Multidimensional Buffer Shock Absorber for Construction Vehicle Cab

A technology of engineering vehicles and shock absorbers, which is applied in the direction of high internal friction springs, etc., can solve the problems of vehicle bumps, feet detached from the accelerator pedal and brake pedal, and the driver vacated, so as to achieve the effect of slowing up and down bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

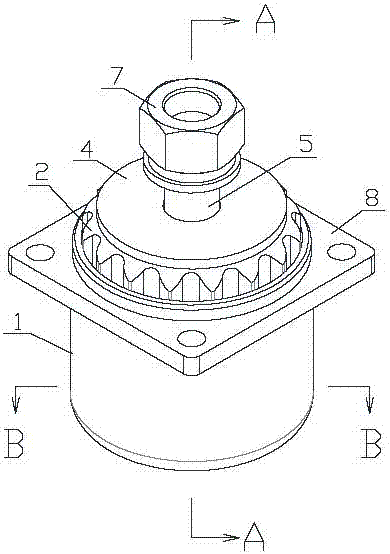

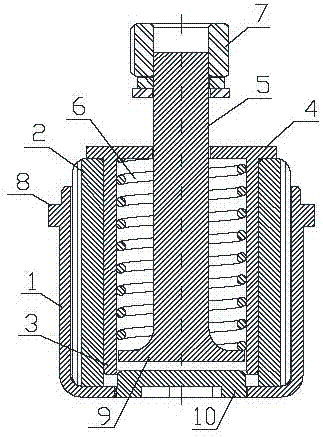

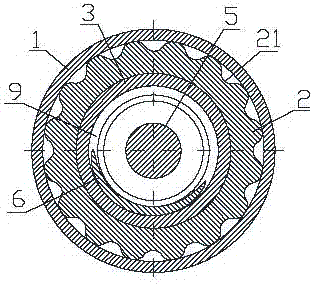

[0013] like figure 1 , figure 2 and image 3 As shown, the present invention is used for the multi-dimensional shock absorber of construction vehicle cab and comprises housing 1, rubber sleeve 2, spring 6, spring sleeve 3, disc 4, spring seat 9, core rod 5, end cap 10, The flange 8 and the fixing nut 7, the front end of the housing 1 is open and the bottom end is centered with a mounting hole, the flange 8 is arranged on the outer ring of the front end of the housing 1, and the outer ring of the rubber sleeve 2 is A plurality of grooves 21 are provided at intervals in the circumferential direction, and each groove axially penetrates the outer ring of the rubber sleeve 2 , the rubber sleeve 2 is arranged in the housing 1 and the outer ring of the rubber sleeve 2 abuts against the housing 1 ring, the spring sleeve 3 is arranged on the inner ring of the rubber sleeve 2 and spaced from the bottom end of the housing 1, and the disc 4 is arranged on the front end of the spring sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com