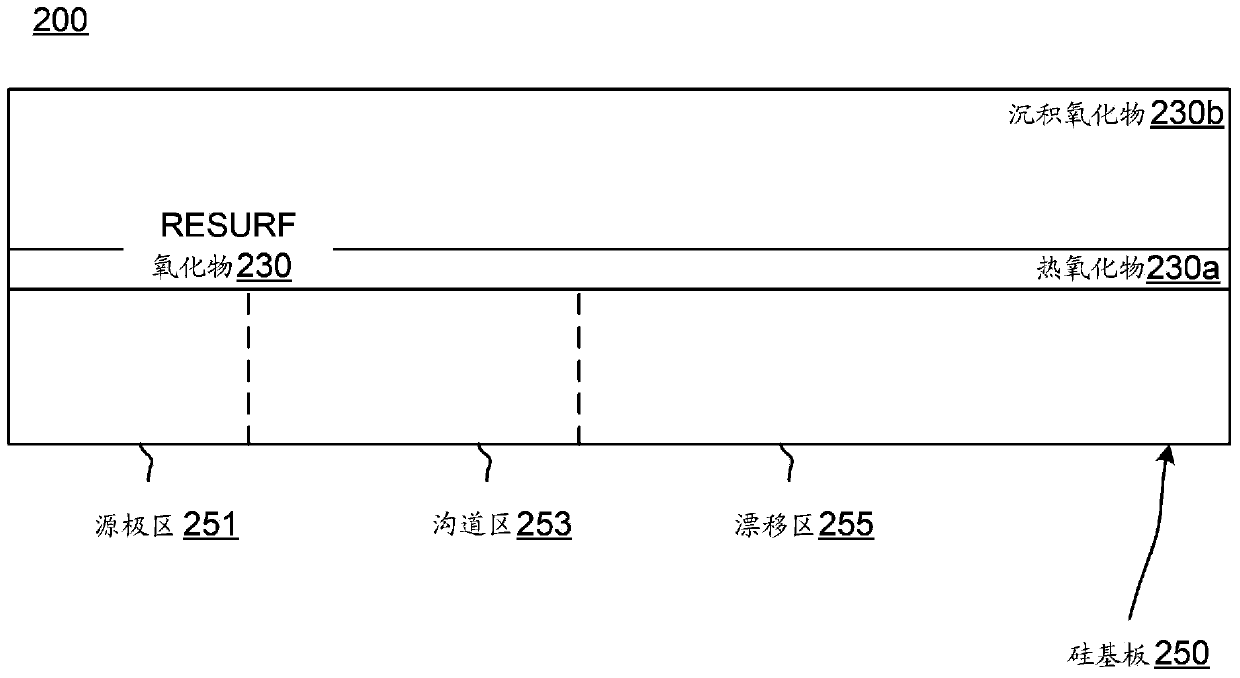

[0012] The disclosure herein relates to semiconductor devices, such as laterally diffused metal-oxide-semiconductor (LDMOS) transistors, having double-slope field plates (which may also be referred to as field dielectric plates or drift field dielectrics). The disclosure herein also relates to corresponding methods for producing such semiconductor devices. Such LDMOS devices with double sloped field plates can be produced with increased drift dose (to lower Rdson), while also having similar or improved breakdown voltage performance.

[0013] Furthermore, by using the semiconductor processing methods described herein, one or more process steps in a semiconductor process that overlap or correspond to one or more process steps used to produce other semiconductor devices (eg, LDMOS transistors) can be used to produce Semiconductor devices (eg, other than LDMOS transistors). For example, a process step used to produce a portion of a first semiconductor device may also be used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com