Optical fiber micro-bending sensor with serialized cushion structure

A microbend sensor and optical fiber technology, which is applied in the direction of measuring the change of optical properties of materials when they are stressed, can solve the problems of small measurement range and optical fiber damage, and achieve the purpose of preventing additional bending of optical fibers, stable loading, and resistance to fiber. The effect of strong interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

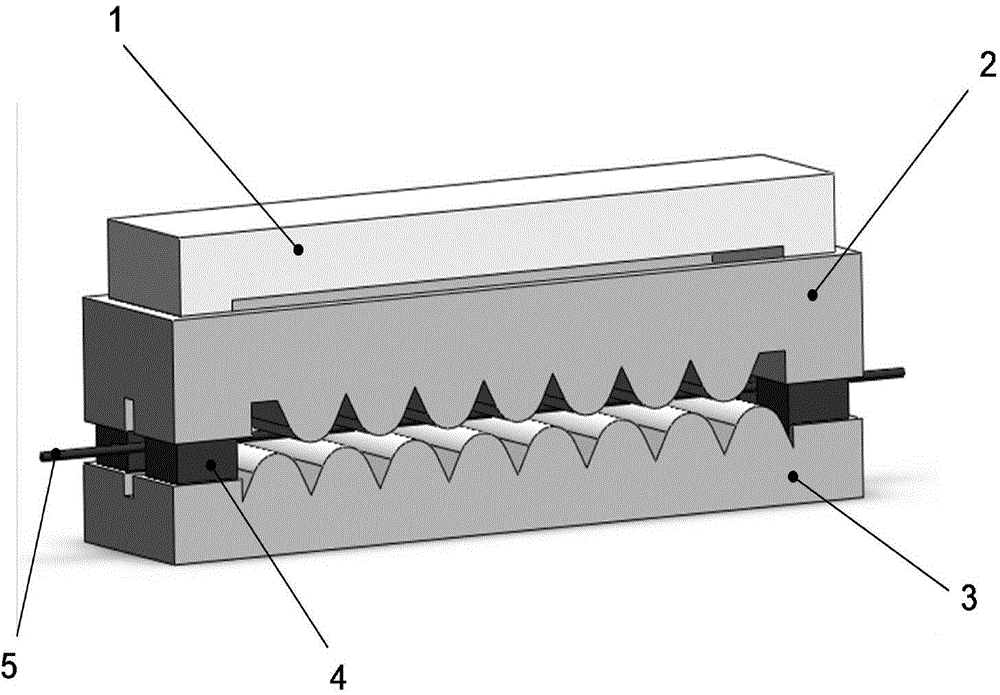

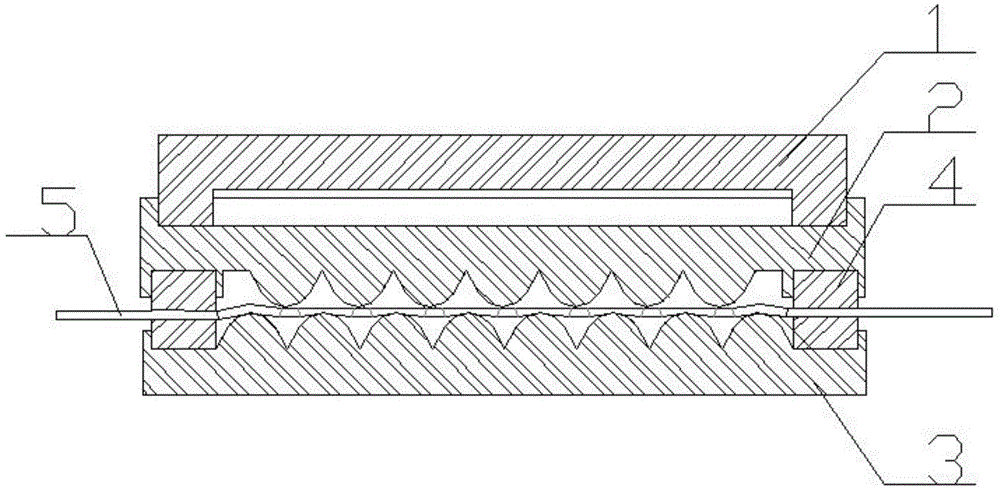

[0015] Specific implementation mode one: as figure 1 , figure 2 As shown, the serialized cushion structure optical fiber microbend sensor of the present embodiment includes a loading bridge 1, an upper toothed plate 2, a lower toothed plate 3, four pads 4 and an optical fiber 5; the upper toothed plate 2 There is a reserved groove on the upper end surface, and the lower end surface of the loading bridge 1 is set in the reserved groove; the lower end surface of the upper toothed plate 2 is provided with seven upper teeth with a semicircular cross-section along the length direction. The lower end surfaces of the four corners of the upper toothed plate 2 are respectively provided with square protrusions, and an optical fiber channel is arranged between the two square protrusions on the same side in the width direction, and on the lower end surfaces of the four corners of the square protrusions All have square grooves; the upper end surface of the lower toothed plate 3 is provid...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the loading bridge 1 is made of LY12 superhard aluminum alloy. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the upper toothed plate 2 is processed by LY12 superhard aluminum alloy. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com