Positive-locking clutch

A technology of clutches and mating teeth, which is applied in the direction of clutches, magnetic drive clutches, non-mechanical drive clutches, etc., to achieve the effect of simplifying opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

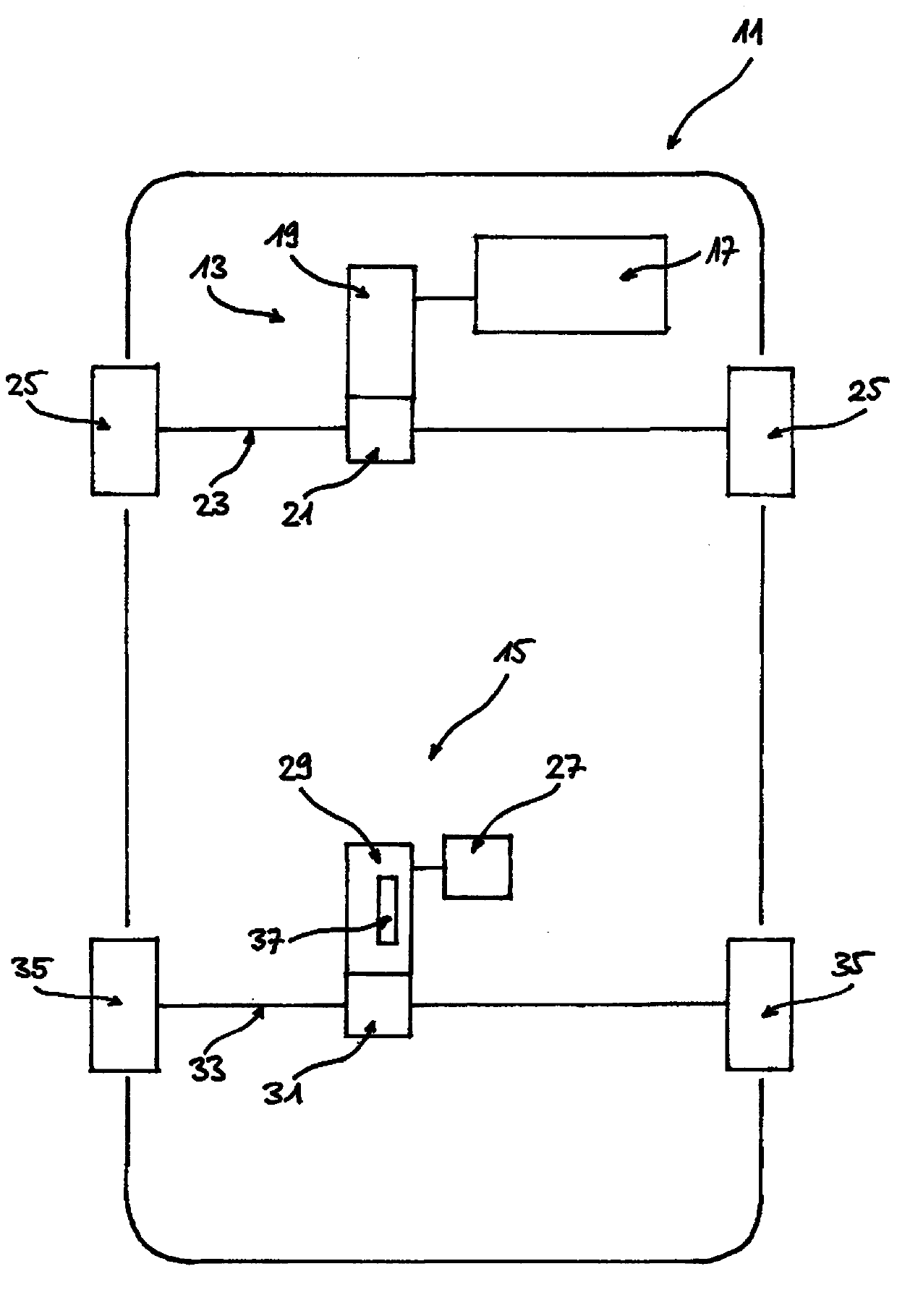

[0037] exist figure 1 The motor vehicle 11 is shown in a schematic illustration. The motor vehicle 11 has two drive trains 13 , 15 , one of which 13 has an internal combustion engine 17 as drive, which drives an axle with wheels 25 via a transmission 19 and an axle differential 21 twenty three. In the embodiment shown here, the axle 23 is the front axle of the motor vehicle 11 . The other drive train 15 includes an electric motor 27 as drive, which is connected to an intermediate transmission 29 . The intermediate transmission 29 is connected on the output side to an axle differential 31 which forms the main transmission for the drive train 15 and can transmit torque to the axle 33 and to the wheels 35 . Furthermore, a clutch 37 is provided in the intermediate transmission 29 .

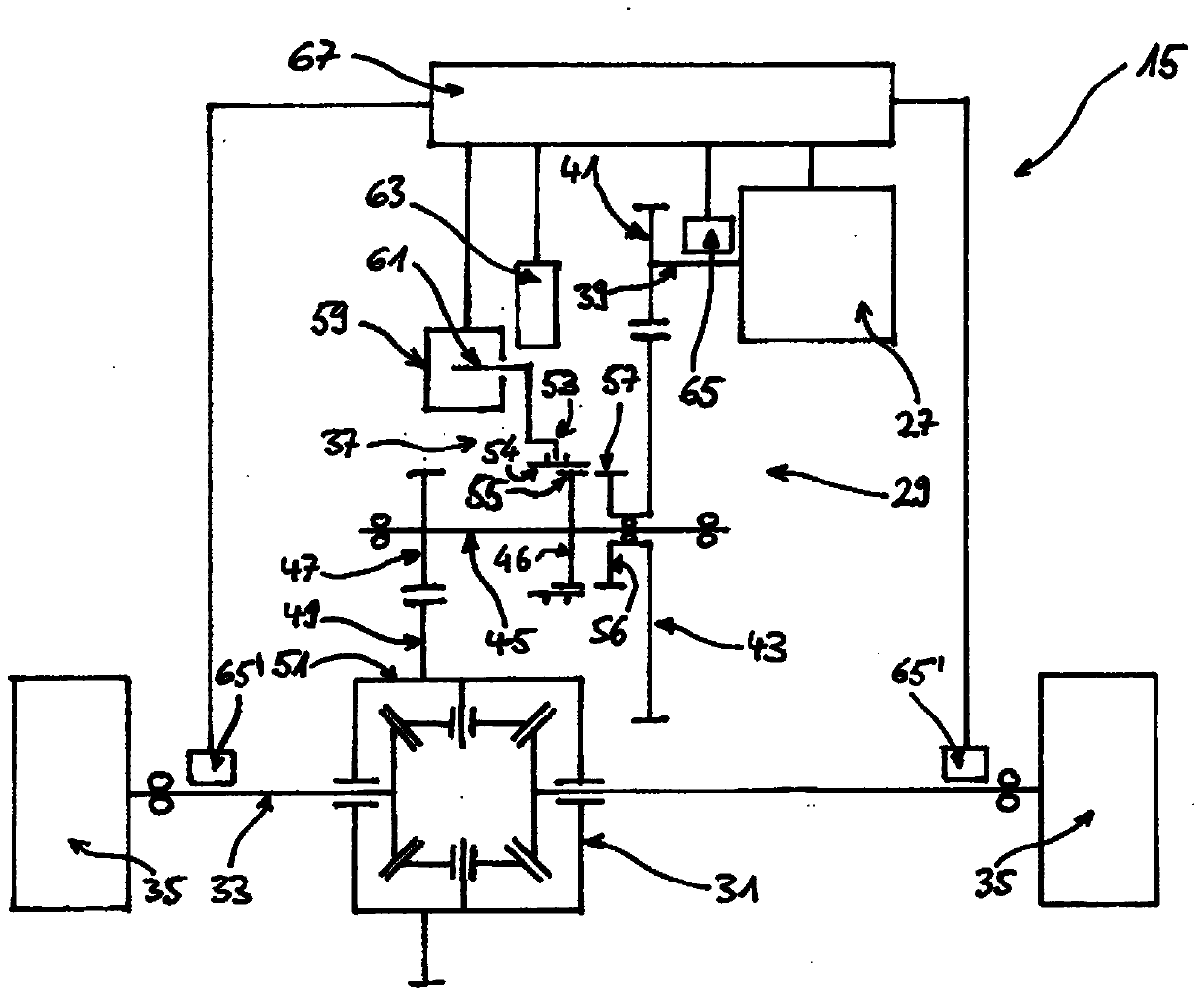

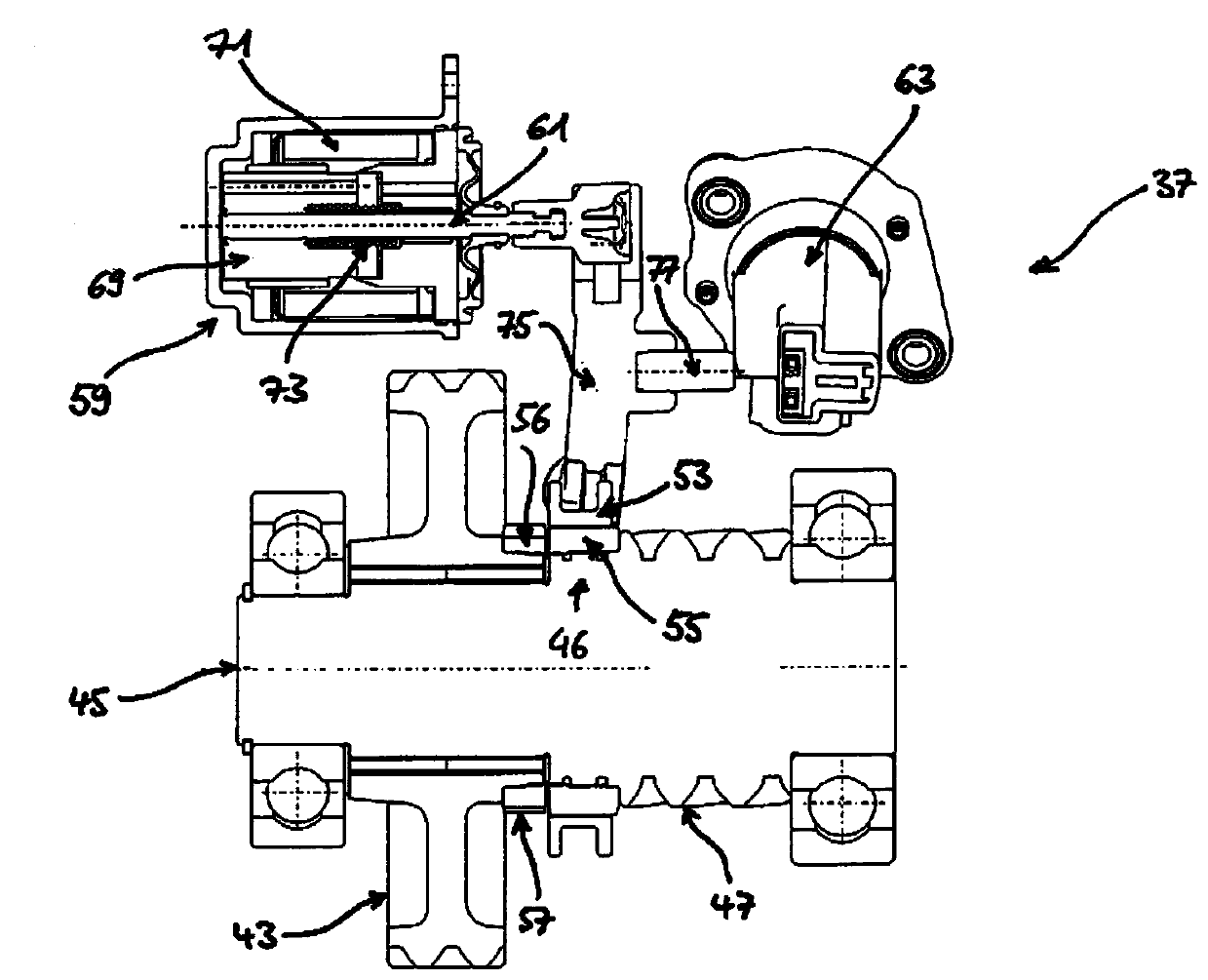

[0038] figure 2 The schematic illustration in FIG. 3 shows drive train 15 with electric motor 27 , intermediate transmission 29 and a main transmission designed as axle differential 31 . The wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com