Double-stage material-pushing centrifuge distribution acceleration plate device

A centrifuge and acceleration disc technology, applied in the field of centrifuges, can solve problems such as acceleration, and achieve the effects of improving the solid-liquid ratio of materials, stabilizing the centrifuging effect, and increasing the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

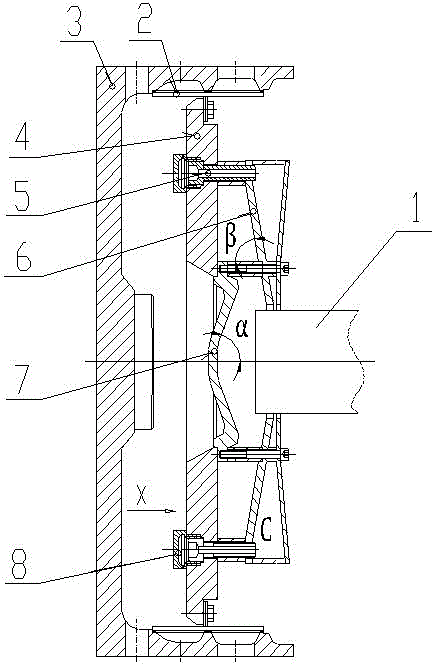

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

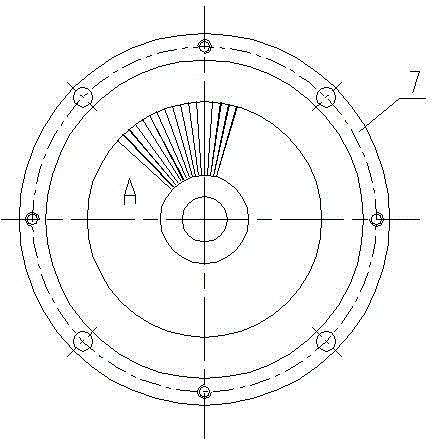

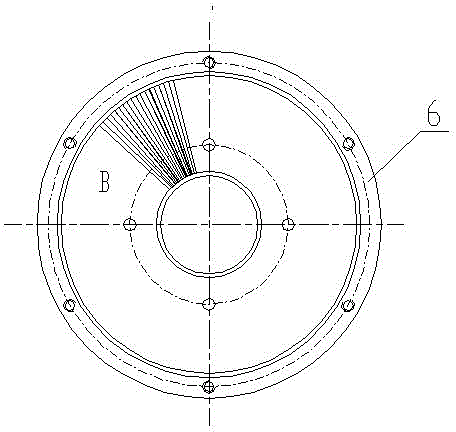

[0023] see figure 1 , the present embodiment is a two-stage pusher centrifuge distribution acceleration disc device, which is designed on the prior art two-stage pusher centrifuge, a pusher plate 4 is arranged in the first-stage rotating hub 3, and the feed pipe 1 is located in a The central part of the first-stage rotating hub 3, between the first-stage rotating hub 3 and the pusher plate 4 is conventionally provided with a first-stage rotating hub screen 2.

[0024] A horn hole is set at the center of the pushing plate 4, and a circular inner distribution acceleration disk 7 is installed on the horn hole, and a circular outer distribution acceleration disk 7 is arranged on the side of the feed pipe 1. 6. A closed space C is provided on the outer side of the outer distribution acceleration disk 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com