A main transformer oil flow guiding microcirculation device and using method

A technology of oil flow and oil temperature, which is applied in the field of main transformer oil flow oriented microcirculation device, can solve the problems of burning the main transformer, bubble bridging discharge failure, turbulent flow and bubble generation, etc., to achieve enhanced cooling effect, improved cooling efficiency and safety performance, the effect of avoiding turbulence and air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below.

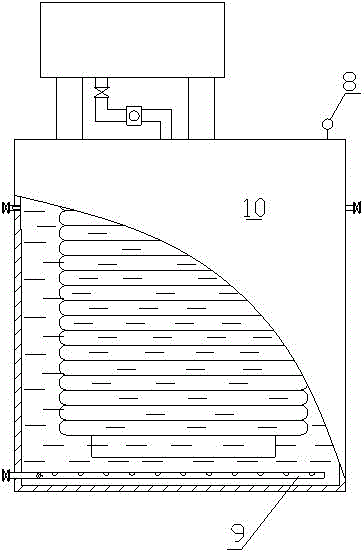

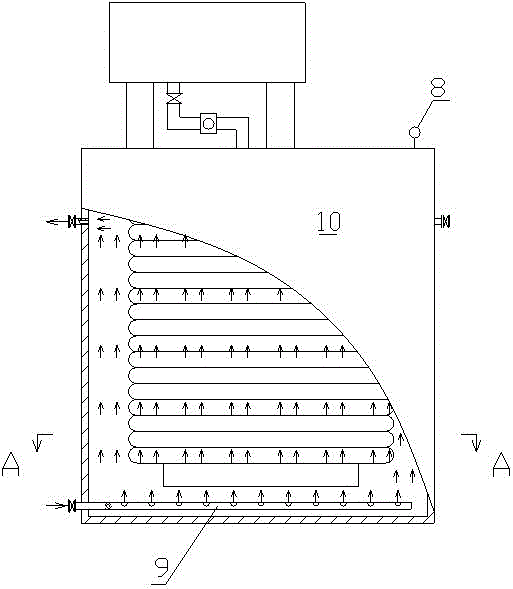

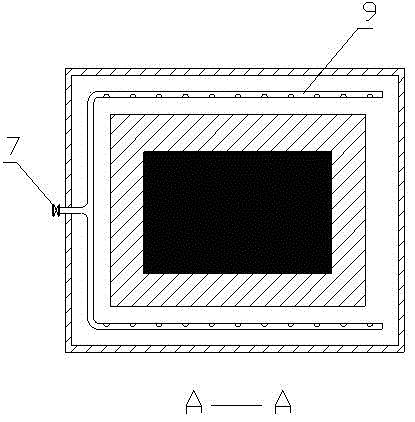

[0020] Such as Figure 1~5 Shown is a main transformer oil flow guide microcirculation device, including a frequency conversion microcirculation pump 6, a winding installed in the main transformer body 10, oil flow guide nozzles 9 on both sides of the bottom of the iron core, and an outlet on the upper part of the main transformer body. Oil valve 1, oil inlet valve 7 at the lower part of the main transformer body, transformer oil, oil flow connecting pipe outside the main transformer body, radiator 3, online oil temperature detector 8 and control module.

[0021] The oil flow guiding microcirculation device of the main transformer includes a variable frequency microcirculation pump 6, which pumps the cold oil flow into the main transformer body. The oil outlet valve 1 on the upper part of the main transformer flows into the radiator 3. After the oil flow is cooled in the radiator 3, it is pumped into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com