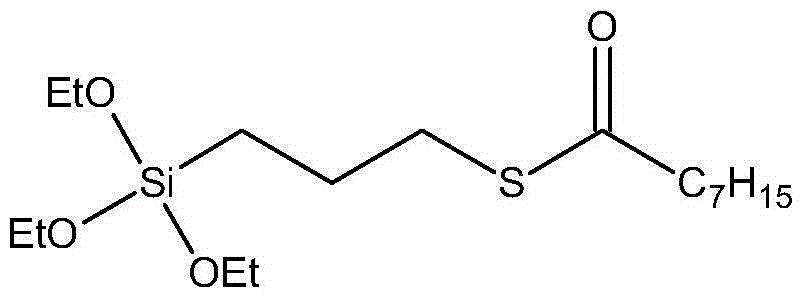

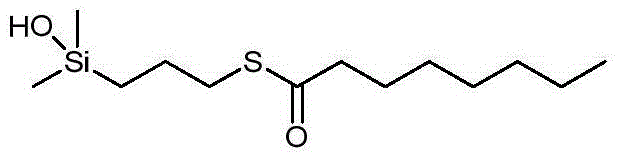

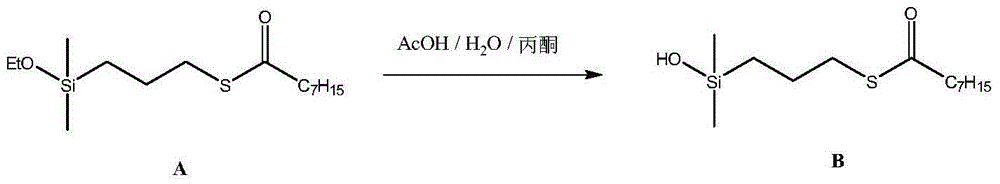

Rubber composition comprising a blocked mercaptosilane coupling agent

A rubber composition and a technology for the composition, which are applied in the field of inorganic filler-reinforced diene rubber compositions, can solve the problems of high viscosity, premature vulcanization, damage to processing characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] I. Measurements and Tests Used

[0028] The rubber compositions in which the coupling agents were tested were characterized before and after curing as described below.

[0029] I-1. Tensile test

[0030] These tensile tests make it possible to determine elastic stress and fracture properties. These tests were performed according to the French standard NF T46-002, September 1988, unless otherwise indicated. Nominal secant modulus (or apparent stress in MPa) at 100% elongation (denoted as M100) and at 300% elongation (M300) in the second elongation (i.e. at the measured after an adaptation cycle at the elongation rate).

[0031] I-2. Kinetic Properties

[0032] The kinetic properties ΔG* and tan(δ) were measured on a viscosity analyzer (Metravib VA4000) according to standard ASTM D5992-96 max . Samples of vulcanized compositions (thickness 4mm, cross-sectional area 400mm 2 The response of the cylindrical sample). A strain amplitude sweep was performed from 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com