Semi-automatic lining core equipment

A semi-automatic and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of many manual participation components, reduce crimping efficiency, waste crimping waiting, etc., to increase the unloading efficiency, increase the degree of automation, Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

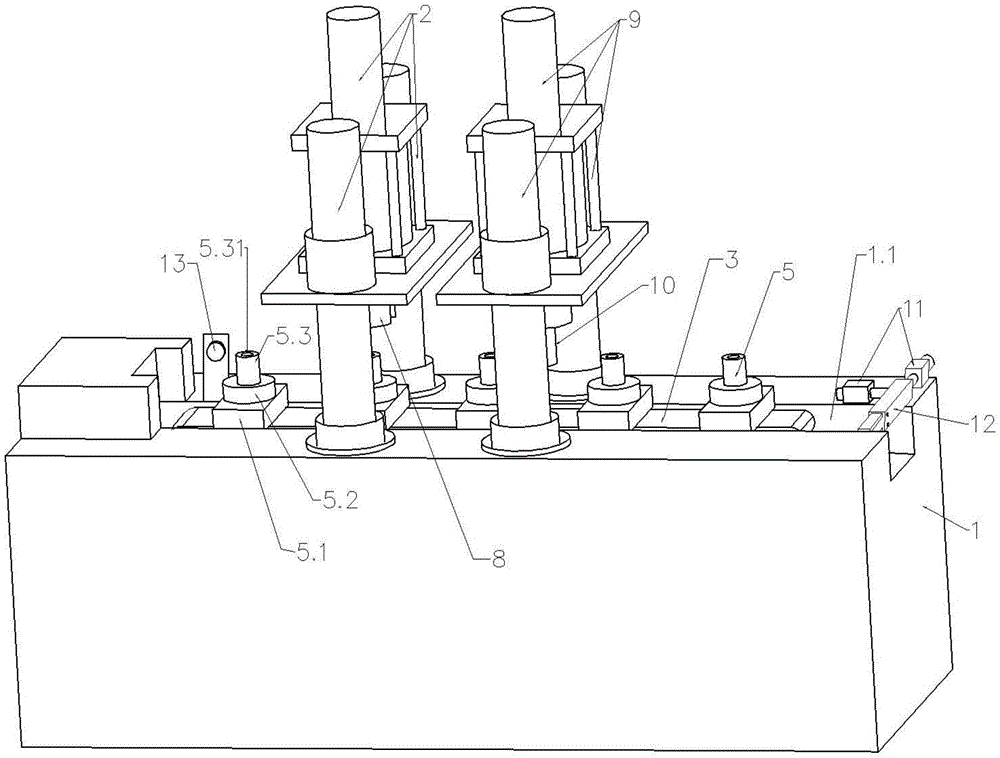

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

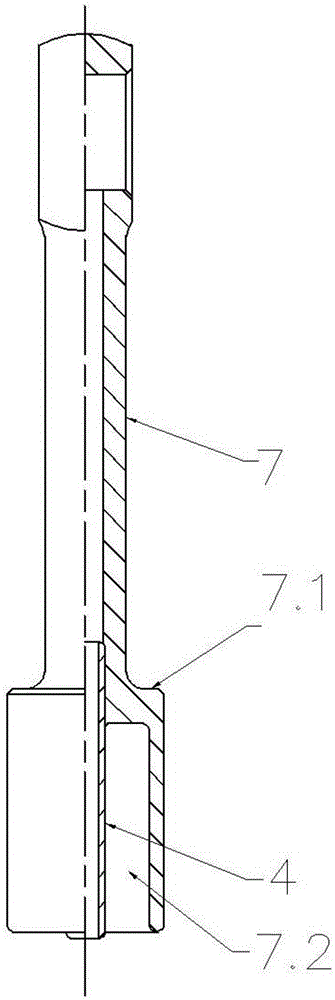

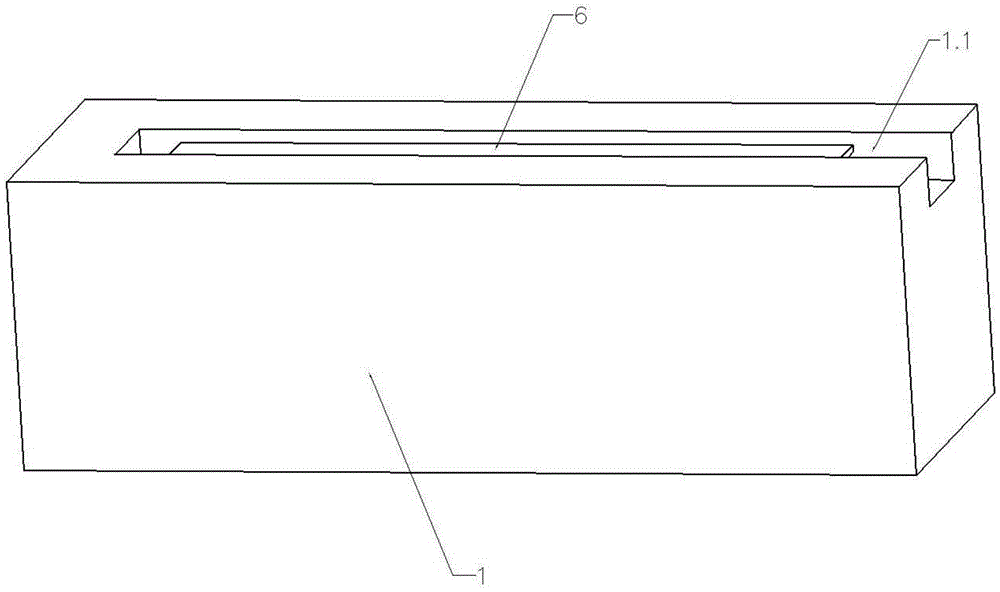

[0020] As shown in the figure, the semi-automatic lining core pressing equipment of the present invention includes a machine base 1, a pulley transmission mechanism installed in the Connect to cylinder 2. A plurality of clamping seats 5 for clamping the lining core 4 are installed on the transmission belt 3 of the pulley transmission mechanism.

[0021] In this embodiment, the clamping seats 5 are installed on the transmission belt at equal intervals. The pulley transmission mechanism consists of two pulleys and a transmission belt, one of which is driven by the output shaft of the motor to rotate, and the other pulley is a driven pulley, and the transmission belt is set on the two pulleys to realize transmission with the rotation of the pulley. .

[0022] The base 1 is provided with an opening 1.1 for the clamping base 5 to protrude from the top of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com