Elliptical tube series tube expansion method

A tube expansion method and elliptical tube technology, applied in metal processing, heat exchange equipment, metal processing equipment, etc., can solve the problems of diagonal deviation, copper waste, low efficiency, etc., to reduce time waste, high efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

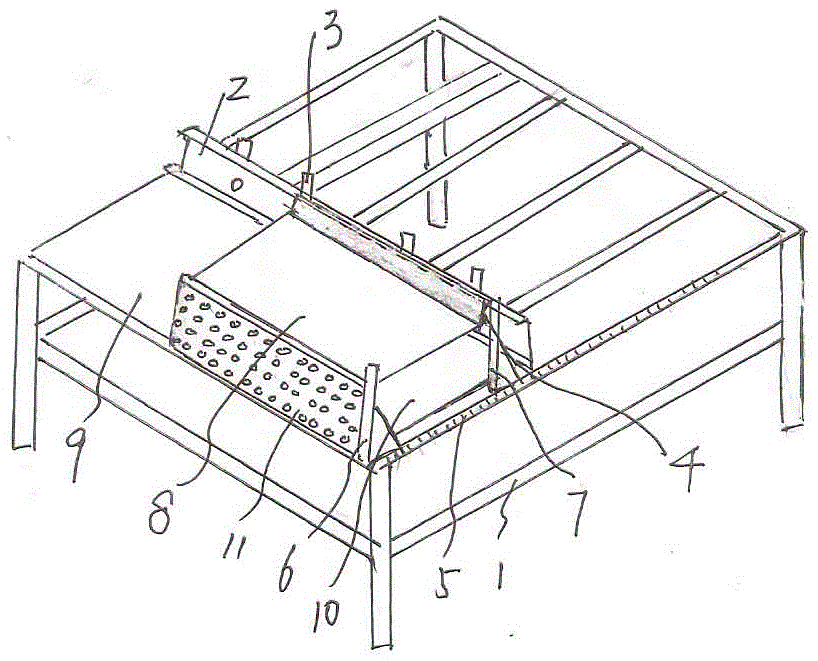

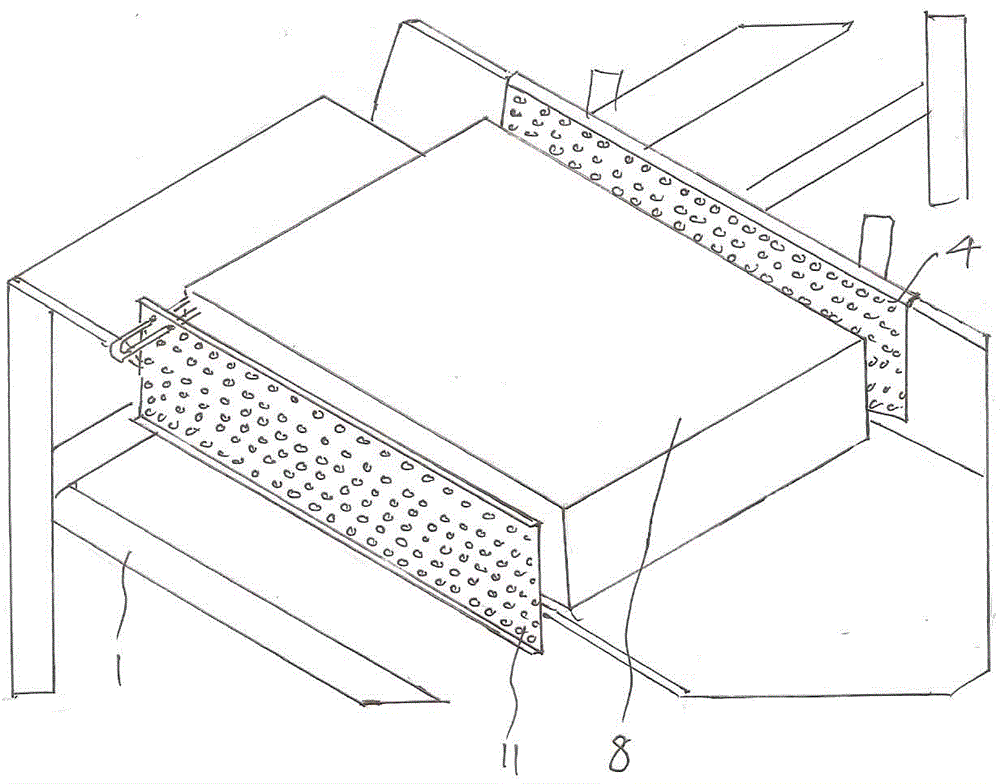

[0014] A method for expanding elliptical tubes in series, which is carried out by using a device for expanding elliptical tubes in series. The device for expanding elliptical tubes in series includes a workbench 1, on which a baffle 2 is arranged, and the baffle is fixed on the left and right On the movable baffle bracket 3, the side of the baffle facing the fin is in a concave shape protruding from the upper and lower ends, and the inner end plate 4 of the fin is hung; The frame is provided with a fixed bracket 6 and a sliding bracket 7 for positioning and fixing the fins. The fixed bracket is fixed at one end of the workbench, and the sliding bracket is close to the baffle. The backing plate 9 is laid on the position where the fins 8 are placed, and a blocking piece 10 is abutted on the fixed bracket and the sliding bracket, and is located between the fixed bracket, the sliding bracket and the fins.

[0015] When in use: According to the requirements of the processing drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com