Material conveying base of steel band rolling-up machine

A technology of winding machine and base, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of laborious and difficult unloading and transportation, and achieve the effect of simple structure and convenient transportation and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

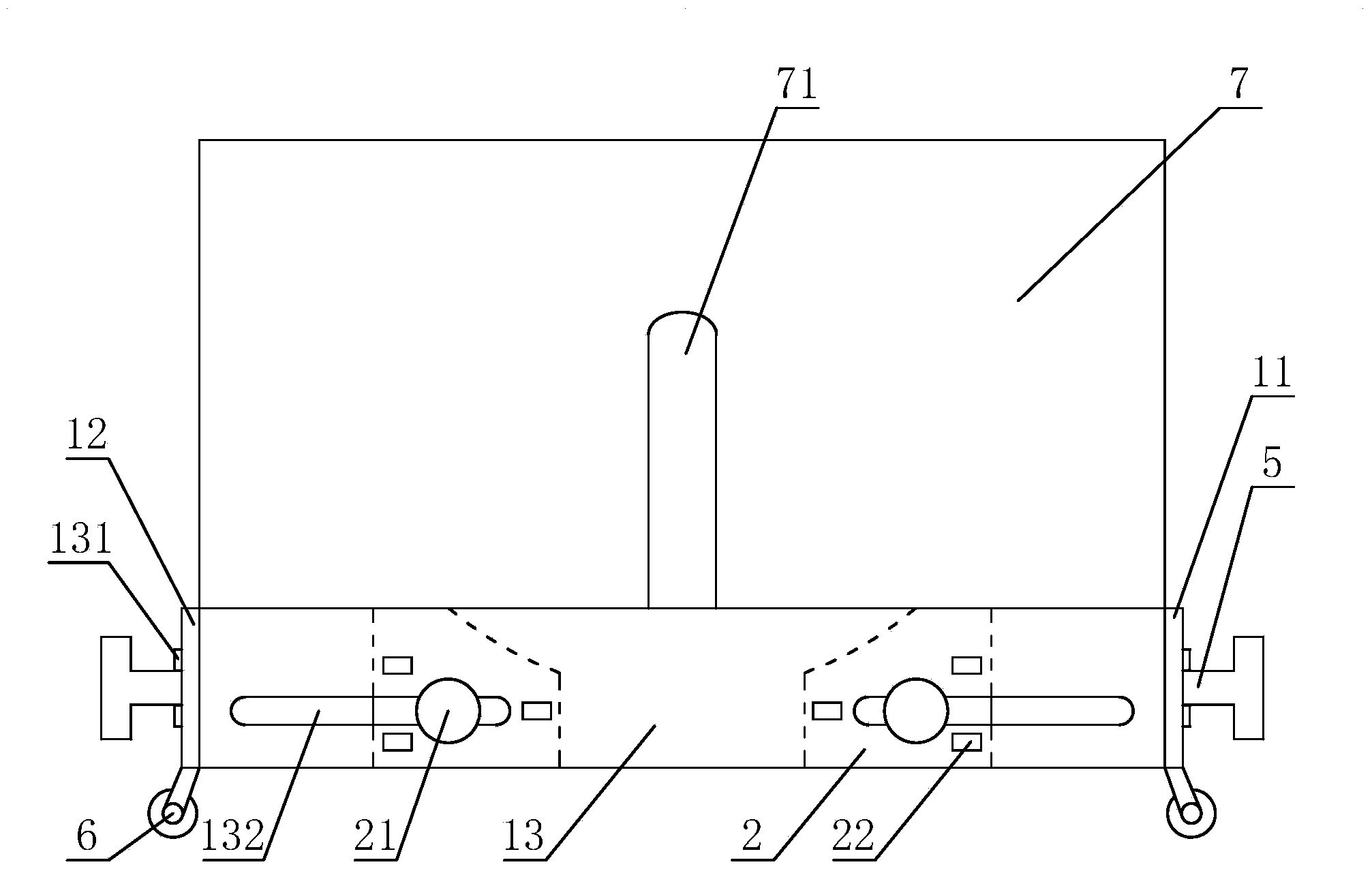

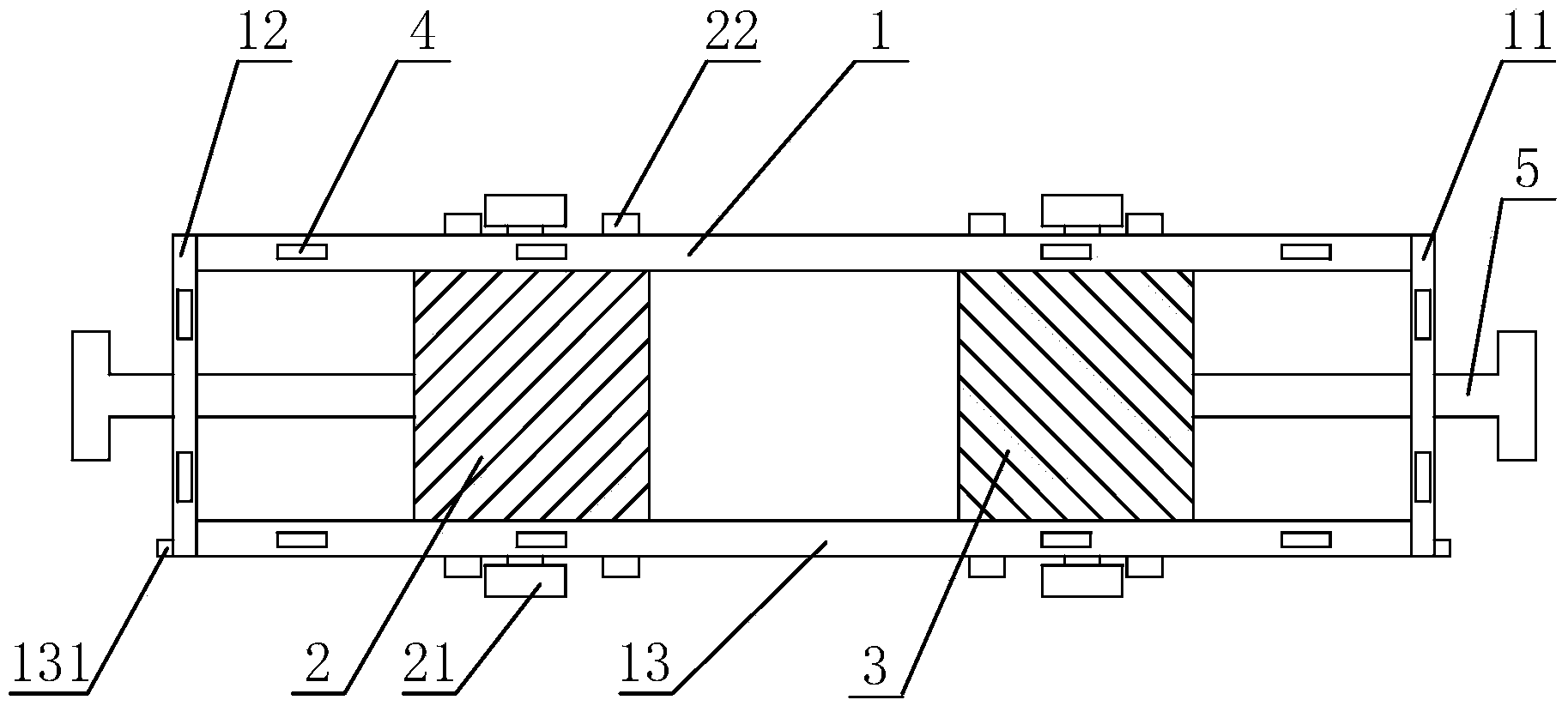

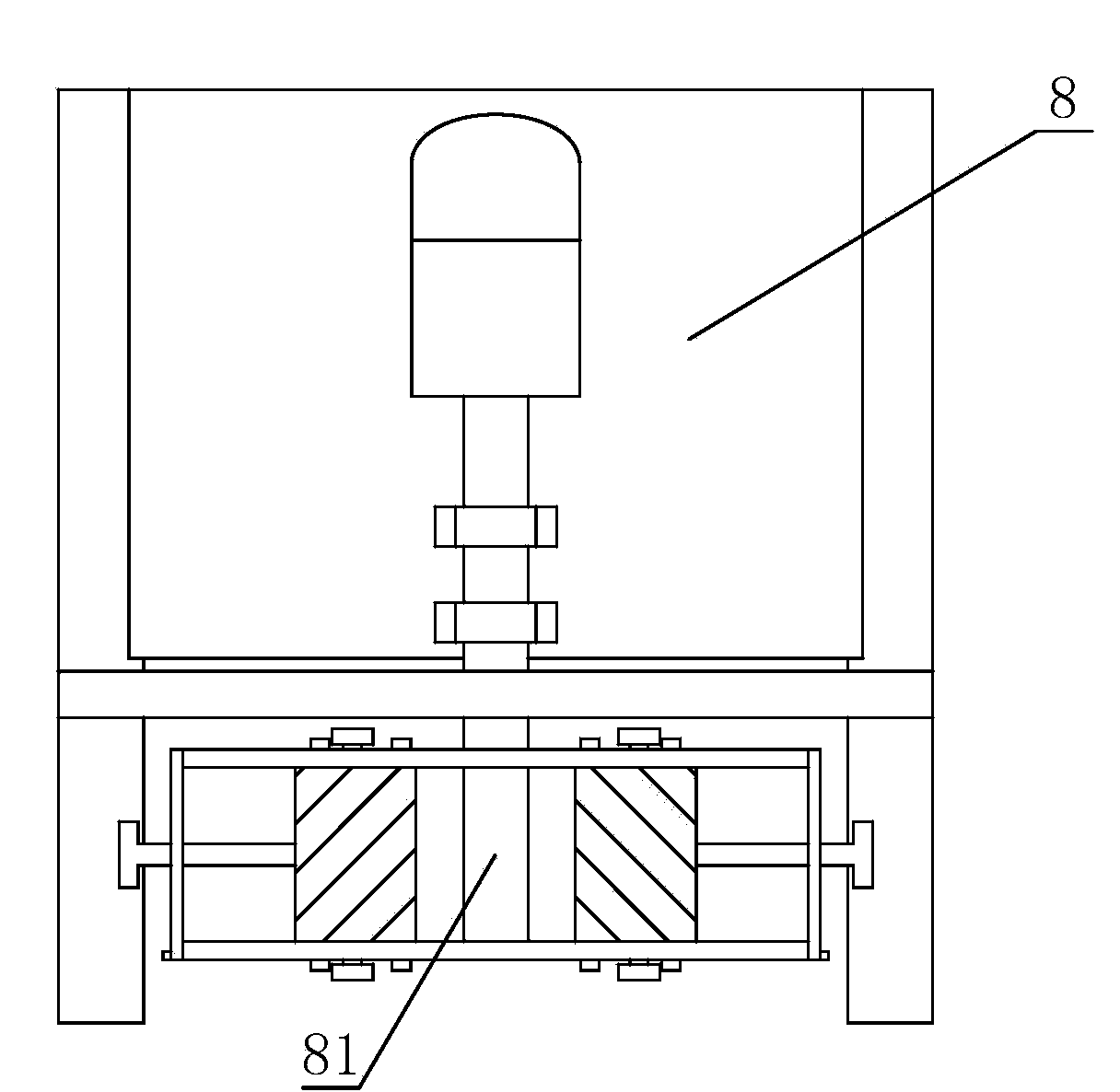

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] Such as Figure 1 to Figure 4 As shown, the material transport base of the steel strip winder includes the surrounding side plates, the left positioning block 2, the right positioning block 3 and the baffles arranged on the surrounding side plates, the left side plate 12, the right side plate 11 is integrally fixedly connected with the rear side plate 1, a pair of protrusions 131 are provided on both sides of the front side plate 12, grooves are opened at corresponding positions on the left side plate 12 and the right side plate 11, and the protrusions 131 are stuck in the In the groove, the front side plate 13 is clamped and fixed with the left side plate 12 and the right side plate 11. There are slots 4 above the side plates, and the clamping block 72 provided below the baffle plate is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com