Silicone rubber environment-friendly and flame-retardant cable material used for rail locomotive vehicle

A technology for flame-retardant cable materials and rail locomotives, applied in the field of cable materials, can solve the problems of polluting the environment and hindering the timely escape of escape personnel, and achieves the effects of low smoke generation, good flame retardant performance, and excellent physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A silicone rubber flame-retardant cable material for rail vehicles, made of the following raw materials in parts by weight: methyl vinyl phenyl silicone rubber 55, bisphenol A polyarylate 45, vinyl tributylketoxime silane 2 , 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane 3, lignin phenolic resin 8, hydroxyapatite 10, sodium antimonate 6, calcium aluminate 8, hexamethyl Disilazane 4, diphenylsilanediol 3, wood tar 11, tris(trimethylsilane) phosphite 16, pentaerythritol tetraisocaprylate 12, spray carbon black 22, benzyl silicone oil 4, oxidation Polyethylene wax 6, zinc stearate 2.5, modified stone powder 16, N-(4-anilinophenyl)methacrylamide 2, N,N'-di-n-butylthiourea 1.5;

[0013] The preparation method of the modified stone powder is as follows: (1) Weigh coke gemstones, volcanic stones, and attapulgite at a weight ratio of 6:4:2, mix them uniformly, calcinate at 750°C for 2 hours, cool naturally to room temperature, pulverize, and sieve , stand-by; (2) getting the...

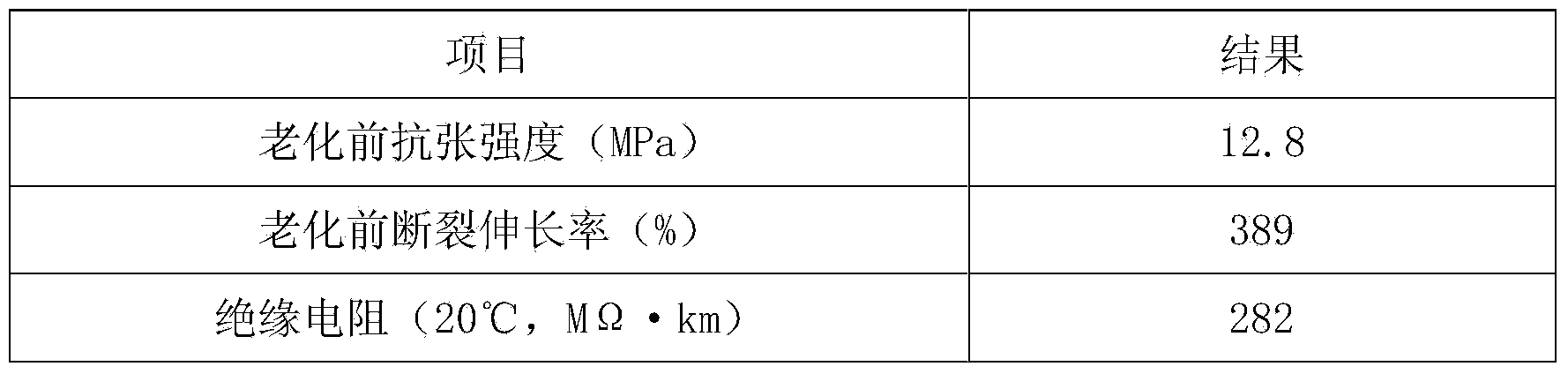

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com