Moisture-curable hot melt adhesive

A hot-melt adhesive, moisture-curing technology, applied in the direction of adhesive types, ester copolymer adhesives, polyurea/polyurethane adhesives, etc. problem, to achieve excellent light resistance, improved light resistance, excellent light resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

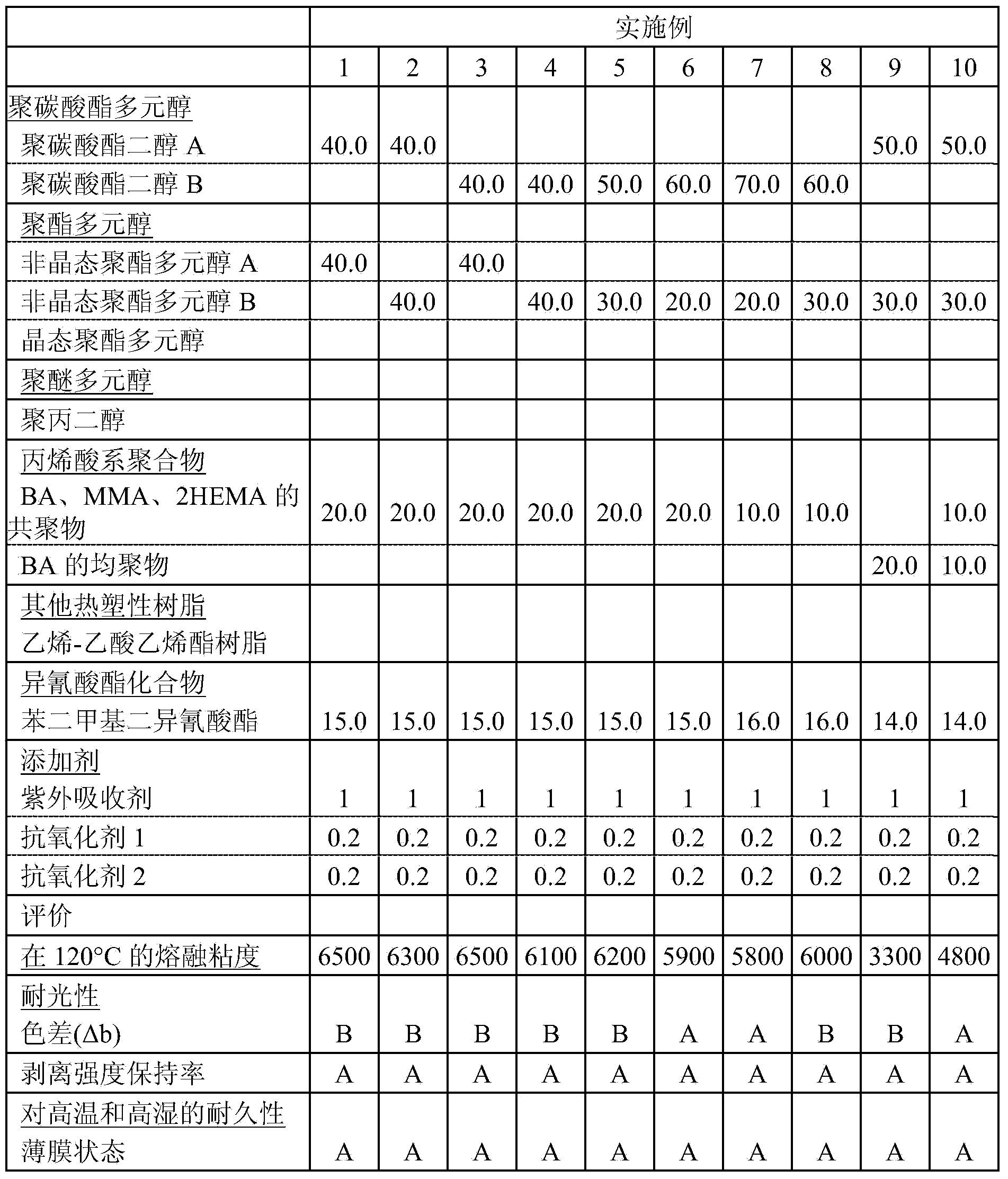

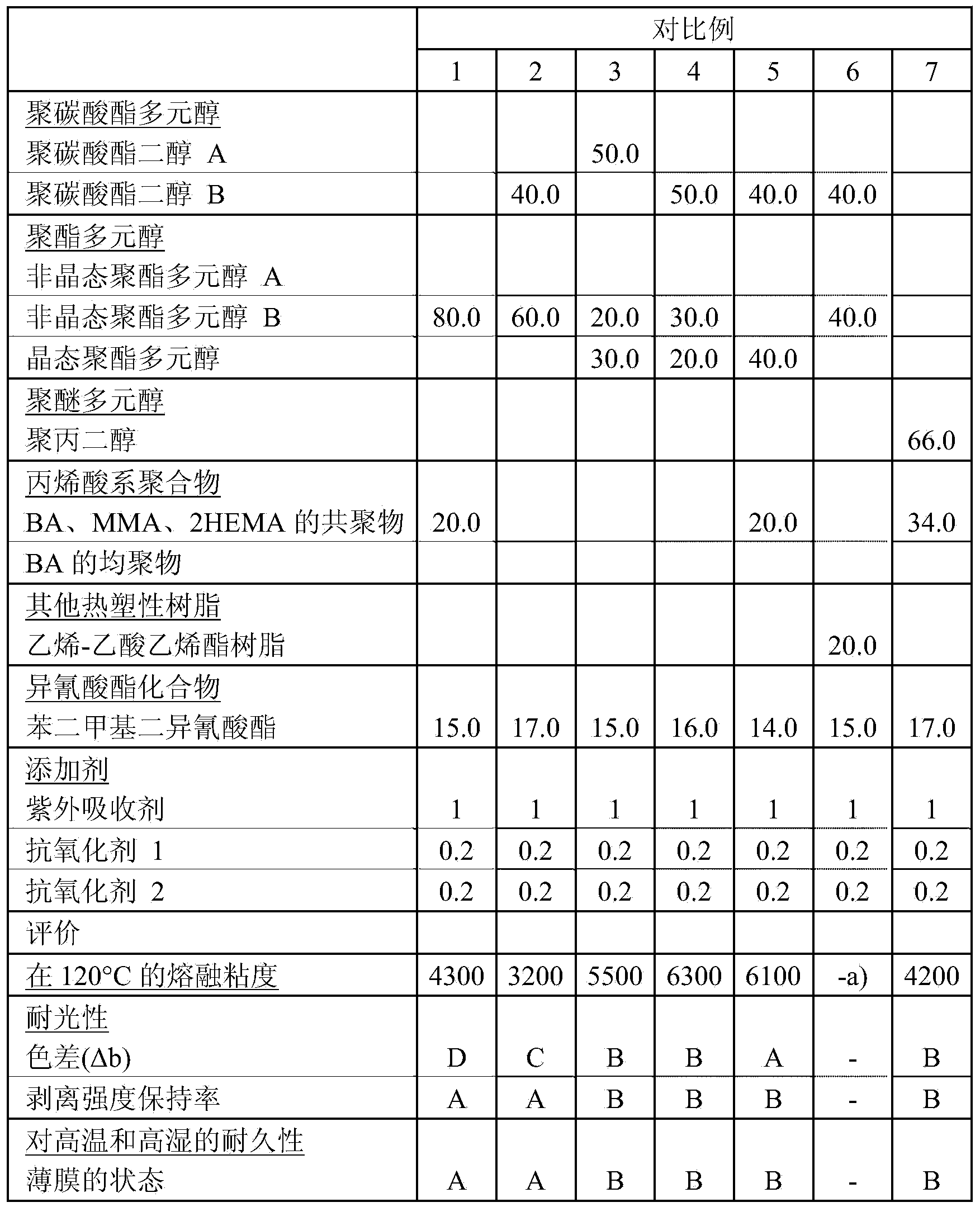

Embodiment 1-10 and comparative example 1-7

[0139] According to the formulations shown in Table 1 and Table 2, the raw materials were mixed to prepare a moisture-curable hot melt adhesive.

[0140] Specifically, all raw materials except the isocyanate compound were charged into a reaction vessel, heated to 120° C., and then stirred under reduced pressure for 1 hour. After removing moisture, an isocyanate compound (xylylene diisocyanate) was added at the same temperature, followed by stirring under reduced pressure for 2 hours to obtain a moisture-curable hot melt adhesive.

[0141] An ultraviolet irradiation test was conducted in order to evaluate the light resistance of the moisture-curable hot-melt adhesives of Examples and Comparative Examples. In addition, a high pressure cocker test was performed as an accelerated test in order to evaluate durability against high temperature and high humidity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com