Chamfering machine for bent wood

A chamfering machine and bending technology, applied in the field of chamfering machines, can solve the problems of inconvenient processing of curved wood and four-corner chamfering of wood that cannot be bent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

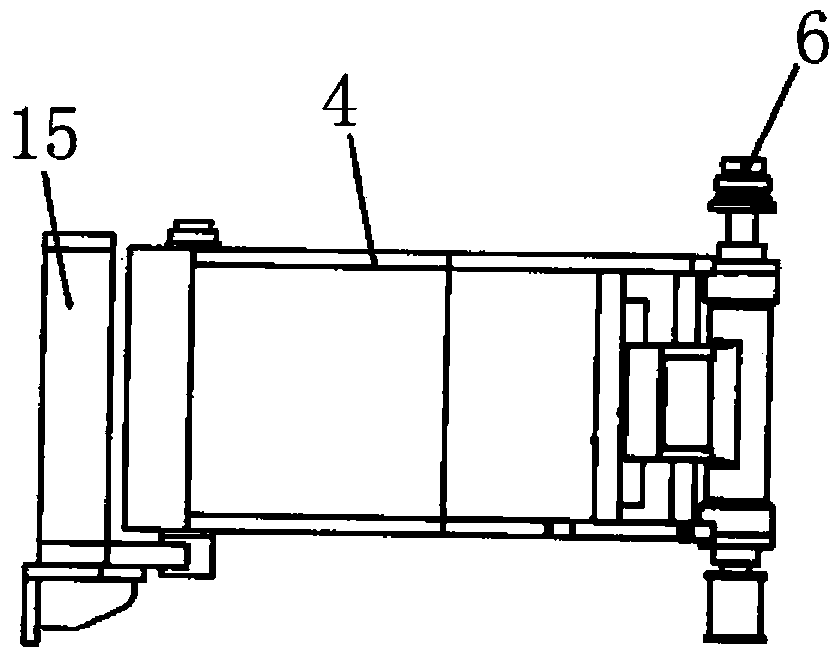

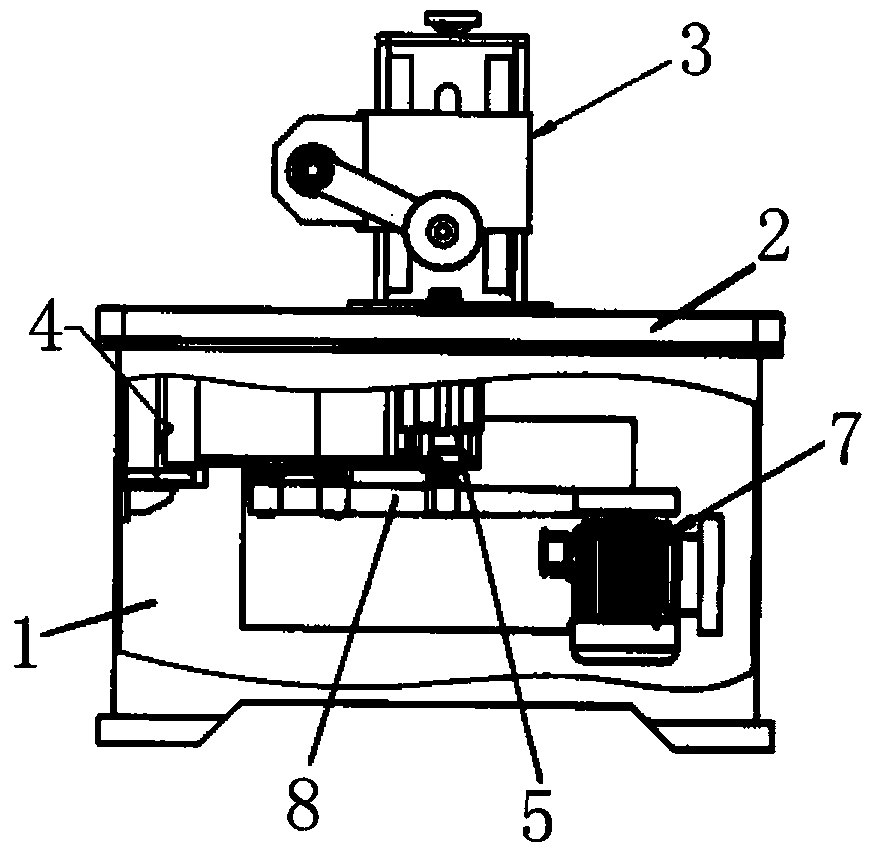

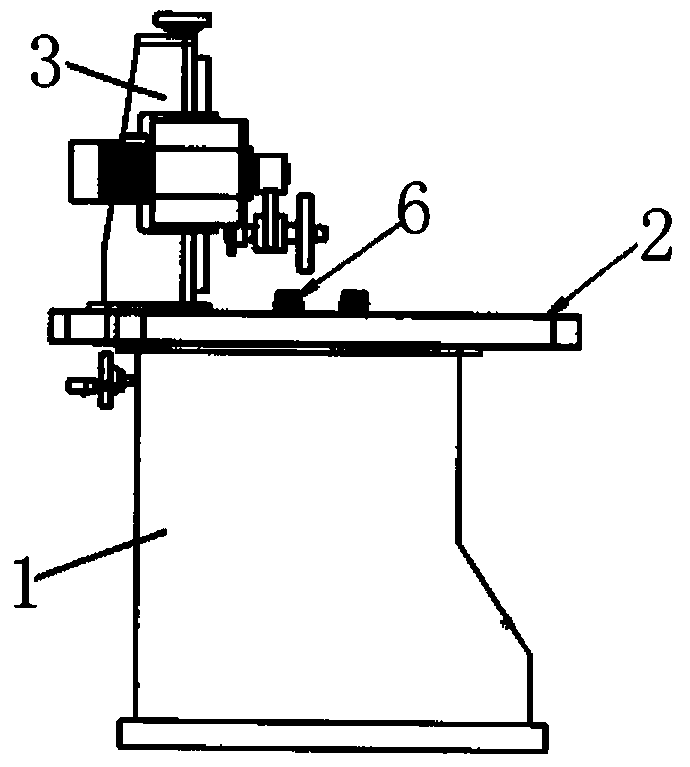

[0017] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, the present invention is provided with a workbench 2 on the upper part of the frame 1, and a press feeding assembly 3 is provided in the middle part of one side of the upper plane of the workbench 2, The swinging tool rest 4 and the fixed tool rest 5 are arranged at the bottom of the workbench 2, and the arcing tool head 6 on the swinging tool rest 4 and the fixed tool rest 5 is inserted into the workbench 2, and the bottom surface of the arcing tool head 6 is inserted into the workbench 2. Flush with the upper plane of the worktable 2 , the drive motor 7 is arranged on the inner side of the frame 1 , and the pulley of the drive motor 7 is connected with the pulleys on the swing tool rest 4 and the fixed tool rest 5 through the belt 8 . The pressing and feeding assembly 3 is composed of a bracket 9, a transmission reducer 10, a transmission pressure wheel 11 and a material pressing cylinder 12. A slider 13 is provided on one sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap