Shuttle cart

A technology of shuttle car and frame, applied in the field of shuttle car, can solve the problem of high cost and achieve the effect of low power, cost saving and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

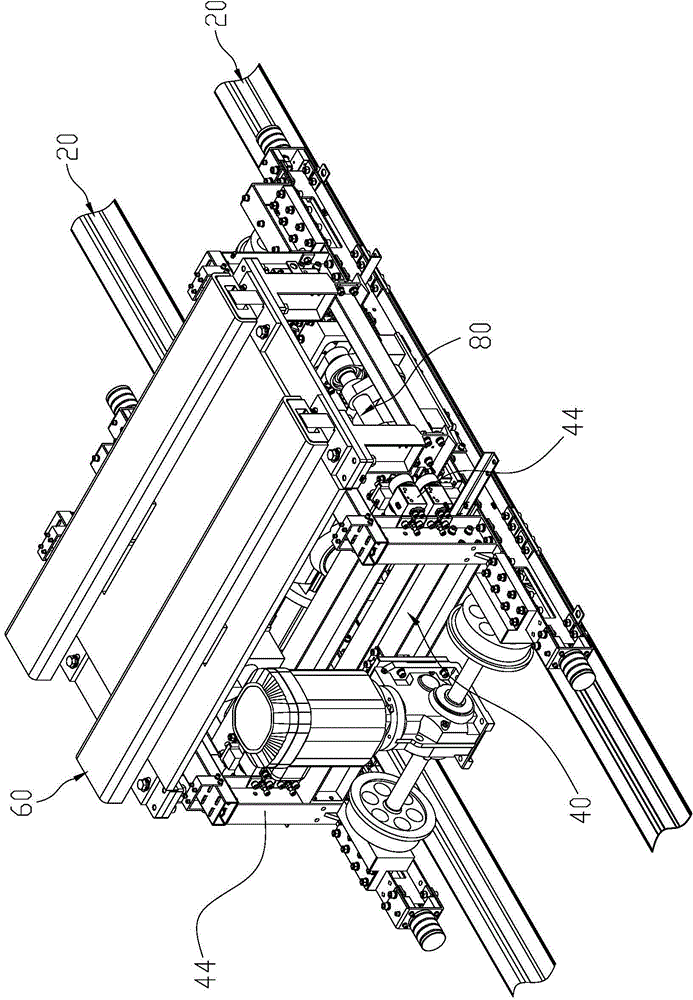

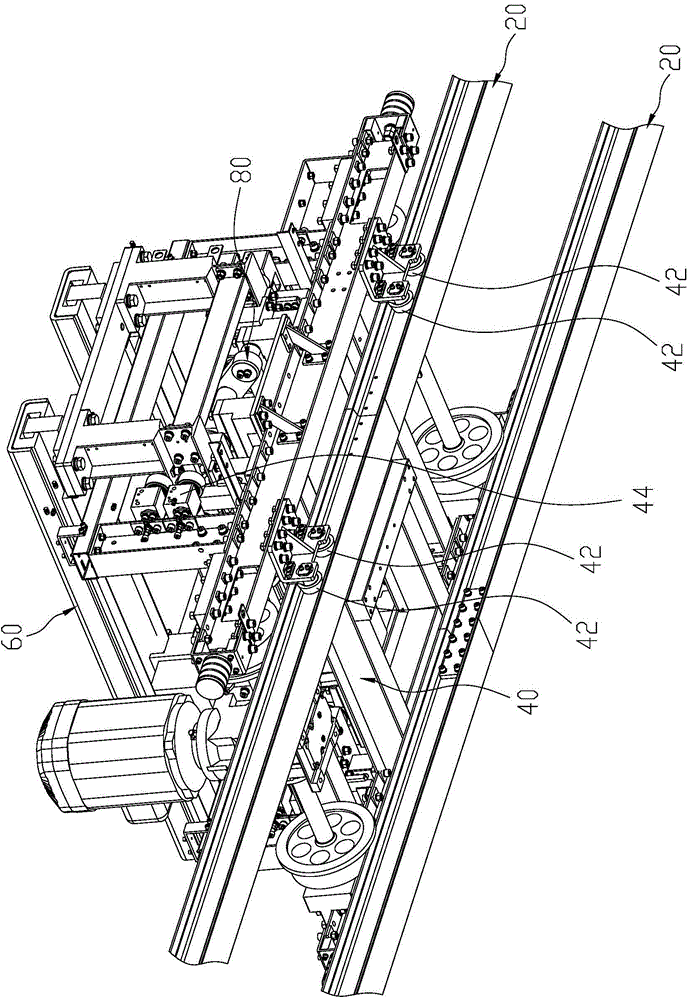

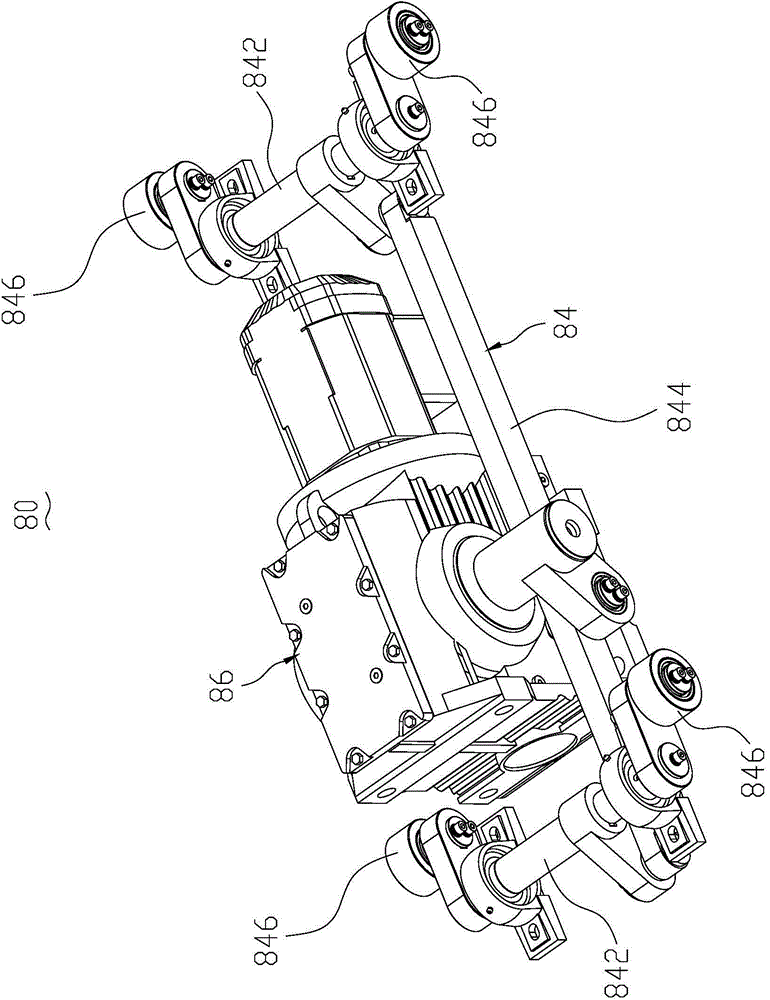

[0023] Please refer to figure 1 , a shuttle vehicle of the present invention is used for shifting the goods on the shelf. The shuttle car includes two guide rails 20 arranged in parallel at intervals, a vehicle frame 40 that can reciprocate along the guide rails 20 , is arranged on the vehicle frame 40 and can reciprocate and expand in a direction perpendicular to the moving direction of the vehicle frame 40 The fork 60 (such as Figure 6 shown), is arranged on the vehicle frame 40 and is used to drive the lifting device 80 of the pallet fork 60 to reciprocate in the vertical direction.

[0024] Please refer to figure 1 and figure 2 , the side of the guide rail 20 is provided with a strip-shaped groove 22 . The front end and the rear end of each side of the vehicle frame 40 are respectively provided with two pulleys 42 . The pulley 42 is slidably embedded in the groove 22 . The pulleys 42 clamp the two guide rails to prevent the vehicle frame 40 from tilting.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com