Aluminum alloy light truck frame and preparation method thereof

An aluminum alloy and light truck technology, applied in bumpers, vehicle safety arrangements, transportation and packaging, etc., can solve the problems of cars drilling into the lower part of trucks, poor corrosion resistance, and crystal softening, so as to avoid alloy softening and reduce Rear collision damage, the effect of strengthening grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

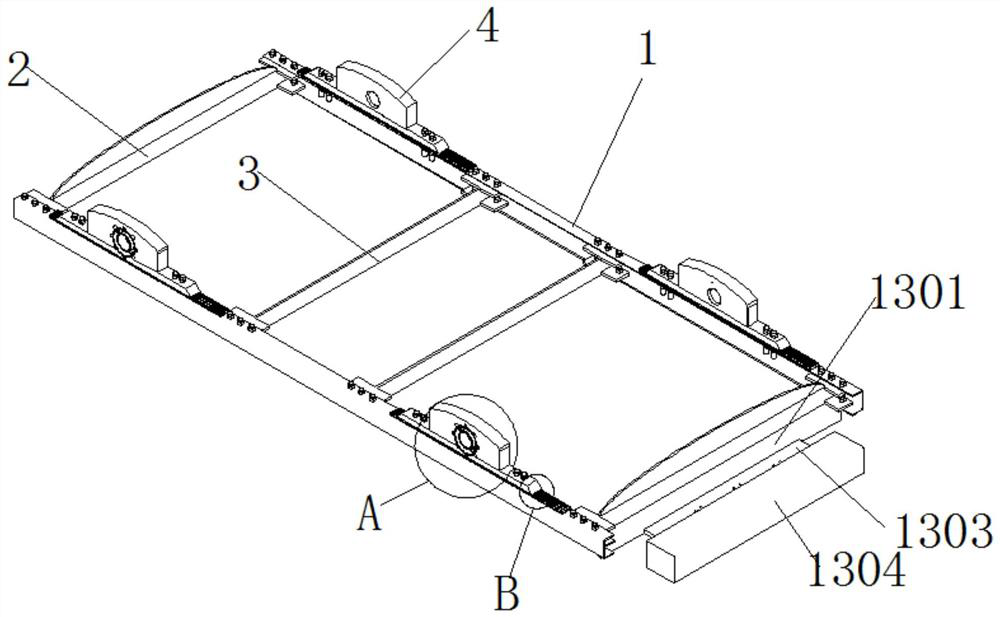

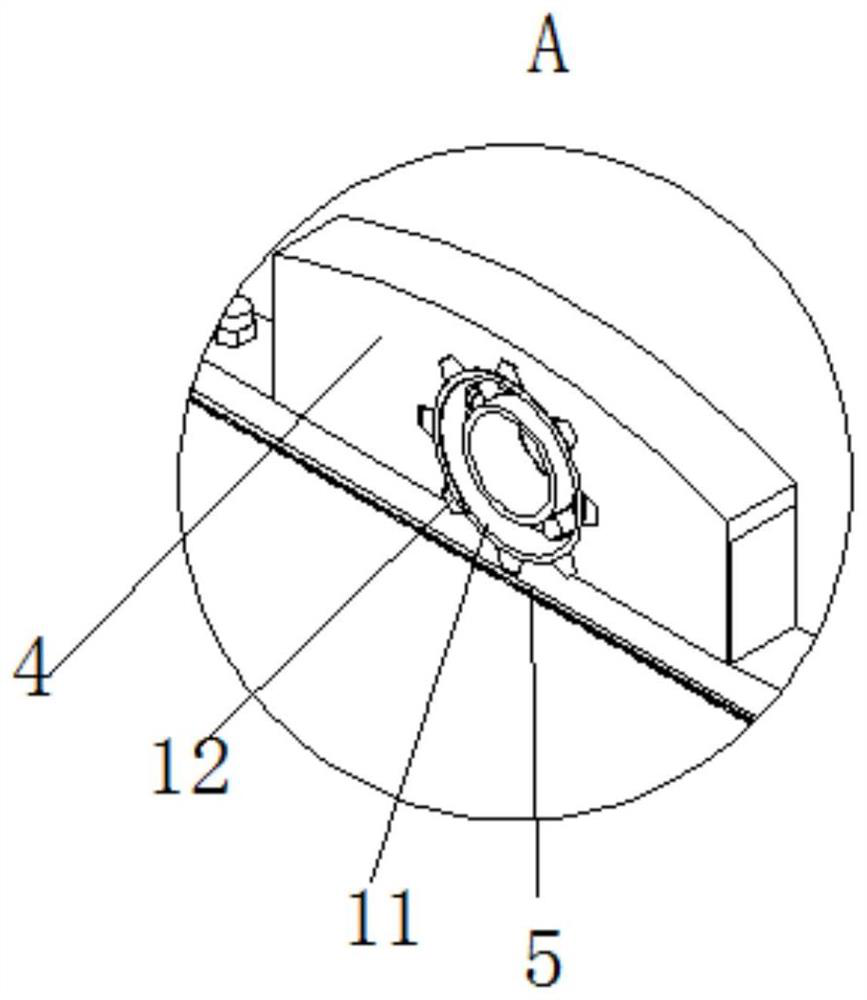

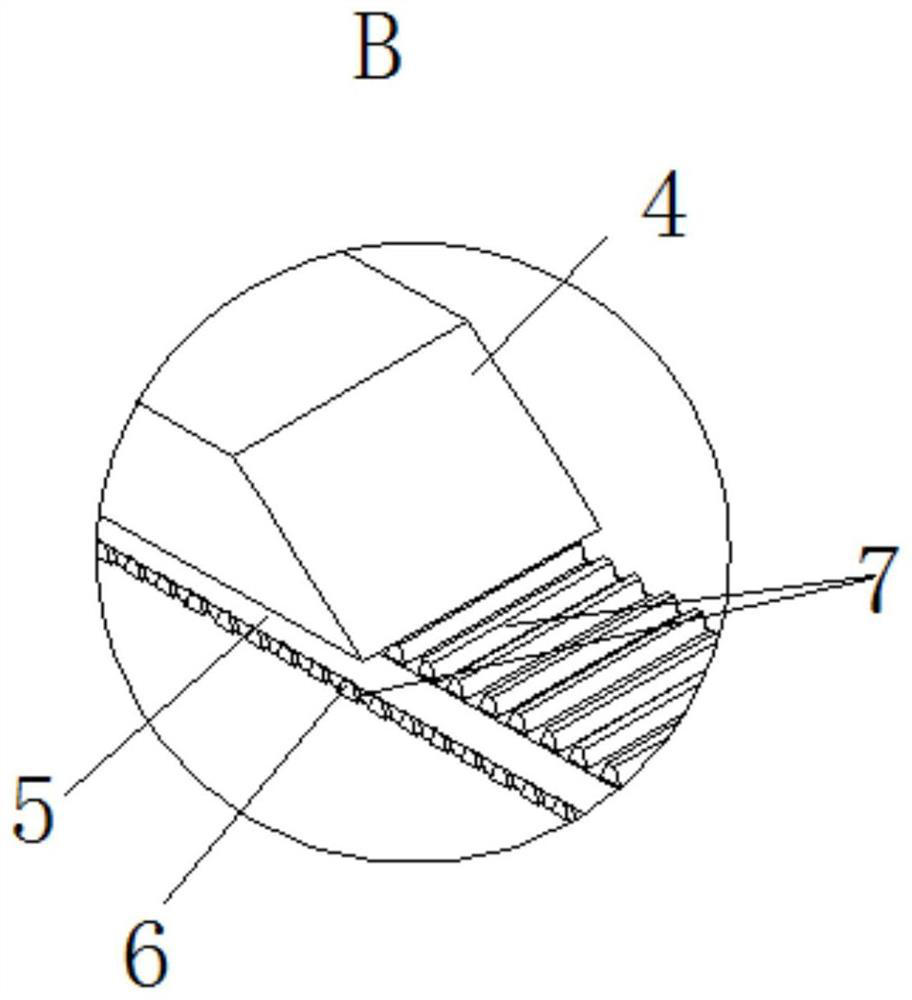

[0038]Embodiment 1 introduces an aluminum alloy light truck frame. A shock absorbing plate 5 is added between the tire mounting seat 4 and the longitudinal beam 1, which can reduce the up and down bumps caused by uneven roads during driving; 7 and reinforcement teeth 3 8, through the interlocking of reinforcement teeth 1 6, reinforcement teeth 2 7 and reinforcement teeth 3 8, the interlocking force in the horizontal direction between the tire mounting seat 4, the longitudinal beam 1 and the shock absorbing plate 5 is increased, and the reinforcement teeth 1 6. Reinforcement tooth 2 7 and reinforcement tooth 3 8 interlock with each other, which can improve the integrity of shock absorbing plate 5, longitudinal beam 1 and tire mounting seat 4, and reduce the occurrence of tire mounting seat 4 and longitudinal beam 1 under the action of the driving wheel. The impact on the bolts caused by relative movement; through the flexible rubber pad 14 fixedly connected to the bearing 11, th...

Embodiment 2

[0042] Embodiment 2 is an improvement on the basis of Embodiment 1. The main improvement is reflected in the addition of an anti-rear-collision mechanism 13, in which the support horizontal plate 1302 can prevent greater casualties caused by the rear-end collision of a car and drilling into the bottom of the truck; A buffer frame 1304 and a buffer spring 1305 are matched to the support horizontal plate 1302, which can reduce the maximum impact force at the moment of a car rear-end collision and reduce rear-end injuries; The buffer frame 1304 will not break away from the support horizontal plate 1302 during the reset process after being compressed. By setting the balance column 16, the buffer frame 1304 can play a guiding role in the compression and reset process, and by setting the ball seat 17 and the ball 18, it can be reduced. Buffer the friction force between the frame 1304 and the balance column 16 during compression and reset. The specific improvements are as follows:

...

Embodiment 3

[0046] Embodiment 3 is based on Embodiment 2 to further illustrate the preparation materials and heat treatment process of the vehicle frame. details as follows.

[0047] The girder is prepared from the following components by mass: 0.001% silicon, 0.01% zirconium, 0.001% iron, 5.5% zinc, 0.8% magnesium, 0.001% manganese, 1.2% copper, 0.05% nickel and 0.08% lanthanum, the rest is metallic aluminum.

[0048] The preparation method comprises the following steps:

[0049] Step 1, solid solution the alloy at 450°C for 120min, then calcined at 470°C for 30min, and then keep it at 440°C for 20min;

[0050] Step 2, quenching the alloy obtained in step 1 with water, after quenching, natural aging for 10 hours;

[0051] Step 3. The alloy obtained in Step 2 was left to stand at 130° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com