A kind of automobile bumper mold

A technology for automobile bumpers and molds, applied in the field of plastic molds and molds, can solve the problems of easy bending deformation of the inner block, dark printing on the appearance of the product, affecting the appearance of the product, etc., and achieves stable filling of the cavity, beautiful molding, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

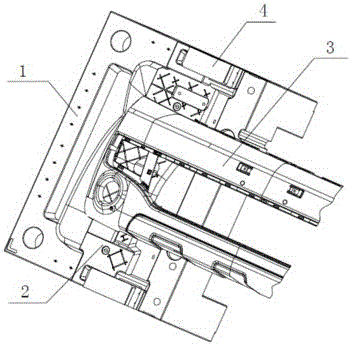

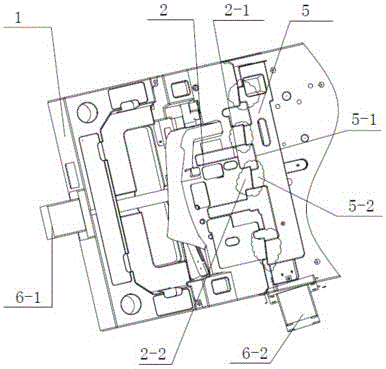

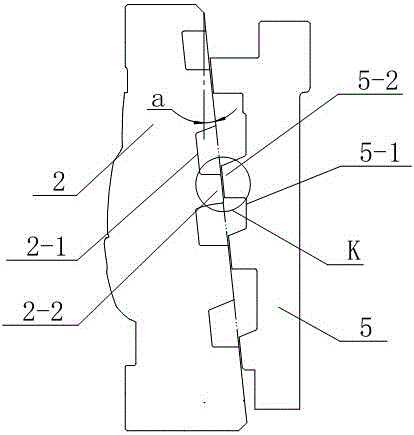

[0023] see figure 2 , The present invention includes an inner drawing block 2, a wedging block 5 and a driving device. The bumper mold includes a mold base 1, and a groove is provided on the mold base 1. The inner drawing block 2 and the wedging block 5 are mutually fitted and arranged in the groove of the mold base, and the inner drawing block 2 and the wedging block 5 are matched. The maximum width of the device is smaller than the width of the groove, and the driving device is arranged on the mold base.

[0024] The driving device includes a first oil cylinder 6-1 and a second oil cylinder 6-2, wherein the first oil cylinder 6-1 is used for pushing and pulling the inner block 2 to slide in the width direction; the second oil cylinder 6-2 is used for pushing and pulling the wedging Block 5 slides in the length direction. The cylinder body of the first oil cylinder 6-1 is arranged along the width direction of the mold base 1, and is fixedly installed on the outer wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com