An erbium-doped zinc nitride thin-film optical waveguide and its preparation method

A zinc nitride and optical waveguide technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of optical waveguide that cannot obtain luminous efficiency, low refractive index of erbium-doped zinc nitride film, and poor range distribution shape, etc., to achieve Improved luminous efficiency, low cost, and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

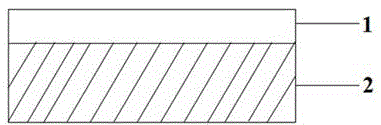

[0028] (1) Zinc nitride film 1 on quartz glass substrate 2 (such as figure 1 shown) to perform optical surface polishing, cleaning and drying; wherein, the thickness of the zinc nitride film 1 is 100-800nm;

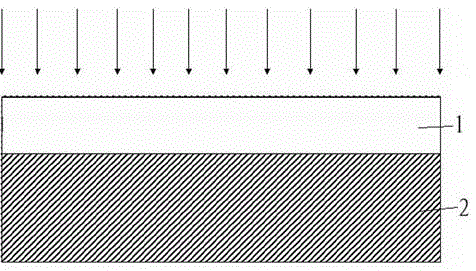

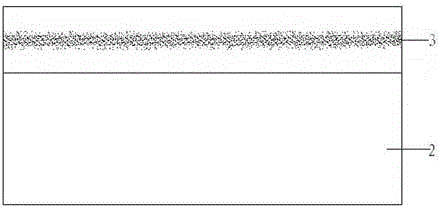

[0029] (2) Put the processed zinc nitride film into the accelerator target chamber and pump it to 10 -4 The background vacuum of Pa, using erbium ions as implanted ions, carries out the process of implanting erbium ions into zinc nitride thin films (such as figure 2 shown); adjust the irradiation energy to 500KeV, and the implant dose to 5×10 15 ions / cm 2 , the beam density is 0.5μA / cm 2 , the angle between the normal direction of the surface of the zinc nitride film and the direction of the incident ion beam is 7°; the sample of erbium-doped zinc nitride film 3 is obtained;

[0030] (3) Place the sample of erbium-doped zinc nitride thin film 3 in a nitriding furnace for annealing to obtain an erbium-doped zinc nitride thin film optical waveguide 4; wherein, the anne...

Embodiment 2-9

[0033] The operation steps are the same as in Example 1, and the involved parameters "irradiation energy, implant dose, angle, annealing temperature, and nitrogen gas volume" are shown in Table 1;

[0034] Table 1:

[0035]

A

B

angle

C

D

E

F

G

Example 2

300

5×10 15

7°

400

500

50-130

31%

12%

Example 3

600

5×10 15

7°

400

500

120-200

32%

11%

Example 4

500

10 14

7°

400

500

100-170

38%

9%

Example 5

500

10 16

7°

400

500

80-170

29%

8%

Example 6

500

5×10 15

7°

300

500

110-190

24%

10%

Example 7

500

5×10 15

7°

800

500

100-180

45%

5%

Example 8

500

5×10 15

7°

800

300

80-200

44%

4%

Example 9

500

5×10 15

7°

800

600

90-190

45%

6%

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com