Shock-absorbing torsion transmission device and double-wheel milling machine

A torque transmission and milling technology, which is applied in earth movers/excavators, construction, etc., can solve the problems of transmission parts of easily damaged milling parts, small transmission force and torque, large coupling size, etc., to achieve good size, High force and torque transmission capacity, effect of utilization of construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

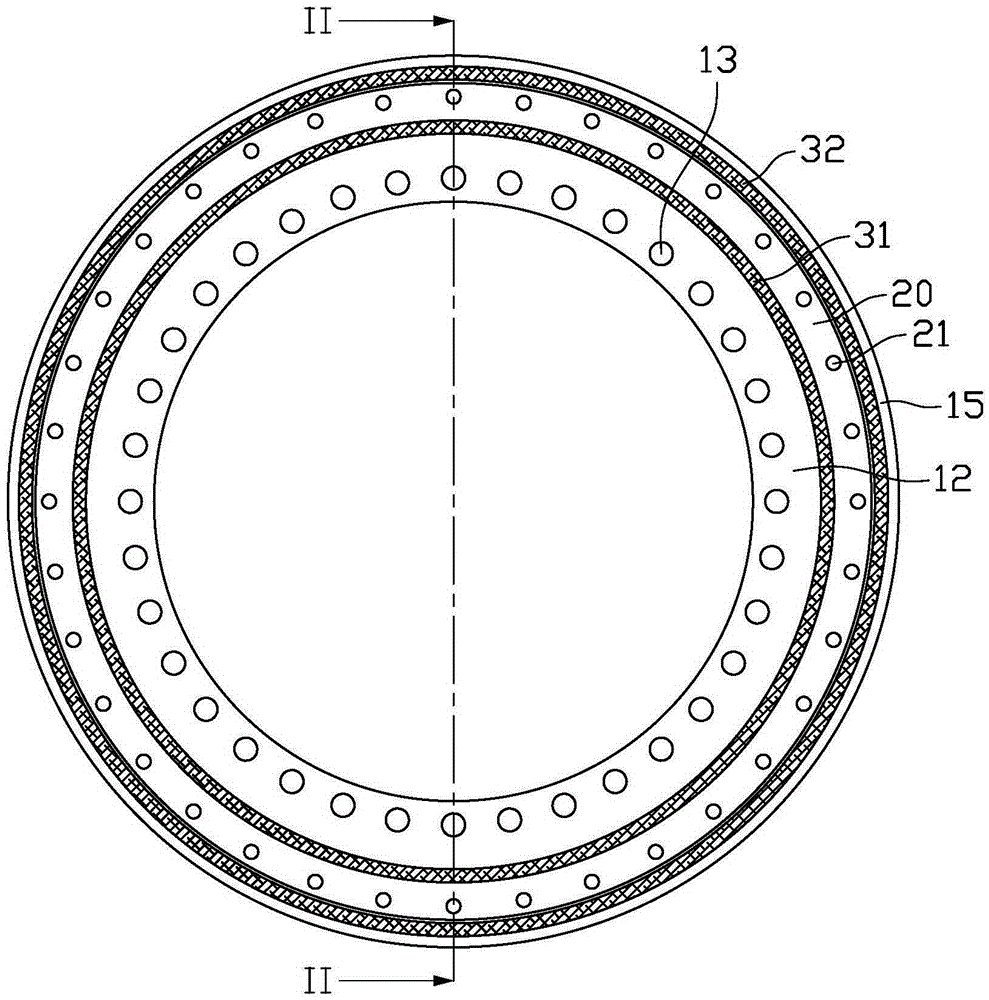

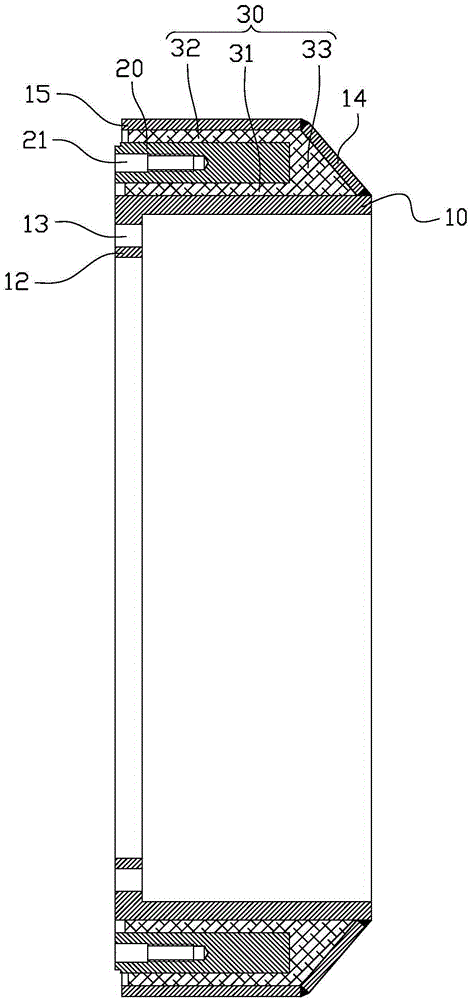

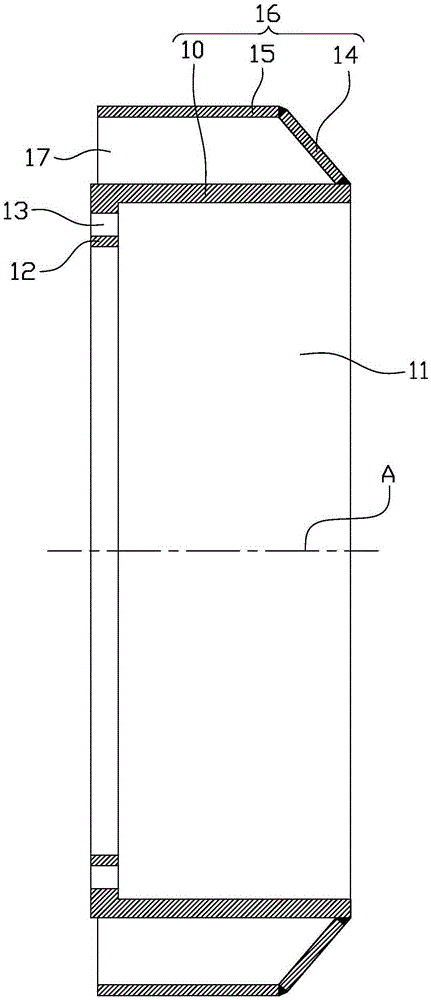

[0029] figure 1 It is a schematic front view of the shock absorbing torsion transmission device according to the first embodiment of the present invention, figure 2 yes figure 1 A schematic sectional view along line II-II, image 3 yes figure 1 Schematic diagram of the structure of the input ring in the shock-absorbing torsion transmission device, Figure 4 yes figure 1 The structural diagram of the output ring in the shock-absorbing torsion transmission device, please also refer to Figure 1 to Figure 4 , the shock absorbing torsion transmission device is used to be arranged on the transmission output part 40 ( Figure 5 and Figure 6 ) and milling wheel 50 ( Figure 5 and Figure 6 ) to damp and transmit torque, the shock absorbing torsion tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com