Non-contact controller for large-power series excitation direct current motor

A series excitation direct current, high-power technology, applied in the field of excitation or armature current control, etc., can solve the problems of short service life, potential safety hazards, poor explosion-proof performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

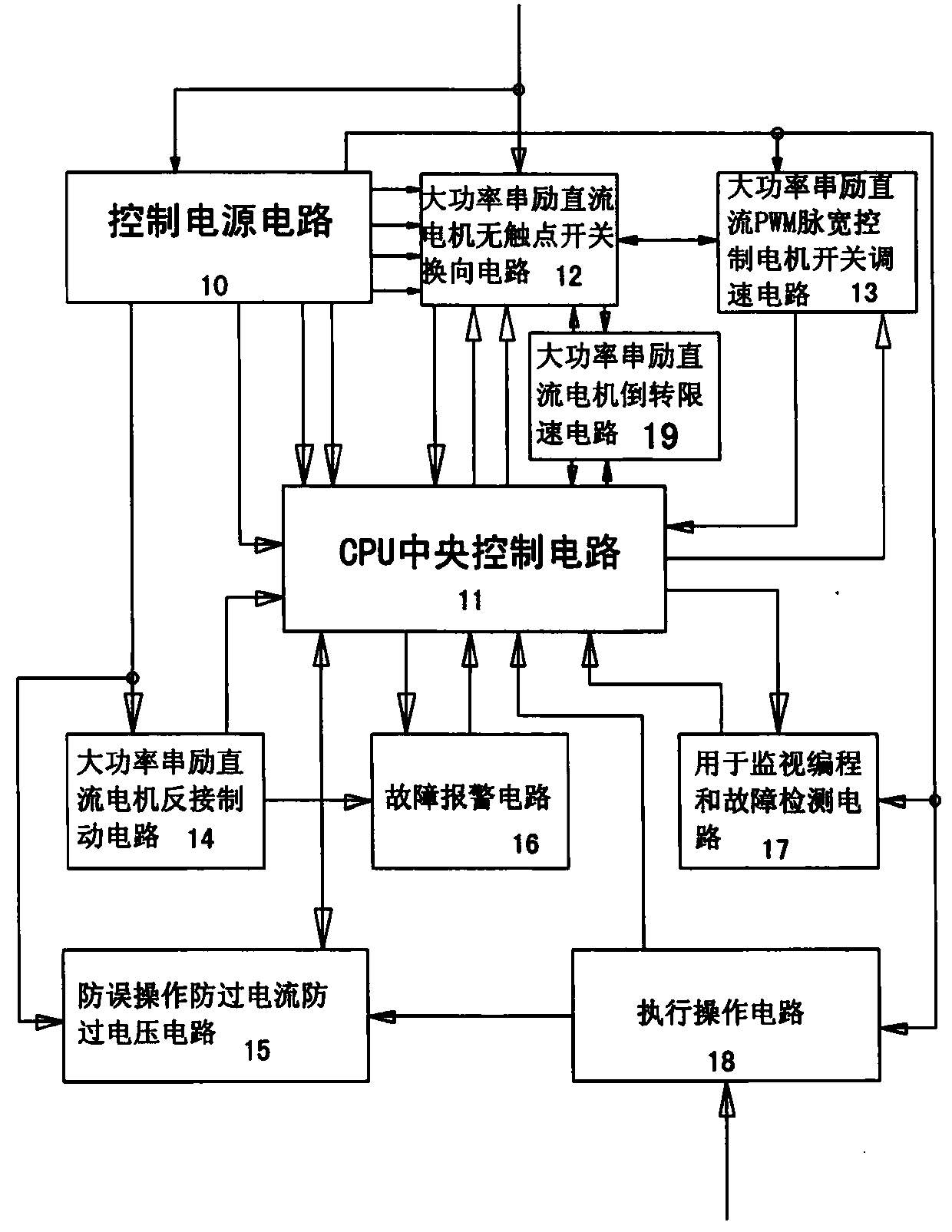

[0019] The invention relates to a non-contact controller of a series-excited DC motor, such as figure 1 — Image 6 It is characterized in that it includes a main circuit and a control circuit. The main circuit includes a control power circuit 10, a high-power series-excited DC motor contactless switch commutation circuit 12, and a high-power series-excited DC PWM pulse width control motor. Switch speed control circuit 13 and CPU central control circuit 11;

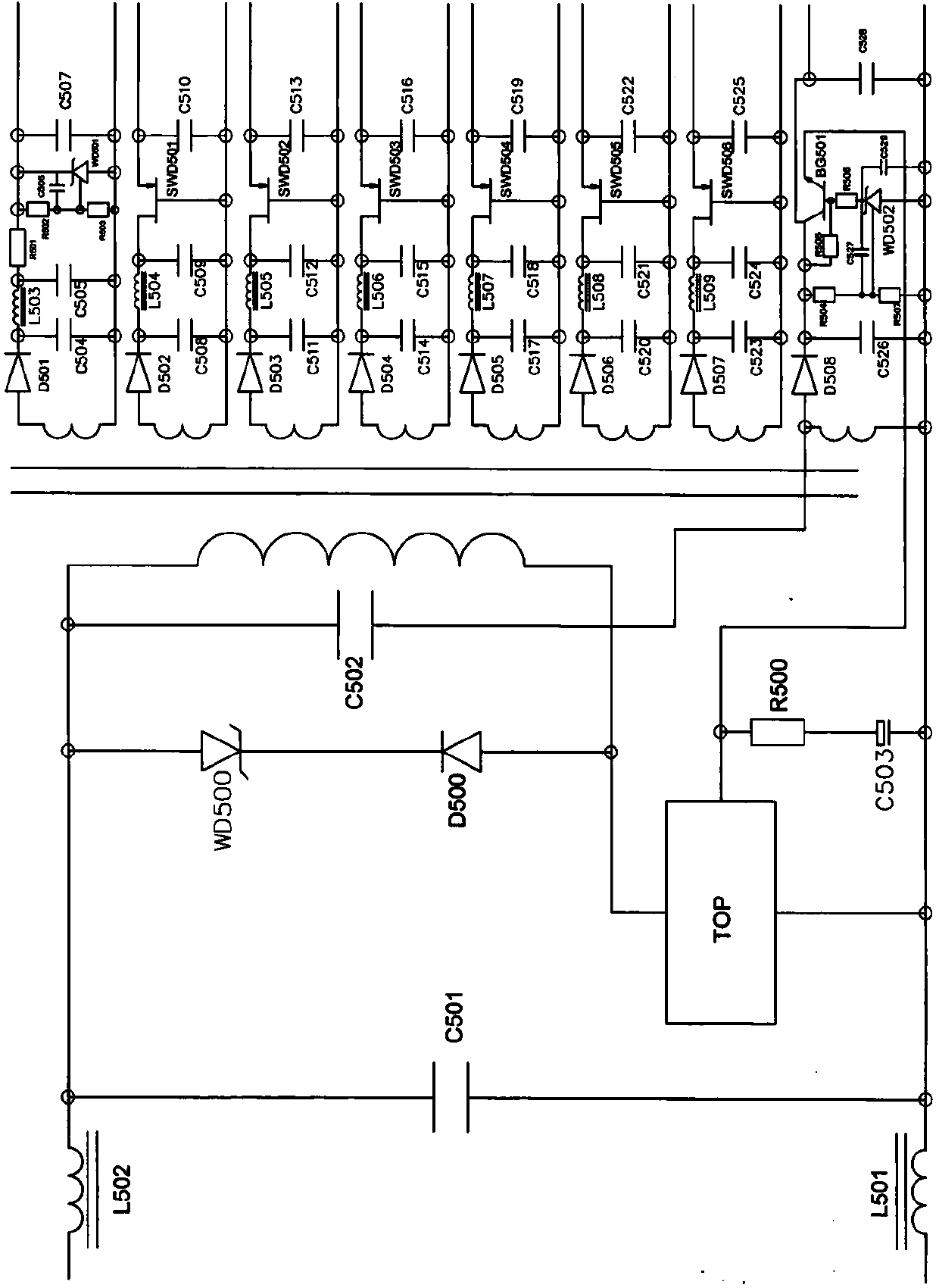

[0020] The control power supply circuit 10 is composed of a TOP switching chip, a high-frequency switching power supply transformer π, a transient diode WD500, the 500th diode D500, the 502nd capacitor C502, the 501st capacitor C501, the 500th resistor R500, and the 503rd electrolytic capacitor C503. High-frequency switching circuit, rectified by high-frequency switching transformer to obtain six sets of mutually independent 15V power supplies;

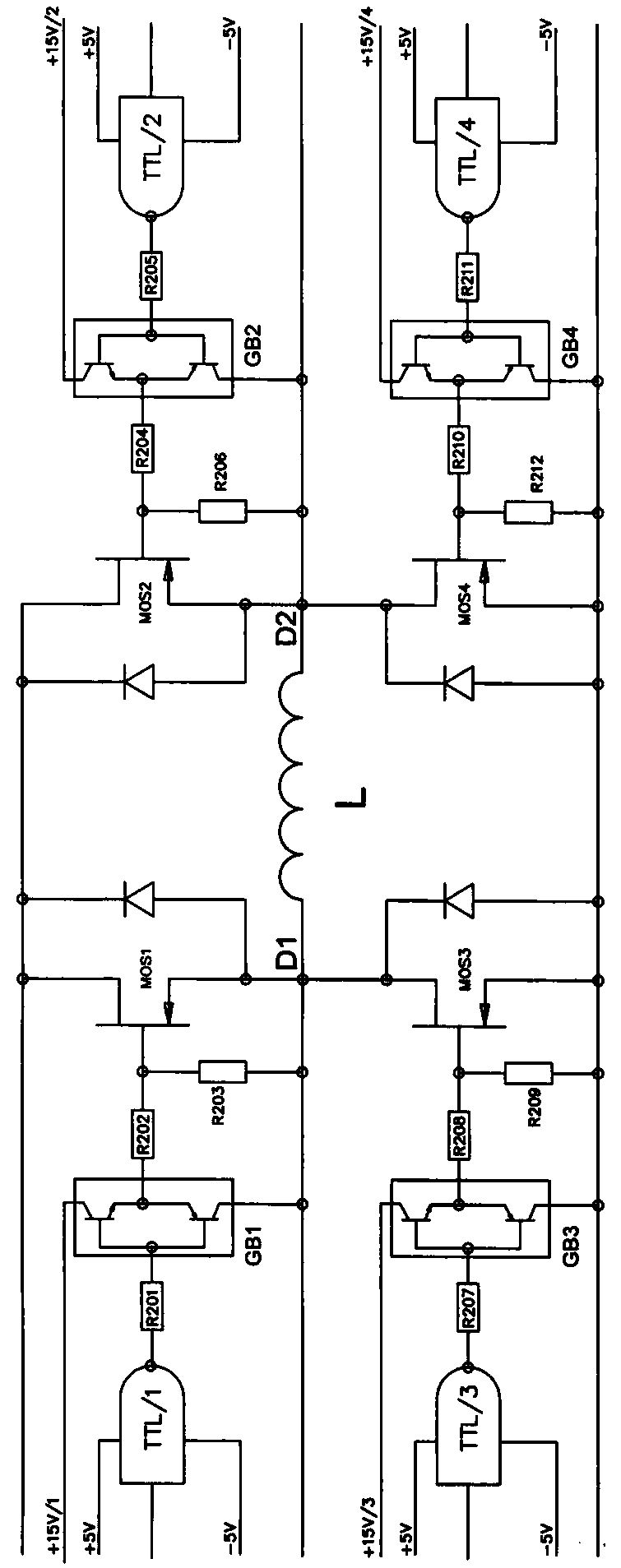

[0021] The described high-power series-excited DC motor contactless switch ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap