Miniature helicopter undercarriage

A technology for helicopters and landing gear, which is applied in the field of aircraft, can solve the problems of time-consuming and laborious assembly of the fuselage, and poor impact resistance of the landing gear, and achieve the effects of saving time, reducing weight and prolonging the service life of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

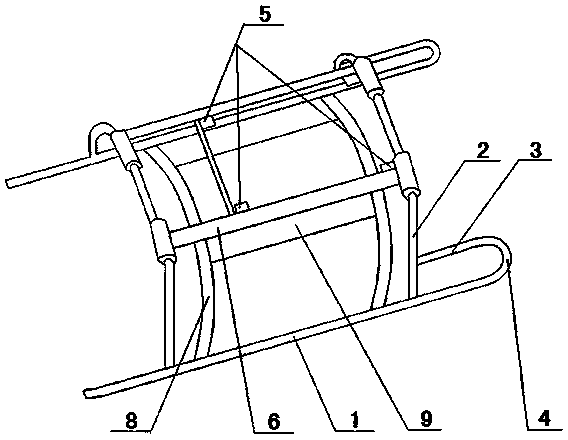

[0023] Such as Figure 1 to Figure 3 Shown, be a kind of micro-helicopter undercarriage that present embodiment proposes, comprise two braces 1 that are arranged in parallel, all be provided with on each brace 1 and brace 1 is the support bar 2 that is set angle inclination, as A preferred embodiment, the inclination angle is 15o. It also includes a cross bar 3 connected to the support bar 2 , and the cross bar 3 is connected to the support foot 1 through a transition bar 4 . In this embodiment, the cross bar 3 is connected with the transition bar 4 in an arc; the transition bar 4 is connected with the support foot 1 in an arc.

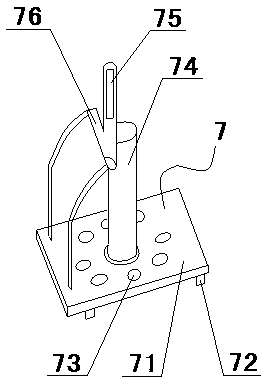

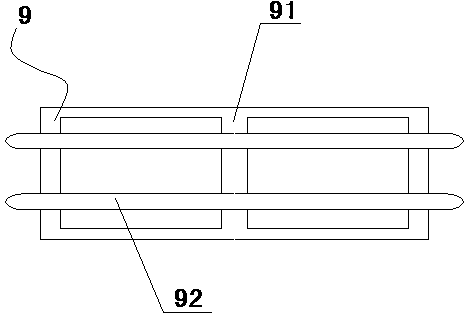

[0024] Mounting bases 6 for installing machine bases 7 are provided between the support rods 2 , and mounting holes 5 in a rectangular distribution are provided on the mounting bases 6 . Wherein, machine base 7 comprises chassis 71 and is located on the shaft seat 74 on chassis 71, and the bottom surface of chassis 71 is provided with the machine ba...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that in this embodiment, the cross bar and the transition bar are connected at right angles, and the cross bar and the support feet are also connected at right angles.

[0031] In this embodiment, a partition for installing the control device is fixedly arranged on one side of the supporting foot, and a through hole for reducing weight is provided on the partition.

[0032] In this embodiment, the landing gear and the machine base are installed together, so that the assembly process is more time-saving and labor-saving, and at the same time, the whole body structure is more compact. At the same time, since there are through holes on the chassis of the machine base and the partition plate, the weight of the whole machine body is reduced, and the disassembly and assembly are more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com