A logistics warehouse automatic unloading and palletizing method

An automatic unloading and stacking technology, applied in the field of warehousing and logistics, can solve the problems of inability to grasp the storage time and intelligent scheduling in real time, difficulty in grabbing containers, and no traceability, so as to achieve free and flexible operation and reduce purchase costs. , the effect of reducing arm length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

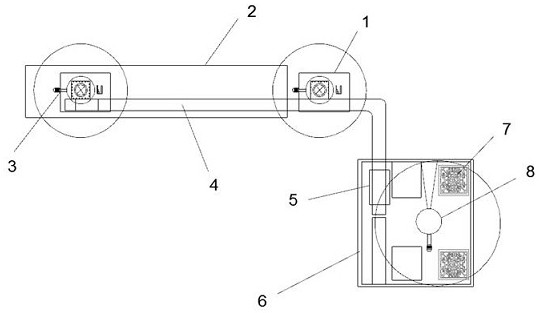

[0031] A method for automatically unloading and palletizing a logistics warehouse, comprising the steps of:

[0032] In the first step, the logistics vehicle stops in place, the container door is manually opened, and the extension plate is erected obliquely between the container 2 and the ground;

[0033] In the second step, the manual remote control crawler vehicle 1 runs to the door of the container and is kept parallel to the container. The crawler vehicle is equipped with a robot 4 and a robot 3 with a robot visual recognition system;

[0034] In the third step, the robot recognizes the layer height, column number and box size of the cartons in the container through the robot visual recognition system, addresses the boxes in the container, and then grabs 2-4 cartons in the container at a time and puts them on the telescopic transportation line , and transmit the information to the CPU. After each row of boxes is grabbed, the CPU controls the tracked vehicle to move a dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com