Lifting and supporting device used for loader

A support device and loader technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of unfavorable inclined picking and placing materials, poor stability, long rocker arm, etc., to facilitate bucket operation and improve stability , the effect of shortening the arm length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

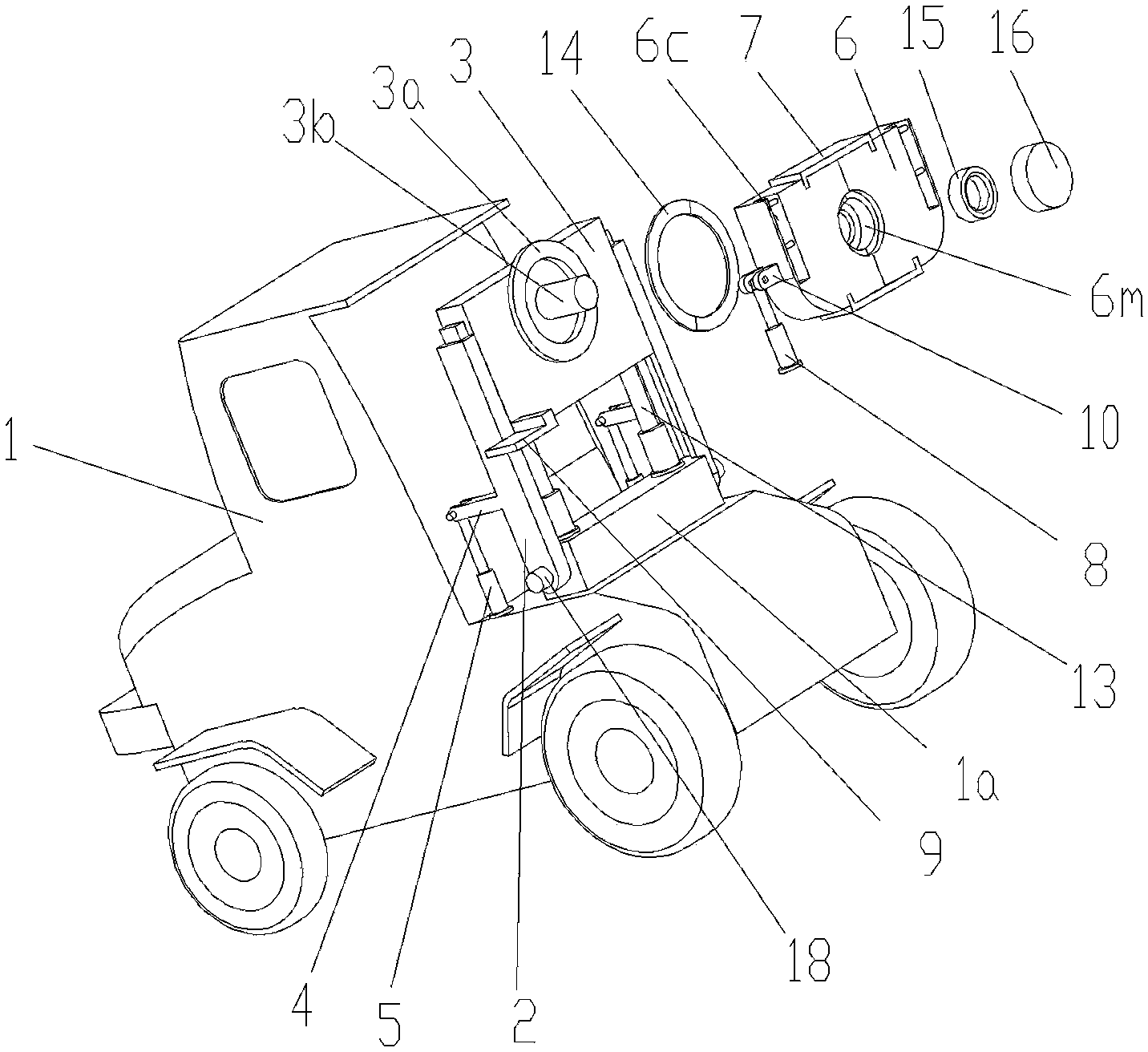

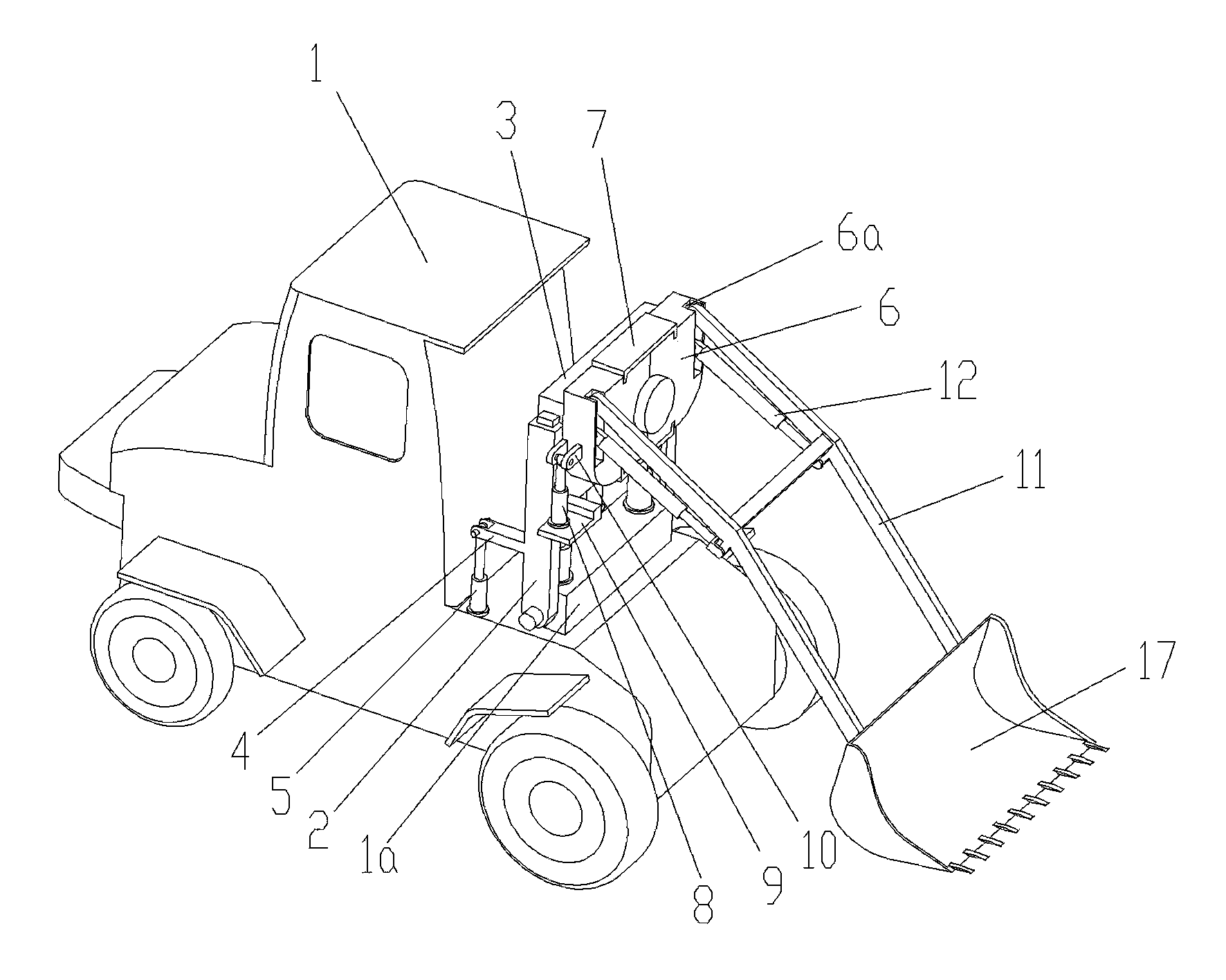

[0016] like figure 1 and figure 2 As shown, a lifting support device for a loader provided by the present invention includes a car body 1, a rocker arm 11 is connected to the car body 1, and a bucket 17 is connected to the front end of the rocker arm 11. It is characterized in that:

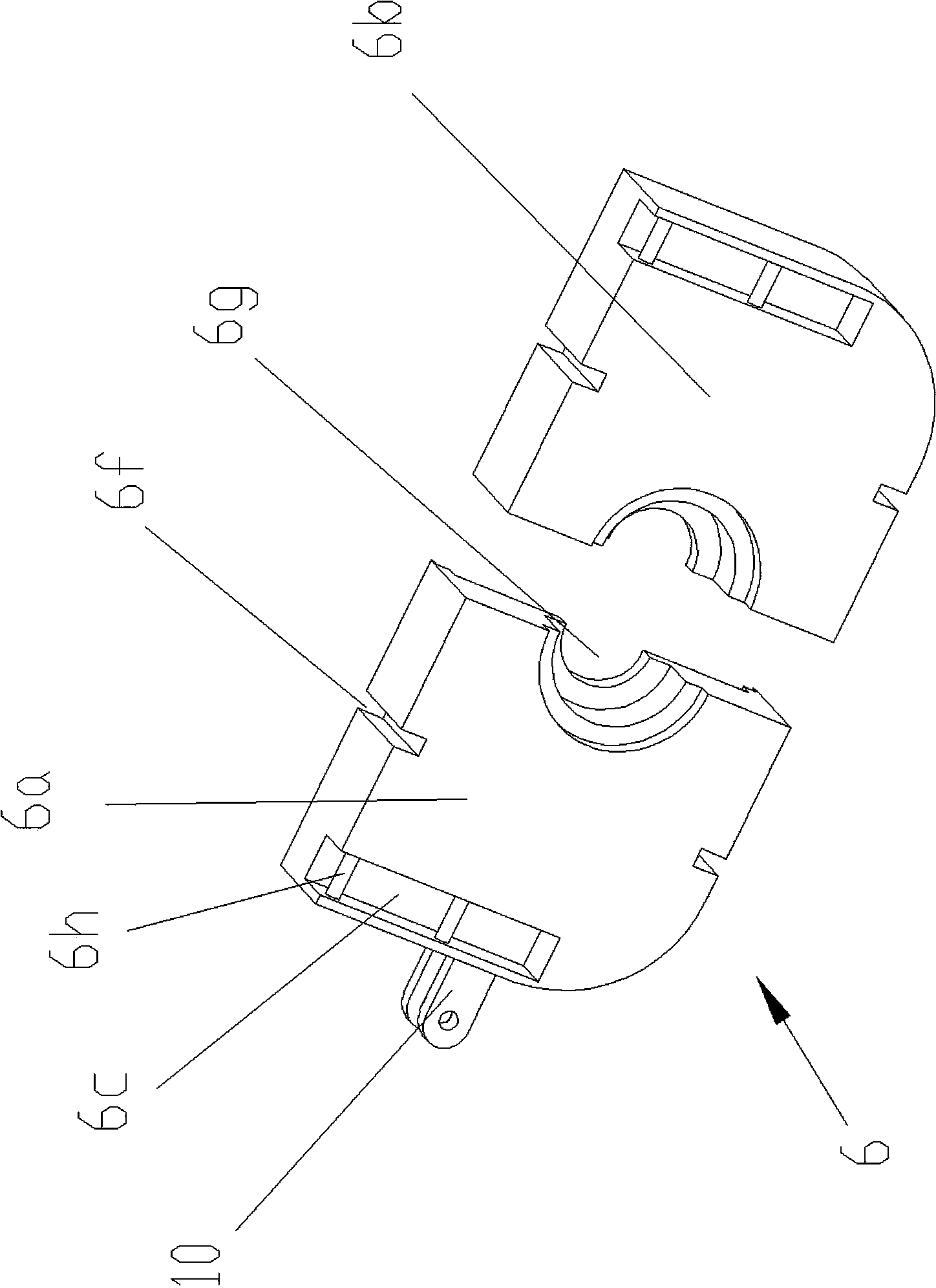

[0017] The front side of the vehicle body 1 is provided with a support block 1a, and a hinge shaft 18 is arranged symmetrically on both sides of the support block 1a, and each hinge shaft 18 is hingedly matched with a slide rail 2, and the slide rail 2 of the slide rail 2 One end of the seat is hinged on the hinge shaft 18, and a rectangular lifting plate 3 is connected between the sliders of the two slide rails 2, and two first oil cylinders are installed under the lifting plate 3. 13 is supported and fixed on the vehicle body 1, the piston rods of the first oil cylinder 13 are hingedly matched with the lifting plate, and the bases of the two first oil cylinders 13 are connected and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com