Erbium-doped zinc nitride thin film optical waveguide and preparation method

A zinc nitride and optical waveguide technology, which is applied to optical waveguides, light guides, optics, etc., can solve the problems of low refractive index of erbium-doped zinc nitride films, inability to obtain luminous efficiency optical waveguides, and poor range distribution. Improved luminous efficiency, low cost and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

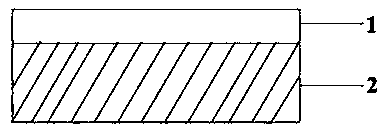

[0028] (1) Zinc nitride film 1 on quartz glass substrate 2 (such as figure 1 shown) to perform optical surface polishing, cleaning and drying; wherein, the thickness of the zinc nitride film 1 is 100-800nm;

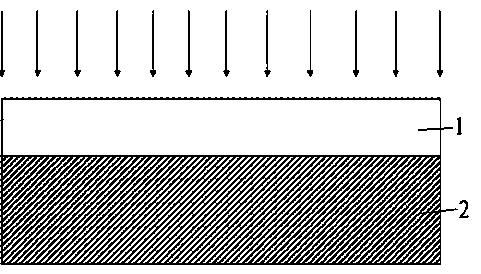

[0029] (2) Put the processed zinc nitride film into the accelerator target chamber and pump it to 10 -4 The background vacuum of Pa, using erbium ions as implanted ions, carries out the process of implanting erbium ions into zinc nitride thin films (such as figure 2 shown); adjust the irradiation energy to 500KeV, and the implant dose to 5×10 15 ions / cm 2 , the beam density is 0.5μA / cm 2 , the angle between the normal direction of the surface of the zinc nitride film and the direction of the incident ion beam is 7°; the sample of the erbium-doped zinc nitride film 3 is obtained;

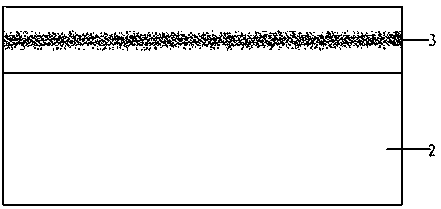

[0030] (3) Place the sample of erbium-doped zinc nitride thin film 3 in a nitriding furnace for annealing to obtain an erbium-doped zinc nitride thin film optical waveguide 4; where...

Embodiment 2-9

[0033] The operation steps are the same as in Example 1, and the involved parameters "irradiation energy, implant dose, angle, annealing temperature, and nitrogen gas volume" are shown in Table 1;

[0034] Table 1:

[0035] A B angle C D E F G Example 2 300 5×10 15 7° 400 500 50-130 31% 12% Example 3 600 5×10 15 7° 400 500 120-200 32% 11% Example 4 500 10 14 7° 400 500 100-170 38% 9% Example 5 500 10 16 7° 400 500 80-170 29% 8% Example 6 500 5×10 15 7° 300 500 110-190 24% 10% Example 7 500 5×10 15 7° 800 500 100-180 45% 5% Example 8 500 5×10 15 7° 800 300 80-200 44% 4% Example 9 500 5×10 15 7° 800 600 90-190 45% 6%

[0036] in FIG. 1:

[0037] A is the irradiation energy (KeV);

[0038] B is the injection dose (ions / cm 2 );

[0039] C is the annealing temperature (℃);

[0040] D is the amount of nitrogen (sccm);

[0041] E is the irrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com