Specific lifting tool for lifting inclined-wedge mechanism of mold

A technology of wedge and spreader, applied in the field of spreader, can solve the problems of difficult installation and disassembly of the wedge, difficult to use general spreader, smashing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] see Image 6 , the present invention is designed to solve the lifting of the inclined wedge mechanism shown in the figure. It can be seen from the figure that the upper part of the inclined wedge 9 is provided with an inclined V-shaped groove 10, and the reset blocks 11 are fixed on both sides of the V-shaped groove, and the lower part of the inclined wedge is a slider 12. , The wedge mechanism is installed in the upper mold base, the installation space is very narrow, and it is difficult to hook with ordinary hooks.

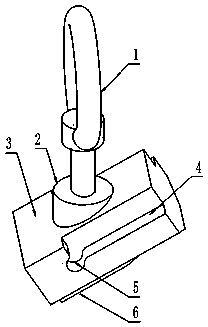

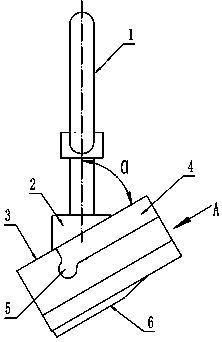

[0021] see Figure 1-4 with Figure 7 , the present invention is designed according to the shape characteristics of the lifted wedge mechanism and lifting requirements, and it includes a lifting seat 3 and a suspension ring 1, and the suspension ring is installed on the top of the lifting seat. Both sides of lifting seat top are symmetrically provided with draw-in groove 4, and the tail end of each guide groove is provided with limit groove 5, and limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com