Wet-type electric precipitator and application method thereof

A technology of wet electrostatic precipitator and cathode line, which is applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of difficult hoisting, difficult maintenance, poor force uniformity of support beams, etc., to increase the effective dust collection area, Improve the efficiency of dust removal and reduce the effect of smoke blind area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can be obtained based on these drawings without creative work.

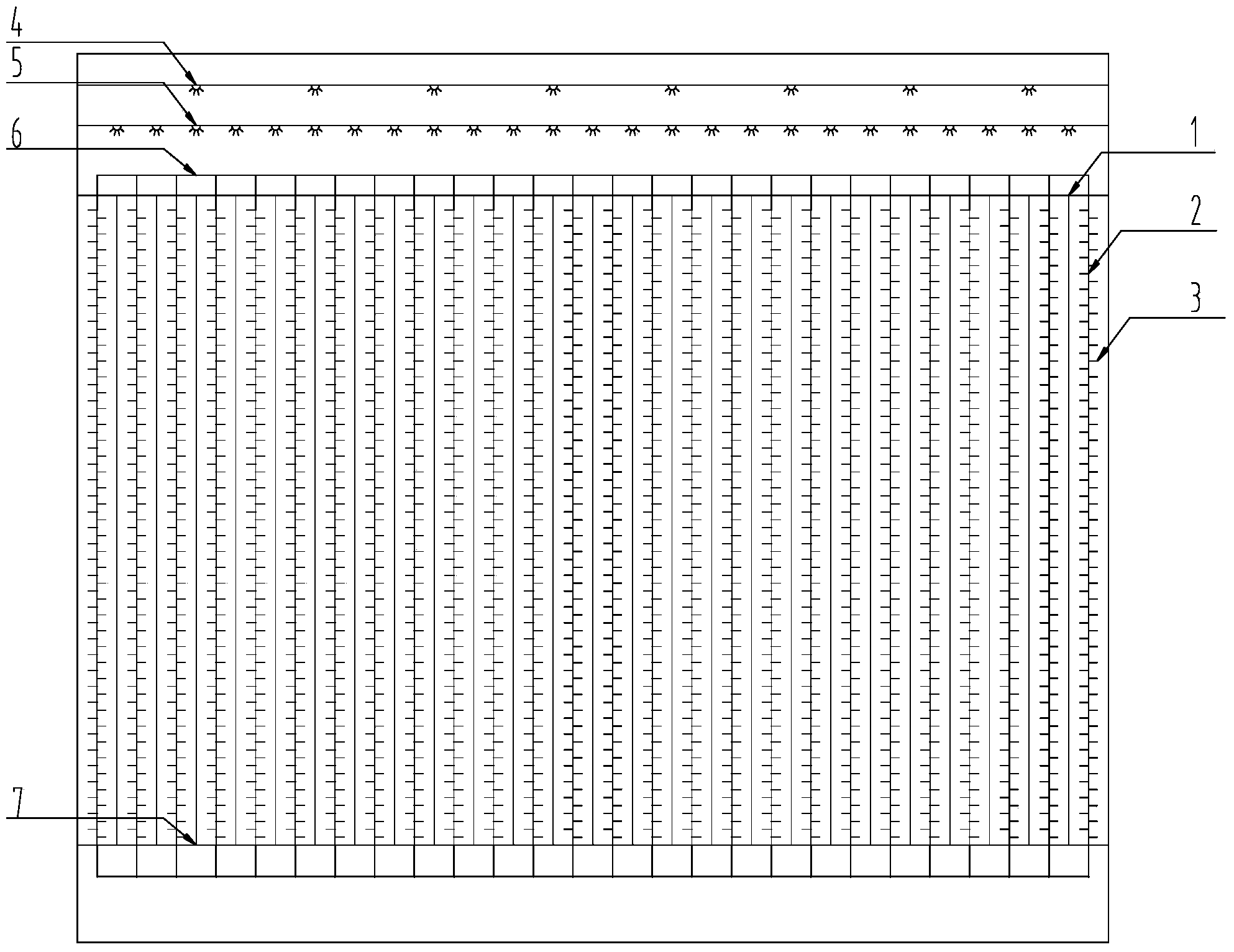

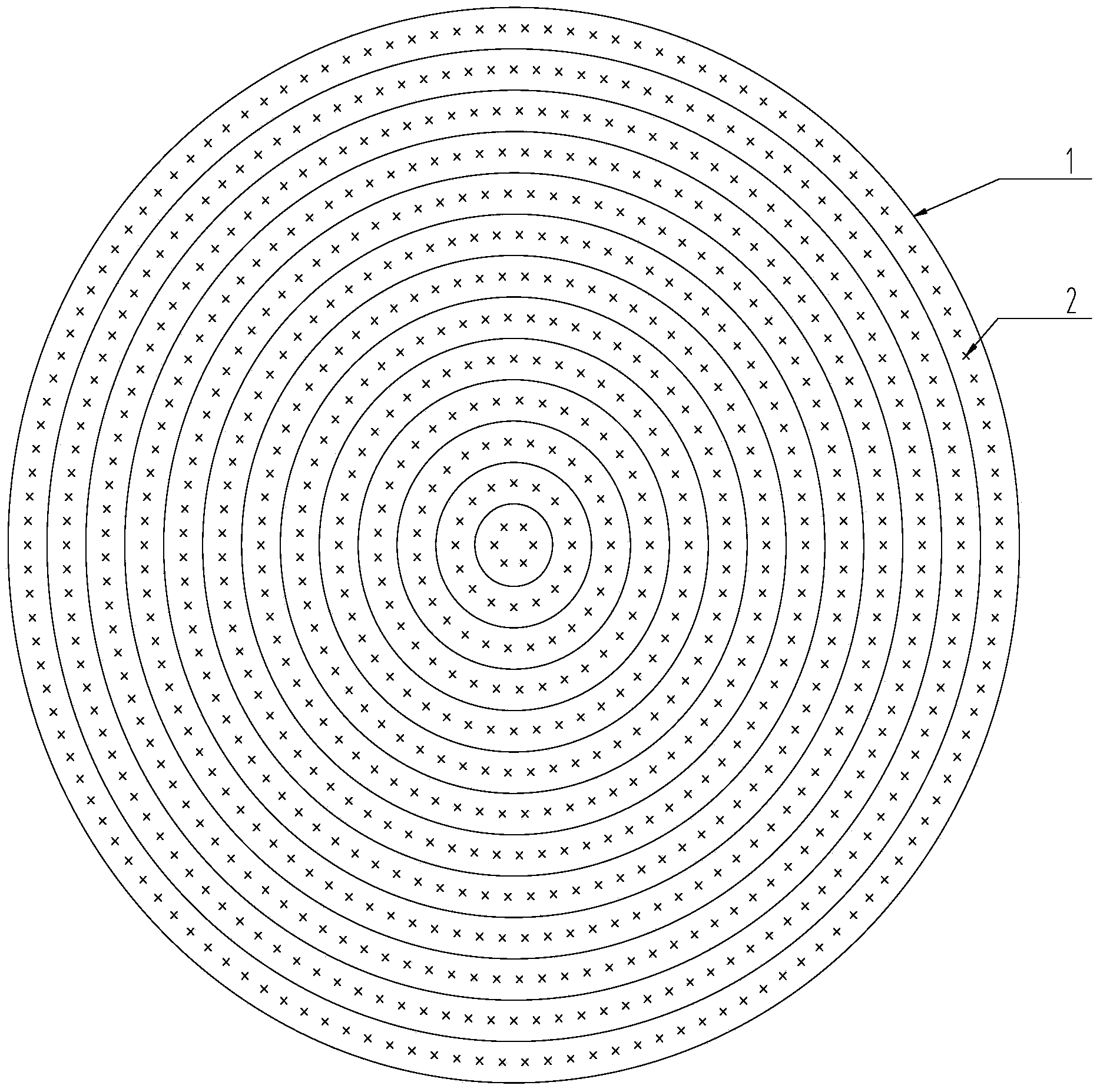

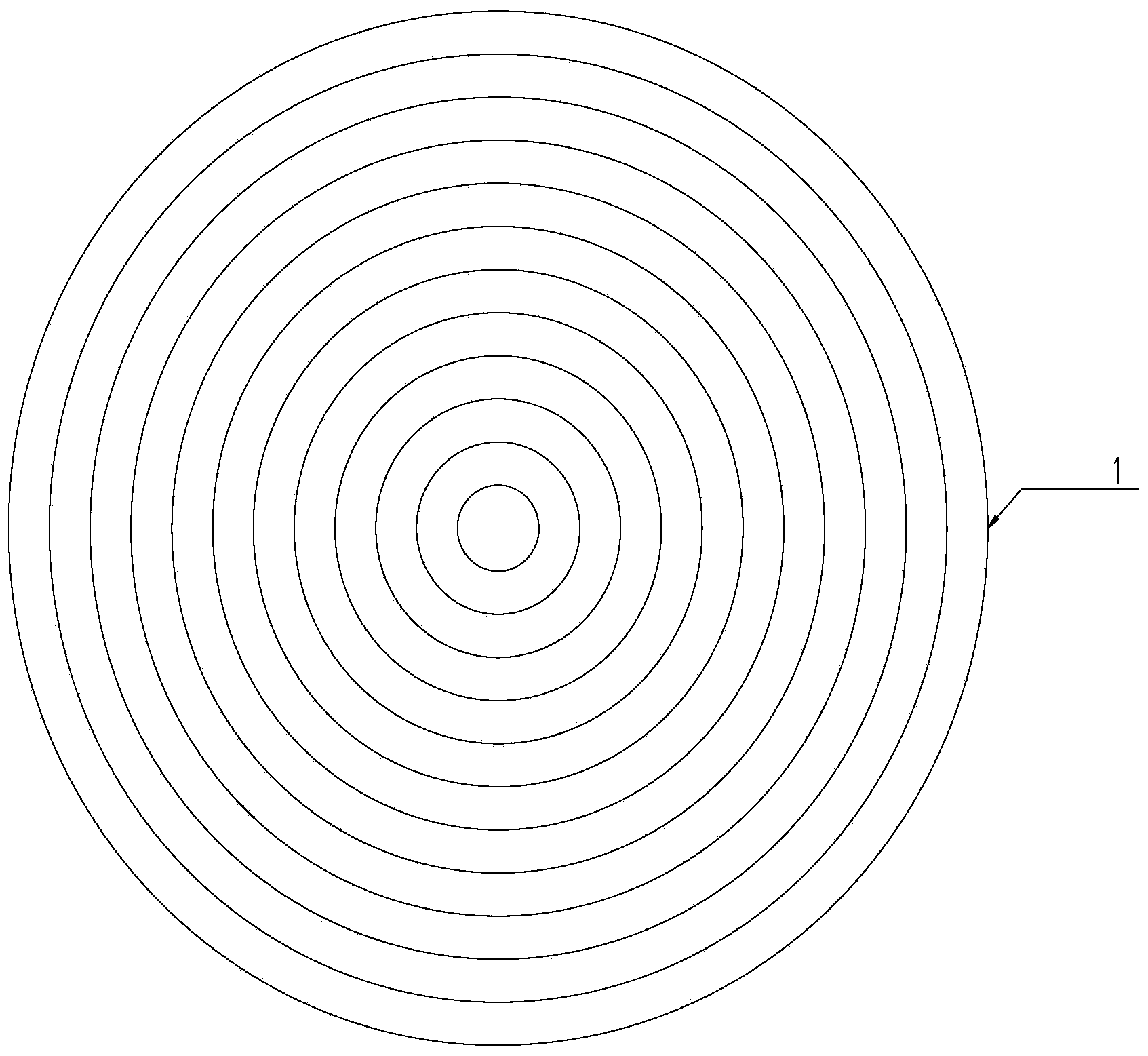

[0052] In the first embodiment of the present invention, the wet electrostatic precipitator includes: a casing, a plurality of cylindrical anode plates, a plurality of cathode wire rings, anode plate washing nozzles, and cathode wire washing nozzles; the plurality of cylindrical anode plates are Concentric distribution of different diameters; the cathode wire ring is a circularly distributed cathode wire, which is arranged at intervals from the cylindrical anode plate; the anode plate flushing nozzle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com