Method for preparing carbonated fruit drink

A technology for beverages and juices, which is applied to gas-containing food ingredients, food ingredients as taste modifiers, food science, etc., can solve the problems of low temperature storage, poor taste at noon, short shelf life, etc., to avoid nutrient damage, fruit juice ingredients Stable, long flavor retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

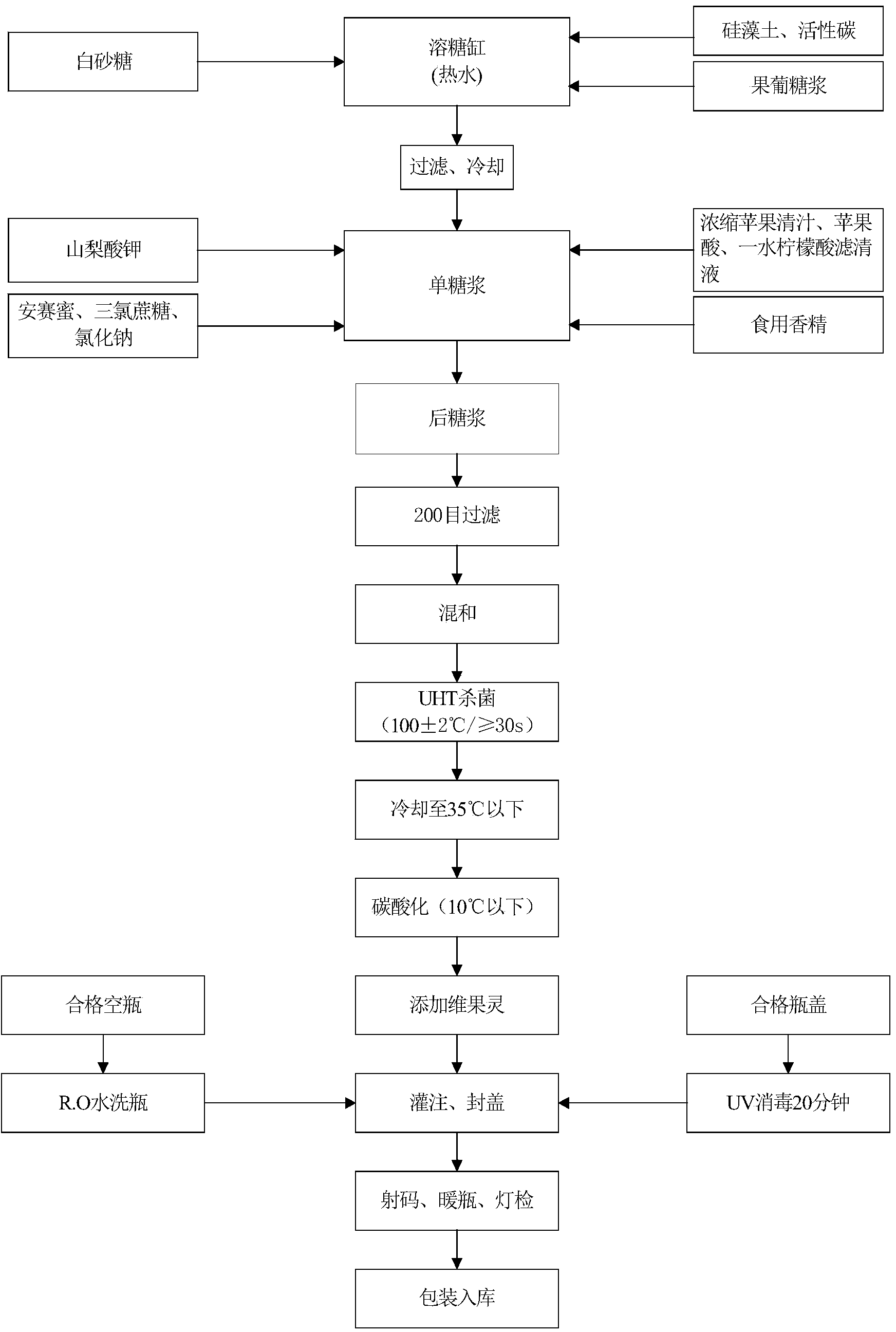

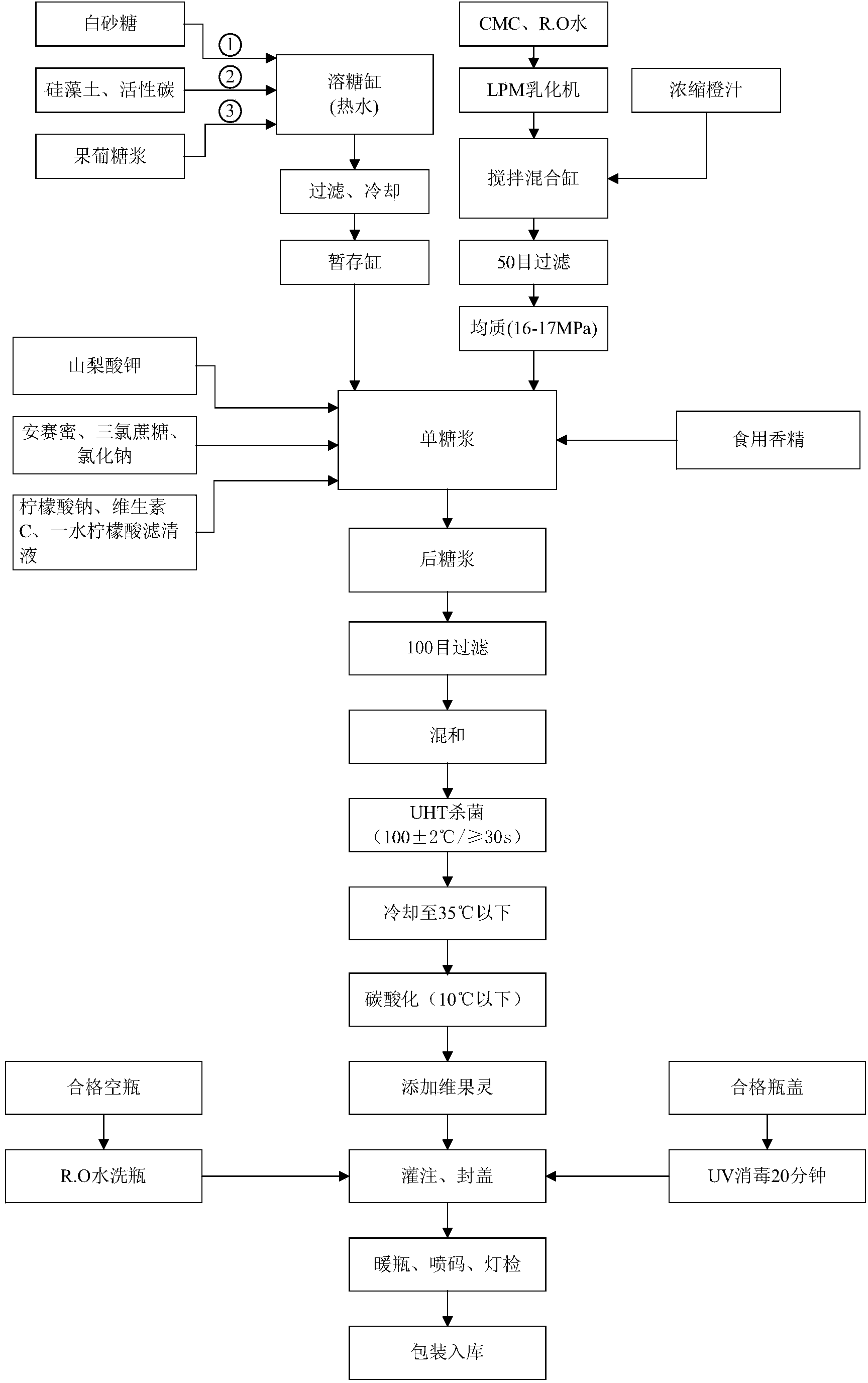

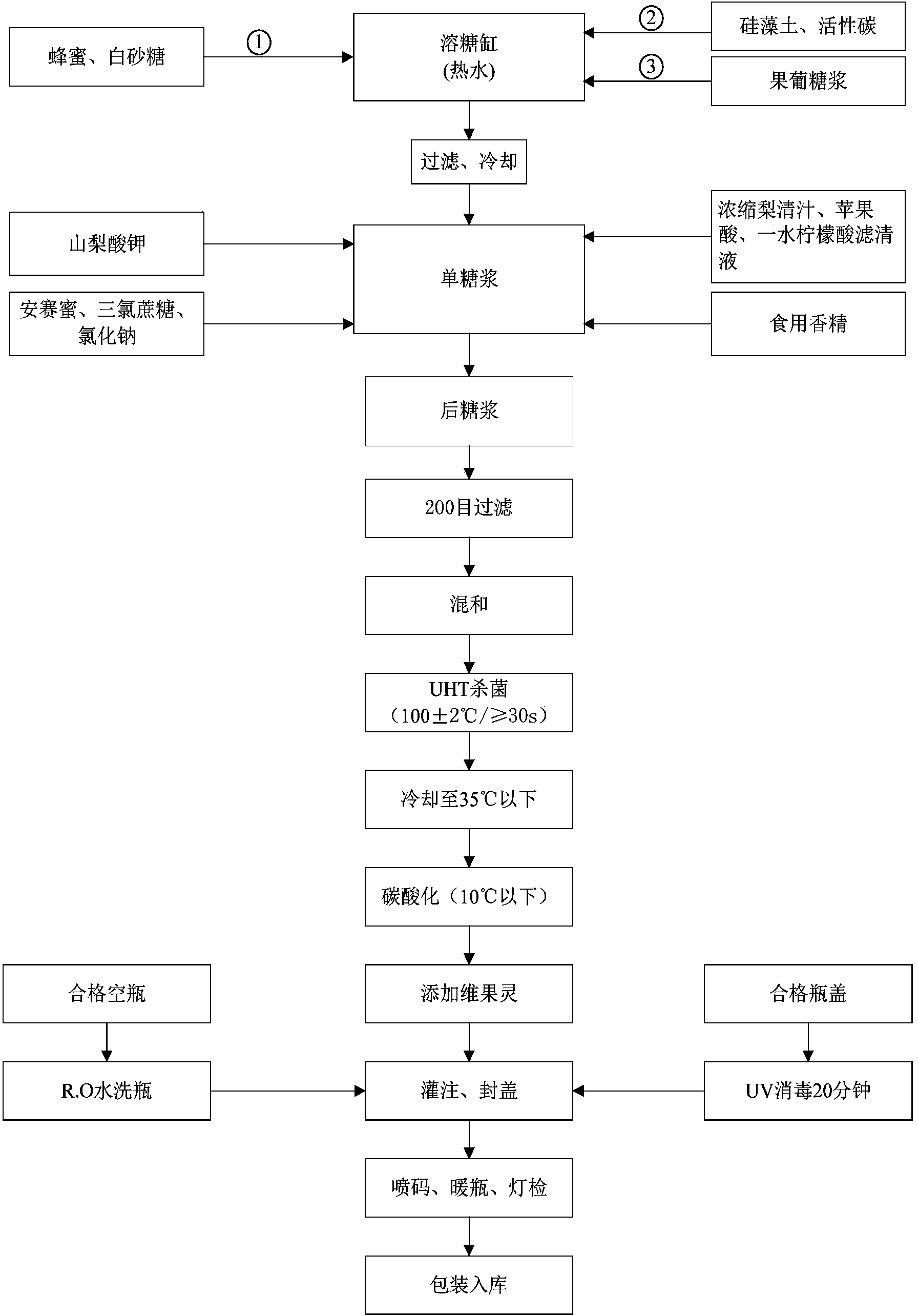

[0030] Such as figure 1 Shown, a kind of preparation method containing sparkling fruit juice beverage, comprises the following steps:

[0031] 1) Treatment of white granulated sugar and fructose syrup: take an appropriate amount of process water and heat it above 90°C, add 50g of white granulated sugar, appropriate amount of diatomaceous earth, and activated carbon, and keep it warm at 87±2°C for 25 minutes; then put in 31g of fructose syrup Insulate at 87±2°C for 1 minute; finally circulate and filter and pump into the blending tank.

[0032] 2) Solution preparation, take 1.1g of citric acid, 0.1g of malic acid, 0.1g of sodium chloride, 0.12g of acesulfame potassium, 0.035g of sucralose, and 0.3g of potassium sorbate and dissolve them in reverse osmosis water at room temperature, and pass through 200 mesh Filter to remove impurities in the raw material.

[0033] 3) Blending, start the stirring of the blending tank, first add potassium sorbate solution and stir for 5 minutes...

Embodiment 2

[0039] A method for preparing a carbonated fruit juice beverage, the preparation steps of which are basically the same as in Example 1, the difference being that the formula has been properly adjusted. In the present embodiment, each L fruit juice drink contains: white granulated sugar 53g, fructose syrup 28g, concentrated apple juice 18g, sucralose 0.03g, acesulfame potassium 0.08g, sodium chloride 0.13g, citric acid 0.9g, malic acid 0.2g, 0.25g potassium sorbate, 0.6g food essence, 0.09g virgolin.

Embodiment 3

[0041] A method for preparing a carbonated fruit juice beverage, the preparation steps of which are basically the same as in Example 1, the difference being that the formula has been properly adjusted. In this embodiment, each L fruit juice drink contains: 48g of white granulated sugar, 35g of fructose syrup, 19g of concentrated apple juice, 0.038g of sucralose, 0.13g of acesulfame potassium, 0.16g of sodium chloride, 1.2g of citric acid, and 1.2g of malic acid 0.3g, 0.32g of potassium sorbate, 0.9g of food flavor, 0.1g of Vigoline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com