Air compressor gas storage tank automatic water draining device

A technology of automatic drainage and gas storage tank, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of inconvenient management, heavy labor, cumbersome operation, etc., and achieve tedious operation and management inconvenience, The effect of liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

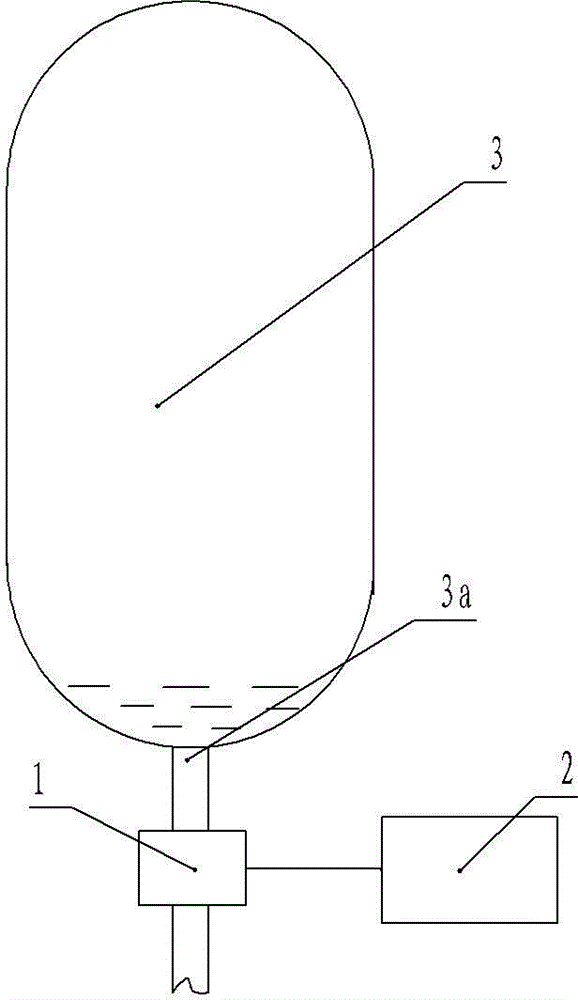

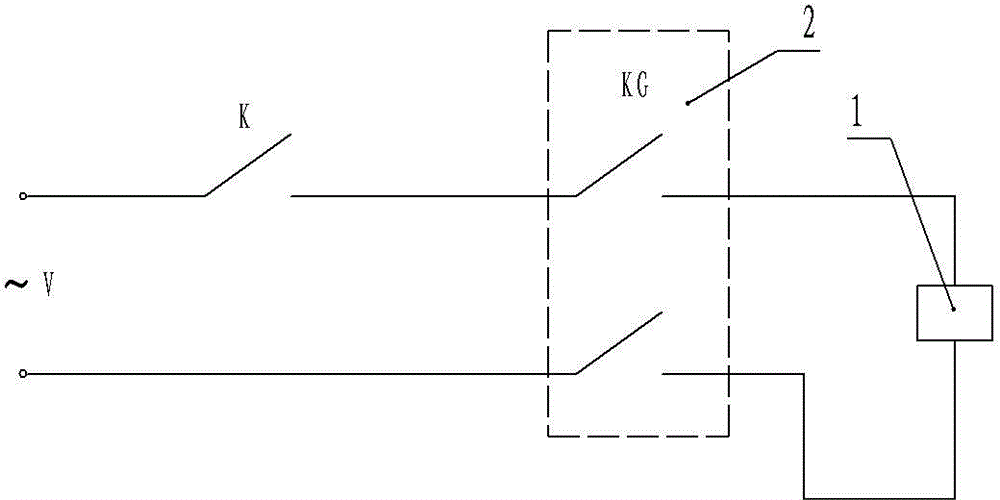

[0012] figure 1 , figure 2 The air compressor air storage tank automatic drainage device shown includes an air storage tank 3 with a water outlet 3a, an AC solenoid valve 1 is arranged on the pipeline of the air storage tank 3 water outlet 3a, and the valve control end of the AC solenoid valve 1 The terminal corresponding to the time control switch 2 is connected, and the time control switch 2 is connected to the power supply through the power switch k.

[0013] The present invention installs a solenoid valve at the water outlet end of the air compressor gas storage tank, and uses a time control switch to control the solenoid valve. By programming the time control switch, the time and time interval of its output power are controlled to control the action of the solenoid valve. Time and time interval, to automatically control the automatic drainage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com