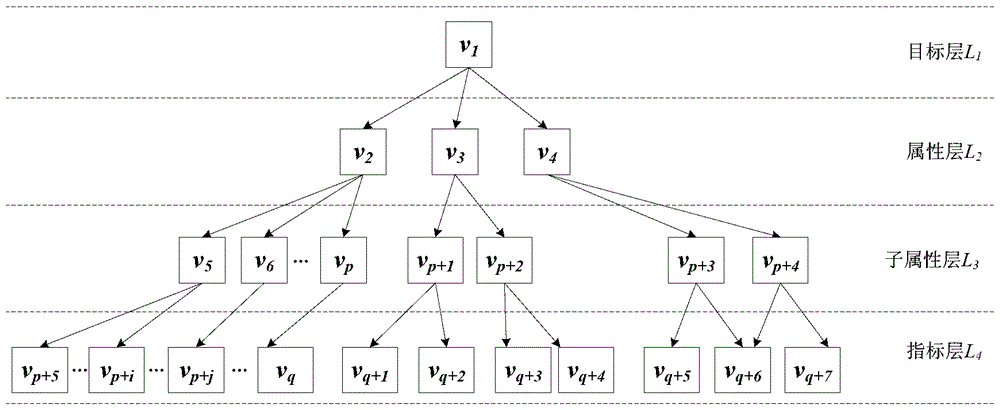

A method for prioritizing aero-engine assembly tasks

A technology of aero-engine and sorting method, which is applied in the fields of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as poor effect and difficulty in multi-factor coordination, and achieve the effect of reducing information loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

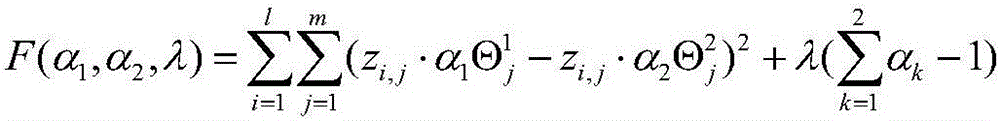

Method used

Image

Examples

Embodiment Construction

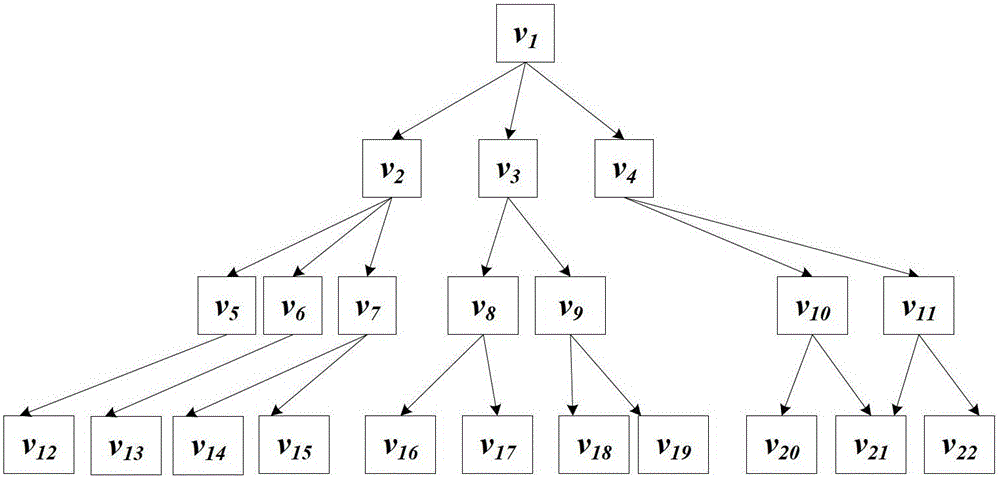

[0068] The present invention will be described below in conjunction with specific embodiments:

[0069] In this embodiment, the aero engine assembly workshop of an enterprise undertakes four production types of assembly tasks including development, mass production, maintenance, and overhaul of a certain type of aero engine. There are three production lines PL 1 ,PL 2 ,PL 3 , The maximum load is 5, 10, 8 in sequence, and the current load is 3, 7, 4 in sequence, and the unit is one. Different types of tasks are mixed and executed on three production lines. The user side of the whole machine includes CAC, SAC and XAC (the degree of influence on task priority is from strong to weak, and the index value is 0.75, 0.50, 0.25). This type of aero engine includes three unit bodies (ET 1 ,ET 2 ,ET 3 ), unit cell ET 1 Corresponding part P 1 , Unit body ET 2 Corresponding part P 2 , Unit body ET 3 Corresponding part P 3 ,P 4 . There are five assembly tasks in the batch plan T 1 ,T 2 ,T 3 ,T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com