Comprehensive gear-shifting mechanism of all-terrain vehicle

A technology for all-terrain vehicles, shifting mechanisms, applied to mechanical equipment, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

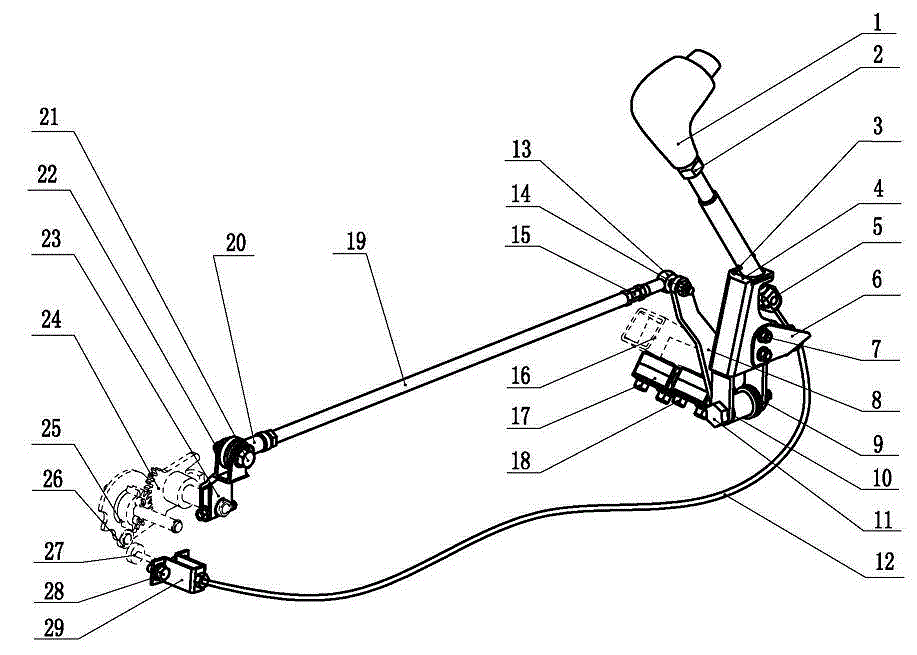

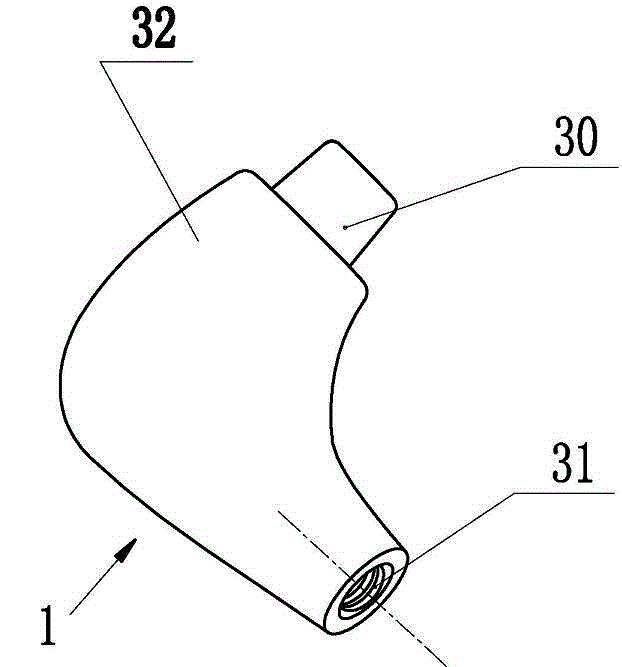

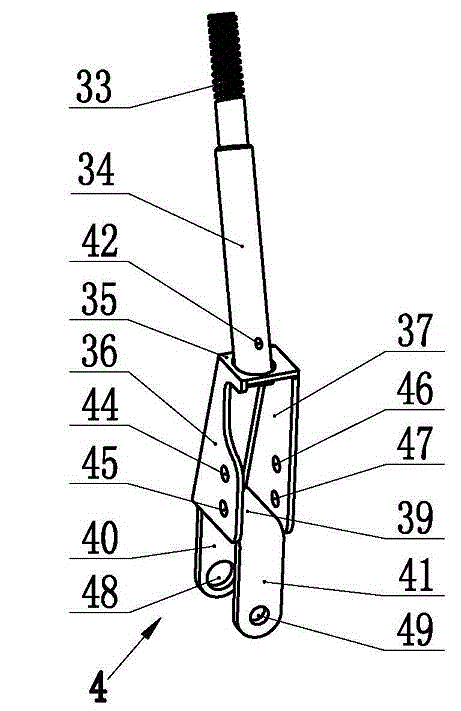

[0052] see figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 19 , Figure 21 , Figure 22 , Figure 23 , Figure 25 and Figure 26 , the all-terrain vehicle comprehensive shift mechanism, which is mainly composed of handle head 1, cable suspension rod limit screw 3, welding assembly 4, cable suspension rod 5, cable front mounting plate 6, cable front mounting plate fixing bolts 7. Shift lever shaft 8, torsion spring 9, plastic spacer 10, shift lever bolt 11, cable 12, ball joint 13, parallel nut 14, stud bolt 15, rotating shaft fixing sleeve 17, rotating shaft The fixed sleeve bolt 18, the pull rod 19, the ball head assembly 20, the ball head assembly rocker arm connecting bolt 21 and the rocker arm 23 are composed of the handle head of the welded assembly 4 connected to the handle head mounting threaded hole 31 of the handle head 1. The lower end of the hollow screw 33 is connected to the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com