Side current collector with double four-bar linkage in series

A four-bar linkage mechanism and lateral current receiving technology, applied in the field of current receivers, can solve the problems of the current receiving slipper jumping and arcing, adapting to small expansion and contraction range, unstable train receiving current, etc., and achieving reliable current receiving. The effect of high performance, flexible structure and layout, and large extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

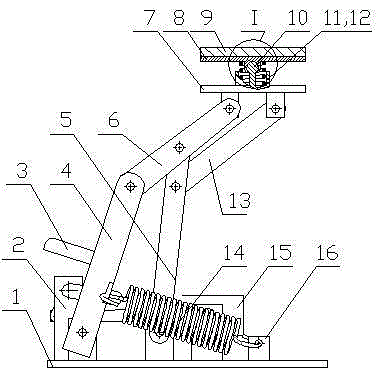

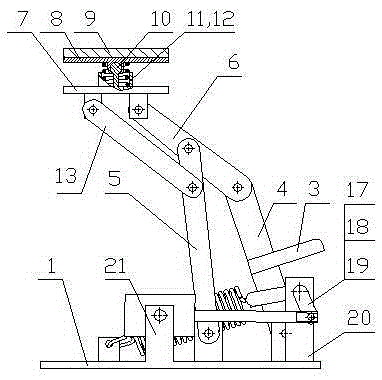

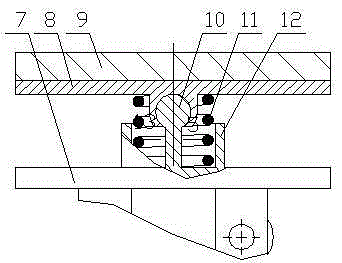

[0043] It is mainly composed of a base 1, a drive locking mechanism 2, a flow-collecting shoe 9, a shoe seat 7 and a swing mechanism. The swing mechanism is connected between the base 1 and the shoe seat 7, the driving locking mechanism 2 is installed between the base 1 and the bottom of the swing mechanism, and the flow collector shoe 9 is installed on the side of the shoe seat 7 facing away from the swing mechanism . The swing mechanism includes the main swing rod 4, the upper support rod 6, the lower link 5 and the upper link 13; the base 1, the main swing rod 4, the lower half of the upper support rod 6 and the lower link 5 are hinged to form the bottom four links Mechanism; the upper half of the upper support rod 6, the shoe seat 7, the upper connecting rod 13 and the upper half of the lower connecting rod 5 are hinged to form a top four-bar linkage; the bottom four-bar linkage and the top four-bar linkage are connected in series Structure; three hinged holes are respect...

Embodiment 2

[0045] It is basically the same as Embodiment 1, the difference is that the ball joint limit seat 12 is set outside the return spring 11, and the ball joint limit seat 12 and the fixed shaft of the ball joint 10 are installed on the sliding shoe seat 7 or the sliding shoe is installed at the same time. plate 8.

Embodiment 3、4

[0047] They are basically the same as Embodiments 1 and 2, but the difference is the structure of the driving locking mechanism 2: the driving locking mechanism 2 mainly includes a tension spring 14, a cylinder 15, a tension spring fixed support 16, a driving lever 3, and a bell crank , bellcrank support 20 and cylinder support 21; bellcrank support 20 and cylinder support 21 are all installed on the base 1; bellcrank is composed of driving wing plate 17, bellcrank rotating shaft 18 and stirring wing plate 19 to form rigid structure , installed on the bell crank support 20 through the crank crank shaft 18, the crank crank shaft 18 and the central axis of the toggle wing plate 19 form an included angle of 20-50 degrees; the cylinder 15 is hinged with the cylinder support 21; the drive wing plate 17 is hingedly connected with the main shaft of the cylinder 15, and the toggle wing 19 is adjacent to the main fork 4, and the driving lever 3 is installed on the main fork 4 above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com